Are you gearing up for a career in Shearing Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Shearing Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

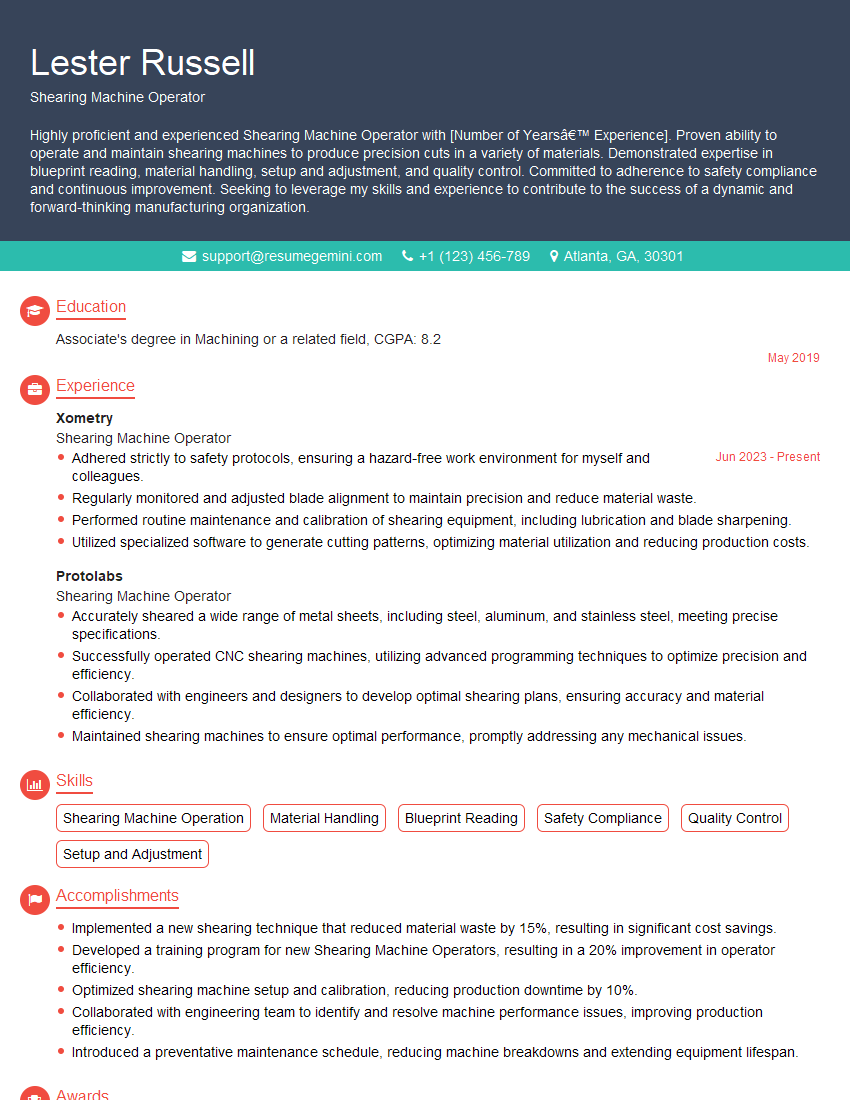

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shearing Machine Operator

1. What are the different types of shearing machines and their applications?

There are various types of shearing machines, each designed for specific applications:

- Guillotine Shears: Primarily used for straight cuts on sheet metal, these shears employ a blade that descends vertically to cut the material.

- Rotary Shears: Featuring a rotating blade, these shears are ideal for cutting curves, circles, and irregular shapes in sheet metal.

- Angle Shears: Designed to cut angles in sheet metal, these shears have a blade that can be adjusted to different angles.

- Nibblers: These shears use a punching motion to create intricate shapes and patterns in sheet metal.

2. How do you maintain the accuracy of shearing machines?

Maintaining shearing machine accuracy requires several key measures:

- Regular Cleaning: Remove any debris or metal shavings that can accumulate on the machine to ensure precise cuts.

- Blade Sharpening: Periodically sharpen the blades to maintain their sharpness and prevent tearing or uneven cuts.

- Alignment Adjustments: Regularly check and adjust the alignment of the blades to ensure they are parallel and perpendicular to the material.

- Gauge Calibration: Calibrate the machine’s gauges to ensure accurate measurement and cutting of materials.

3. What are the safety precautions to observe when operating shearing machines?

To ensure safety during shearing machine operation:

- Wear Proper Attire: Always wear appropriate clothing, including safety glasses, gloves, and hearing protection.

- Clear Work Area: Maintain a clean and organized work area free from tripping hazards and obstructions.

- Inspect Machine Regularly: Inspect the machine thoroughly before each use to identify any potential issues.

- Secure Material: Ensure that the material being cut is securely held in place to prevent movement during cutting.

- Follow Lockout/Tagout Procedures: When the machine is not in operation, implement lockout/tagout procedures to prevent unauthorized use.

4. How do you troubleshoot common shearing machine problems?

To troubleshoot common shearing machine problems effectively:

- Inaccurate Cuts: Check blade alignment, sharpness, and gauge calibration. Adjust or replace components as needed.

- Tearing or Ripping: Inspect blades for dullness or damage. Replace or sharpen blades if necessary.

- Machine Vibration: Examine machine for loose bolts or components. Tighten or replace as required.

- Overheating: Ensure proper lubrication and cooling of the machine. Inspect for blockages or leaks in lubrication systems.

- Electrical Faults: Check electrical connections, wiring, and components for damage or loose connections. Refer to qualified electrician if necessary.

5. How do you optimize shearing machine performance?

To optimize shearing machine performance:

- Use Sharp Blades: Maintain sharp blades to ensure clean and precise cuts, reducing material waste.

- Regular Maintenance: Perform regular lubrication, cleaning, and inspections to prevent breakdowns and extend machine life.

- Efficient Material Handling: Use proper material handling equipment to efficiently load and unload materials, minimizing downtime.

- Operator Training: Ensure operators are well-trained on the machine’s operation, maintenance, and safety procedures.

- Process Optimization: Analyze cutting processes to identify areas for improvement, such as optimizing blade angles or material thickness.

6. What is the difference between shearing and blanking operations?

Shearing: Cuts the material along a straight line, leaving a clean edge.

Blanking: Punches out a specific shape or design from the material, leaving a clean edge and a separated part.

7. Explain the role of die clearance in shearing operations.

Die clearance is the gap between the shearing blades. It affects the quality and efficiency of the cut:

- Too Little Clearance: Can lead to blade damage, increased force requirements, and poor cut quality.

- Too Much Clearance: Can result in excessive material deformation, burrs, and reduced cutting accuracy.

8. Describe the process of setting up a shearing machine for a specific cutting job.

Setting up a shearing machine for a specific cutting job involves several steps:

- Material Selection: Determine the material type, thickness, and grain direction.

- Blade Selection: Choose appropriate blades based on material and desired cut quality.

- Machine Adjustments: Set the blade gap, hold-down pressure, and machine speed according to material specifications.

- Test Cuts: Conduct test cuts to verify settings and ensure desired cut quality.

9. How do you ensure the safety of others while operating a shearing machine?

Ensuring the safety of others while operating a shearing machine requires:

- Clear Work Area: Keep the work area free from obstacles and potential hazards.

- Proper Fencing: Install appropriate fencing or guards around the machine to prevent unauthorized access.

- Warning Signs: Post clear warning signs around the machine indicating its operation and potential risks.

- Proper Training: Train all personnel in the vicinity on the machine’s operation and safety procedures.

10. How do you handle and store shearing machine blades to maintain their sharpness and longevity?

To handle and store shearing machine blades effectively:

- Proper Handling: Use proper lifting techniques and wear gloves to prevent cuts or damage during handling.

- Blade Storage: Store blades in a dry, climate-controlled environment to prevent corrosion.

- Protective Coating: Apply a protective coating to blades to minimize oxidation and maintain their sharpness.

- Regular Inspection: Periodically inspect blades for damage or dullness. Resharpen or replace blades as needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shearing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shearing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Shearing Machine Operators are responsible for operating and maintaining shearing machines, which are used to cut metal sheets and plates. They must be able to read blueprints and follow instructions, and they must have a good understanding of the principles of shearing. Some of the key job responsibilities of a Shearing Machine Operator include:

1. Operating the shearing machine

This includes setting up the machine, loading the metal sheets or plates, and operating the machine to cut the metal to the desired shape and size.

2. Maintaining the shearing machine

This includes cleaning and lubricating the machine, and performing minor repairs as needed.

3. Inspecting the finished product

This includes checking the cut metal for defects, and ensuring that it meets the customer’s specifications.

4. Following safety procedures

This includes wearing appropriate safety gear, and following all safety rules and regulations.

Interview Tips

Preparing for a job interview can be daunting, but there are some things you can do to increase your chances of success. Here are some interview tips for Shearing Machine Operators:

1. Research the company and the position

This will help you understand the company’s culture and values, and it will also give you a better idea of the specific requirements of the position.

2. Practice your answers to common interview questions

This will help you feel more confident and prepared during the interview.

3. Dress professionally

First impressions matter, so make sure you dress appropriately for the interview.

4. Be on time

Punctuality shows that you respect the interviewer’s time.

5. Be enthusiastic and positive

Employers are looking for candidates who are excited about the opportunity to work for their company. Show the interviewer that you are interested in the position and that you are confident in your abilities.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Shearing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.