Are you gearing up for a career in Embroidery Cutter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Embroidery Cutter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

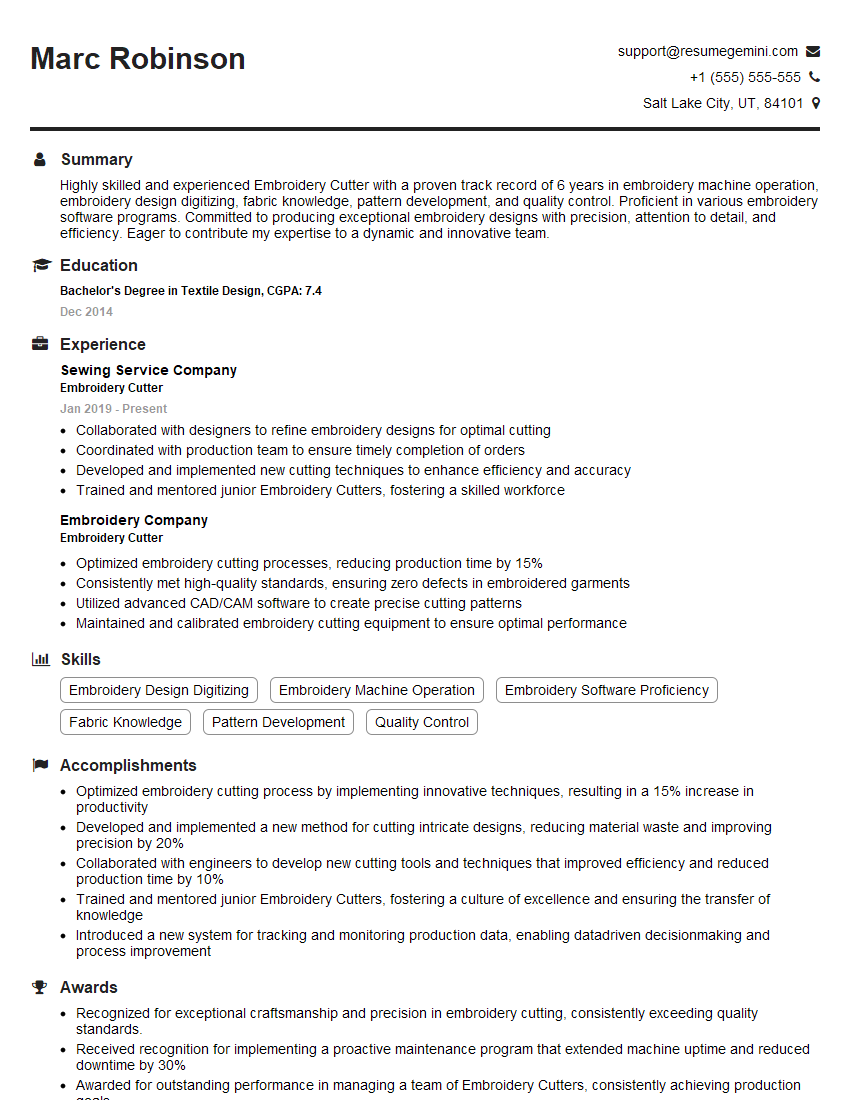

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Embroidery Cutter

1. Can you describe the process of setting up and operating an embroidery cutting machine?

The process of setting up and operating an embroidery cutting machine involves several steps:

- Mount the embroidery fabric or garment onto the machine’s hoop or frame.

- Load the embroidery design file into the machine’s software.

- Align the fabric or garment with the embroidery design.

- Set the cutting parameters, such as blade speed, depth, and pressure.

- Start the cutting process.

- Monitor the cutting process to ensure accuracy and quality.

- Remove the finished embroidery from the machine.

2. What are the most important factors to consider when selecting an embroidery cutting blade?

- Blade material: The blade material, such as tungsten carbide or steel, affects its durability and cutting performance.

- Blade shape: Different blade shapes, such as round, square, or V-shaped, are suitable for various types of fabrics and embroidery designs.

- Blade size: The blade size, including its diameter and thickness, determines the cutting depth and accuracy.

- Blade speed: The blade speed, measured in revolutions per minute (RPM), affects the cut quality and efficiency.

- Blade sharpness: A sharp blade ensures clean and precise cuts, reducing the risk of fraying or damage to the fabric.

3. How do you troubleshoot common problems that may arise while using an embroidery cutting machine?

- Fabric puckering or distortion: Adjust the fabric tension settings, use a stabilizer, or re-hoop the fabric.

- Uneven or jagged cuts: Check the blade sharpness, adjust the cutting parameters, or calibrate the machine.

- Blade breakage: Inspect the blade for damage, replace it if necessary, and ensure the blade is properly mounted.

- Machine vibration or noise: Check the machine’s components for loose connections, lubricate moving parts, or adjust the cutting speed.

- Software errors: Restart the software, check for updates, or consult the manufacturer’s troubleshooting guide.

4. Can you explain the different types of embroidery cutting techniques and their applications?

- Kiss cutting: Cuts through the top layer of fabric, leaving the backing intact, suitable for delicate fabrics and appliqués.

- Full cutting: Cuts through all layers of fabric, ideal for creating intricate designs and removing excess fabric.

- Scoring: Creates a shallow cut into the fabric, used for marking registration points or guiding manual cutting.

- Perforation: Punches small holes into the fabric along a design, allowing for easy tearing or stitching.

- Slitting: Makes straight cuts through the fabric, used for creating buttonholes or vents.

5. How do you ensure the accuracy and precision of embroidery cuts?

- Proper machine calibration: Regularly calibrate the machine to maintain accurate cutting.

- Precise fabric alignment: Align the fabric carefully with the embroidery design to prevent shifting or distortion.

- Optimal cutting parameters: Experiment with different cutting parameters to find the optimal settings for the specific fabric and design.

- Sharp cutting blades: Use sharp blades to ensure clean and precise cuts without fraying or damage.

- Quality control measures: Implement quality control measures, such as checking cut samples and inspecting finished products, to ensure accuracy.

6. What safety precautions should be taken when operating an embroidery cutting machine?

- Wear appropriate safety gear, including safety glasses, earplugs, and gloves.

- Keep the work area clean and organized to prevent tripping or accidents.

- Inspect the machine regularly for any potential hazards, such as loose wires or damaged components.

- Never reach into the cutting area while the machine is operating.

- Follow the manufacturer’s operating instructions and safety guidelines carefully.

7. How do you maintain and service an embroidery cutting machine to ensure optimal performance?

- Regular cleaning: Clean the machine regularly to remove dust, debris, and fabric scraps.

- Blade maintenance: Replace dull or damaged blades promptly to maintain cutting quality.

- Lubrication: Lubricate moving parts according to the manufacturer’s recommendations.

- Calibration checks: Perform regular calibration checks to ensure accuracy and precision.

- Software updates: Install software updates to fix bugs and improve machine functionality.

8. Can you describe the different types of fabrics that are suitable for embroidery cutting and their unique requirements?

- Woven fabrics: Woven fabrics, such as cotton, linen, and denim, are typically suitable for embroidery cutting, but may require stabilizers for delicate designs.

- Knitted fabrics: Knitted fabrics, such as jersey and fleece, require careful handling to prevent stretching or distortion during cutting.

- Specialty fabrics: Specialty fabrics, such as leather, faux leather, and vinyl, may require specific blade types or cutting parameters.

9. What are the advantages of using an embroidery cutting machine over manual cutting methods?

- Increased accuracy: Embroidery cutting machines provide precise and consistent cuts, eliminating the risk of errors.

- Improved efficiency: Machines can cut multiple layers of fabric simultaneously, increasing productivity.

- Versatility: Machines can cut a wide range of fabrics and create intricate designs.

- Labor savings: Machines reduce the need for manual cutting, saving labor costs and allowing employees to focus on other tasks.

10. Can you explain how embroidery cutting techniques can be used to create unique and innovative designs?

- Layer cutting: Cutting multiple layers of fabric with varying designs creates depth and dimension.

- Reverse appliqué: Cutting away the top layer of fabric to reveal a design on a lower layer.

- Fringe cutting: Creating decorative fringes by cutting the fabric at an angle.

- Perforation cutting: Creating intricate patterns by punching holes in the fabric.

- Combination cutting: Using multiple cutting techniques together to achieve complex and visually striking designs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Embroidery Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Embroidery Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Embroidery Cutter is responsible for cutting and preparing fabric or other materials for embroidery. Key job responsibilities of an Embroidery Cutter include:1.Preparing Fabrics and Materials

Preparing fabrics and other materials for embroidery involves inspecting and measuring fabrics to ensure they meet specifications. Embroidery Cutters also cut fabrics according to patterns or designs, and fuse interfacing materials to stabilize delicate fabrics.

2. Cutting and Trimming

Cutting and trimming involves using sharp knives or scissors to cut fabric and other materials precisely. Embroidery Cutters also trim excess threads or materials to create a finished product.

3. Embossing and Stitching

Embossing and stitching involve using machinery to create raised designs or patterns on fabrics. Embroidery Cutters also stitch appliqués or other embellishments onto fabrics.

4. Maintaining Equipment

Maintaining equipment involves cleaning and lubricating machinery, and replacing needles or blades as needed. Embroidery Cutters also perform minor repairs to ensure equipment is in good working condition.

Interview Tips

To ace an interview for an Embroidery Cutter position, it is important to highlight your skills and experience in cutting and preparing fabrics for embroidery. Some interview tips and hacks include:

1. Research the Company and Role

Research the company and the specific role to understand their embroidery process and the skills and experience they are looking for. This will help you tailor your answers to the interviewer’s questions.

2. Highlight Your Skills and Experience

Highlight your skills and experience in cutting and preparing fabrics for embroidery. Quantify your accomplishments whenever possible to demonstrate the impact of your work. For example, you could mention the number of pieces you cut or the percentage of materials you saved by optimizing cutting techniques.

3. Show Your Knowledge of Equipment

Show your knowledge of embroidery equipment, including knives, scissors, and machinery. Explain how you use this equipment to cut and prepare fabrics accurately and efficiently.

4. Be Prepared to Answer Technical Questions

Be prepared to answer technical questions about embroidery techniques, such as the different types of stitches and how to create specific designs. You should also be familiar with the safety precautions and quality standards related to embroidery.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Embroidery Cutter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.