Feeling lost in a sea of interview questions? Landed that dream interview for Needle Loom Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Needle Loom Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

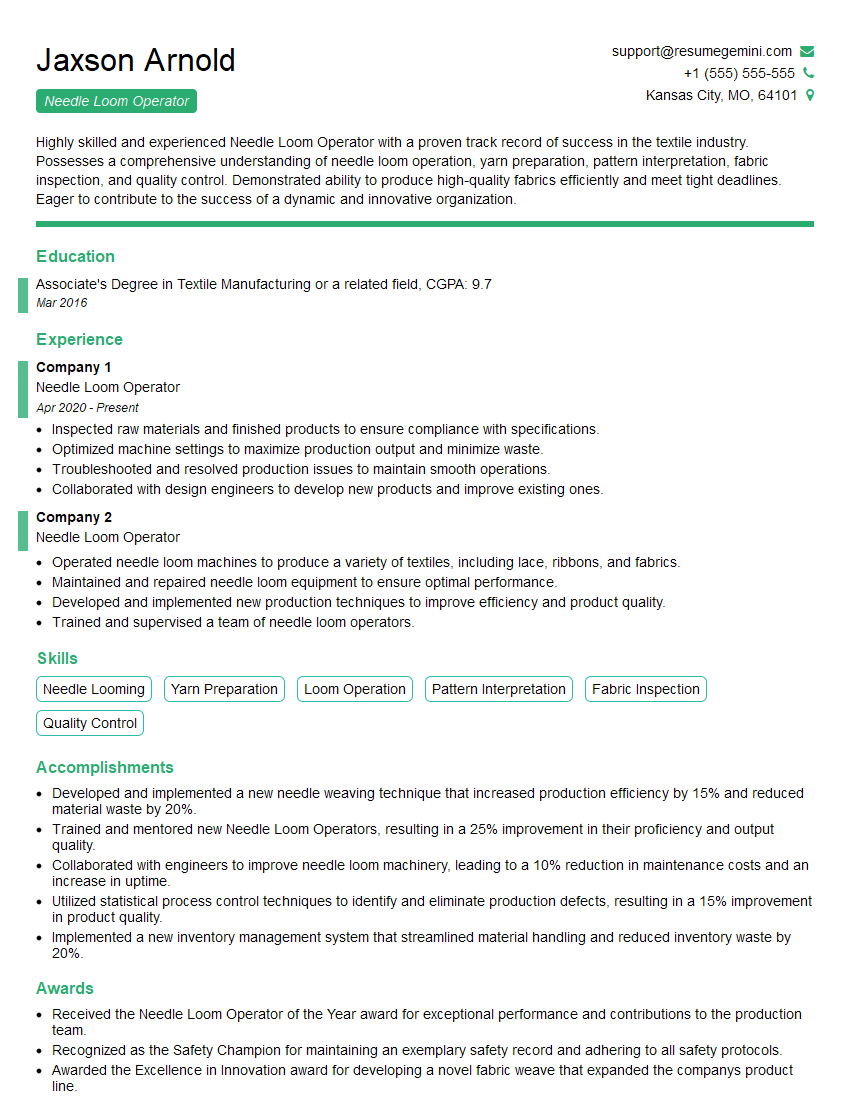

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Needle Loom Operator

1. Describe the process of setting up a needle loom machine for production.

The setup process for a needle loom machine for production involves several steps:

- Loading the yarn: The yarn is loaded onto the machine’s creels or cones, ensuring proper tension and alignment.

- Threading the needles: Each needle is individually threaded with the yarn, creating a series of loops that will form the fabric.

- Adjusting machine settings: The machine’s settings, such as needle density, stitch length, and tension, are adjusted to meet the specific product requirements.

- Testing and inspecting: A test run is performed to ensure that the machine is running smoothly and producing the desired fabric quality.

- Production start: Once the setup is complete and the machine is operating correctly, production can commence.

2. Explain the different types of needle loom machines and their applications.

Circular needle loom machines

- Produce cylindrical or tubular fabrics (e.g., socks, gloves, bandages) at high speeds.

- Suitable for knitting elastic and stretchable materials.

Flat needle loom machines

- Produce flat fabrics (e.g., sweaters, blankets, upholstery) with intricate patterns and textures.

- Offer more versatility in design and can accommodate thicker yarns.

Raschel needle loom machines

- Produce openwork or mesh fabrics (e.g., lace, net, tulle) with high precision.

- Create fabrics with unique textures and designs.

3. Describe the maintenance procedures for a needle loom machine.

Regular maintenance is crucial for ensuring optimal performance and longevity of a needle loom machine:

- Daily checks: Cleaning and inspecting the needles, yarn, and machine components for any damage or wear.

- Weekly lubrication: Oiling and greasing moving parts to reduce friction and prevent premature wear.

- Monthly maintenance: Thorough cleaning of the machine, including the needle bed, carriage, and drive system.

- Regular inspections: Scheduled inspections by a qualified technician to identify any potential issues early on.

4. What are the common problems that can occur during needle loom operation, and how do you troubleshoot them?

Common problems and troubleshooting steps:

- Yarn breakage: Check yarn tension, thread path, and needle condition.

- Dropped stitches: Inspect needles for damage, adjust machine settings, and check yarn quality.

- Fabric defects: Examine machine settings, yarn tension, and needle bed alignment.

- Machine stoppage: Check for power supply issues, loose connections, or mechanical failures.

5. Describe your experience in operating and maintaining needle loom machines.

In my previous role as a Needle Loom Operator, I was responsible for operating and maintaining a variety of needle loom machines. My duties included:

- Setting up and operating circular, flat, and Raschel needle loom machines.

- Conducting regular maintenance tasks, including cleaning, lubrication, and inspections.

- Troubleshooting and resolving operational issues to minimize downtime.

- Collaborating with engineers to optimize machine performance and product quality.

6. Explain the use of different types of yarns in needle loom production.

The type of yarn used in needle loom production significantly impacts the fabric’s characteristics:

- Natural fibers: Cotton, wool, and silk provide comfort, breathability, and durability.

- Synthetic fibers: Polyester, nylon, and spandex offer strength, elasticity, and wrinkle resistance.

- Blends: Combining different fibers creates fabrics with unique properties, such as softness, moisture-wicking, and colorfastness.

7. Describe the quality control measures implemented in needle loom production.

Quality control is essential to ensure the production of high-quality fabrics:

- Raw material inspection: Checking yarn quality, color consistency, and tensile strength.

- In-process inspections: Monitoring fabric appearance, stitch density, and dimensional accuracy.

- Final product inspection: Conducting thorough examinations to identify any defects or non-conformities.

- Documentation and traceability: Maintaining records of production parameters and test results for quality assurance.

8. Discuss the safety precautions that must be observed when operating needle loom machines.

Safety is paramount when working with needle loom machines:

- Proper attire: Wearing appropriate clothing, including protective gloves and safety glasses.

- Machine guarding: Ensuring that all moving parts are properly guarded to prevent contact with operators.

- Electrical safety: Checking for loose wires, damaged insulation, and proper grounding.

- Emergency procedures: Being familiar with emergency stop buttons and evacuation routes.

9. What are the environmental considerations involved in needle loom production?

Environmental sustainability is important in the textile industry:

- Yarn selection: Choosing yarns made from renewable or recycled materials.

- Waste reduction: Minimizing fabric waste through efficient cutting and sewing practices.

- Energy efficiency: Optimizing machine settings and using energy-efficient lighting.

- Water conservation: Implementing water-saving measures in dyeing and finishing processes.

10. How do you stay updated on the latest advancements in needle loom technology?

Staying abreast of industry advancements is crucial:

- Trade shows and conferences: Attending industry events to learn about new technologies and trends.

- Technical publications: Reading journals and articles on needle loom technology.

- Online resources: Utilizing online forums and websites for industry-related information.

- Collaboration with manufacturers: Engaging with needle loom machine manufacturers for updates and technical support.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Needle Loom Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Needle Loom Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Needle Loom Operators play a crucial role in the manufacturing process, operating specialized machines to create various types of textiles. Their responsibilities encompass:

1. Machine Operation

Operate needle looms to produce diverse textile products, ensuring smooth and efficient operation of the machinery.

- Monitor machine functionality, making adjustments as necessary to maintain optimal performance and product quality.

- Troubleshoot and resolve operational issues promptly to minimize downtime and maintain production efficiency.

2. Quality Control

Inspect the produced textiles thoroughly for any defects or inconsistencies, adhering to established quality standards.

- Identify and rectify any errors or flaws in the fabric, ensuring the final products meet customer specifications.

- Maintain detailed records of quality checks and inspections, providing documentation for production and quality control purposes.

3. Production Management

Manage the production process, ensuring timely completion of orders and meeting production targets.

- Set up and prepare the loom for production, selecting the appropriate materials and settings based on the desired fabric specifications.

- Monitor production rates and adjust loom parameters as needed to optimize output and minimize waste.

4. Maintenance and Cleaning

Perform regular maintenance and cleaning tasks to ensure the longevity and optimal functioning of the needle loom.

- Clean and lubricate machine components, following established maintenance schedules.

- Inspect loom parts for wear or damage, reporting any issues promptly for timely repairs.

Interview Tips

To enhance your chances of success in an interview for a Needle Loom Operator position, consider the following tips:

1. Research and Preparation

Familiarize yourself with the company, their products, and the specific role you are applying for.

- Visit the company’s website to gather information about their business, values, and industry standing.

- Review the job description carefully, noting the key responsibilities, skills, and experience required.

2. Highlight Relevant Experience

Emphasize your experience in operating needle looms, including specific examples of your accomplishments.

- Quantify your achievements whenever possible, using metrics to demonstrate your impact and efficiency.

- Be prepared to discuss your experience in maintaining and repairing needle looms, if applicable.

3. Demonstrate Quality Consciousness

Showcase your commitment to producing high-quality textiles, highlighting your attention to detail and ability to maintain rigorous quality standards.

- Share examples of your success in identifying and rectifying defects or errors in textiles.

- Discuss your understanding of quality control processes and your experience in maintaining documentation.

4. Emphasize Production Management Skills

Demonstrate your ability to manage the production process effectively, ensuring timely order completion and meeting production targets.

- Provide examples of how you have optimized production rates and minimized waste through efficient setup and loom adjustments.

- Discuss your experience in working with supervisors and other team members to achieve production goals.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Needle Loom Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!