Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Quilter Fixer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Quilter Fixer so you can tailor your answers to impress potential employers.

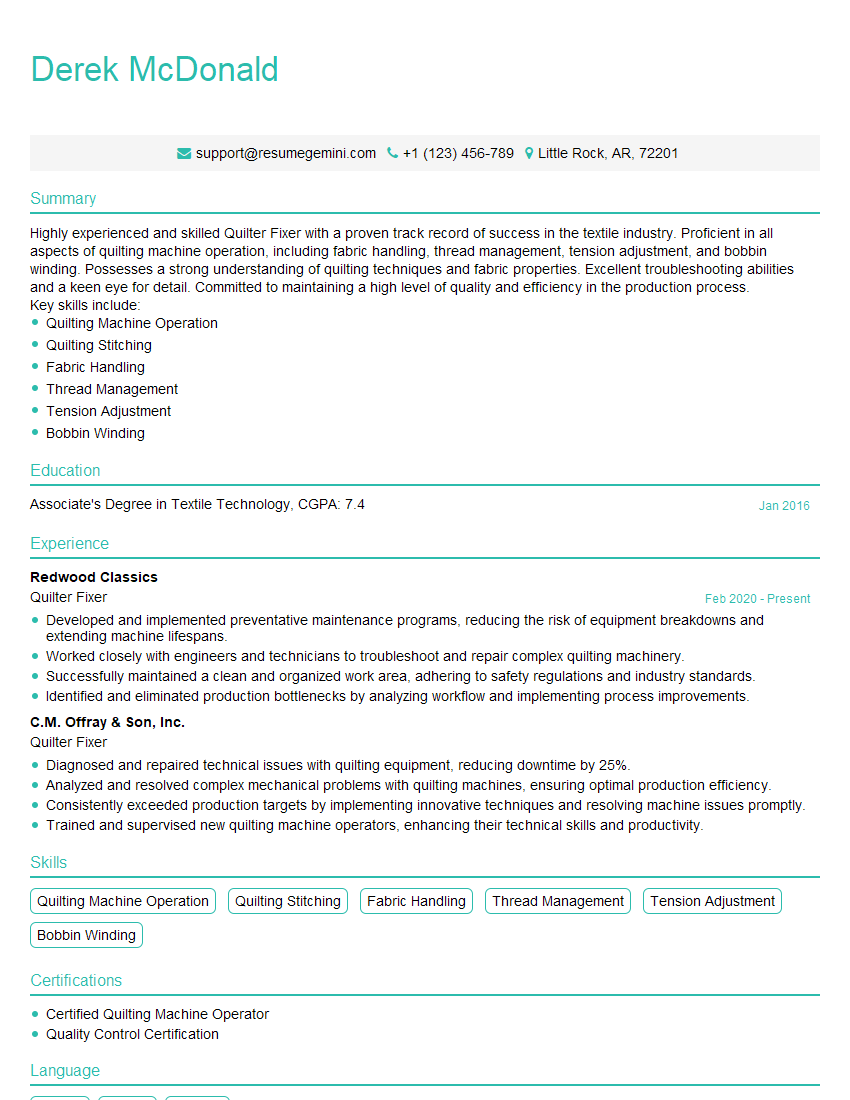

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Quilter Fixer

1. What are the common quilting techniques that you are familiar with?

As a Quilter Fixer, I am well-versed in various quilting techniques, including:

- Machine Quilting: Using a sewing machine to stitch layers of fabric together, creating various patterns and designs.

- Hand Quilting: Manually sewing layers of fabric together using a needle and thread, resulting in intricate and personalized designs.

- Appliqué: Sewing or fusing fabric pieces onto a background fabric to create images or patterns.

- Embroidery: Decorating quilt layers with decorative stitches using a sewing machine or by hand.

- Patchwork: Combining different fabric pieces into a larger design, often using leftover fabrics or specific patterns.

2. How do you inspect and troubleshoot quilting equipment to ensure optimal performance?

Preventive Maintenance

- Regularly cleaning and lubricating moving parts.

- Inspecting cables and cords for damage.

- Testing tension settings and adjusting as needed.

Troubleshooting

- Identifying unusual noises, vibrations, or odors.

- Diagnosing electrical issues using a multimeter.

- Checking for loose connections or worn parts.

3. What are the different types of quilting fabrics, and how do you determine the appropriate fabric for a specific quilt project?

The choice of quilting fabric depends on several factors:

- Fiber Content: Natural fibers (cotton, wool, silk) offer breathability and comfort, while synthetic fibers (polyester, nylon) provide durability and resistance to fading.

- Weight: Fabric weight ranges from lightweight (voile, lawn) to heavyweight (canvas, denim), affecting the drape and warmth of the quilt.

- Weave: Plain weave (calico, muslin) creates a balanced look, while twill weave (gabardine, denim) produces a diagonal pattern.

- Pattern: Quilting fabrics come in a wide range of prints, solids, and textures, allowing for creative expression.

4. What are the different methods for finishing a quilt, and which method would you recommend for a specific type of quilt?

Finishing options include:

- Binding: Encasing the exposed edges of the quilt with a strip of fabric, adding durability and a decorative touch.

- Facing: Using a backing fabric to cover and protect the back of the quilt, providing a clean and professional look.

- Flange Binding: Creating a wider border around the quilt using a contrasting fabric, adding visual interest.

- Mitre Binding: Joining binding strips at 45-degree angles, resulting in a polished and elegant finish.

5. How do you handle repairs and alterations on quilts, and what techniques do you employ?

Repair and alteration techniques may include:

- Patching: Replacing damaged or worn areas with new fabric, matching the pattern and color.

- Darning: Mending holes or tears by weaving threads through the fabric, creating a seamless repair.

- Embroidery: Covering up imperfections or embellishing damaged areas with decorative stitches.

- Resizing: Altering the size of a quilt by adding or removing rows or blocks, adjusting the overall dimensions.

6. What are the safety precautions you follow when working with quilting equipment and materials?

- Wearing appropriate safety gear (safety glasses, earplugs).

- Keeping long hair and loose clothing away from moving parts.

- Ensuring proper ventilation to prevent inhalation of dust or fumes.

- Storing sharp tools safely and discarding needles properly.

- Following manufacturer’s instructions for equipment operation.

7. How do you stay up-to-date with the latest quilting techniques and trends?

- Attending quilting workshops and classes.

- Reading quilting magazines and books.

- Joining quilting guilds and online communities.

- Following quilting influencers and designers on social media.

- Experimenting with new materials and techniques.

8. What are your strengths and weaknesses as a Quilter Fixer?

Strengths:

- Strong technical skills in quilting equipment repair and maintenance.

- In-depth knowledge of quilting techniques and fabrics.

- Attention to detail and precision in workmanship.

Weaknesses:

- Limited experience in specific advanced quilting techniques.

- Working under tight deadlines can sometimes lead to stress.

9. How do you prioritize tasks and manage your time while working on multiple projects?

- Using a to-do list or project management tool.

- Breaking down large projects into smaller, manageable tasks.

- Setting realistic deadlines for each task.

- Prioritizing tasks based on urgency and importance.

- Delegating tasks to others when necessary.

10. Why are you interested in joining our company as a Quilter Fixer?

I am drawn to your company’s reputation for excellence in the quilting industry. I believe that my skills and experience as a Quilter Fixer would be a valuable asset to your team. I am eager to contribute to your success and provide exceptional service to your customers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Quilter Fixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Quilter Fixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Quilter Fixer is responsible for maintaining and repairing quilting machines. They work closely with quilters to identify and resolve issues with the machines, ensuring that they are operating at peak efficiency. The key job responsibilities include:

1. Machine Maintenance

– Inspect and clean machines regularly to prevent breakdowns and extend their lifespan.

– Lubricate and adjust machines according to manufacturer’s specifications.

– Replace worn or damaged parts to maintain optimal machine performance.

2. Troubleshooting and Repair

– Diagnose and resolve mechanical and electrical issues with quilting machines.

– Repair or replace faulty components, such as motors, gears, and sensors.

– Test and calibrate machines to ensure they are operating properly after repairs.

3. Customer Support

– Provide technical support to quilters, answering their questions and addressing their concerns.

– Train quilters on proper machine operation and maintenance techniques.

– Collaborate with quilters to develop solutions to specific quilting challenges.

4. Safety Compliance

– Ensure that quilting machines are operated in accordance with safety regulations.

– Perform regular safety checks and inspections to identify potential hazards.

– Train quilters on proper safety procedures and equipment handling.

Interview Tips

Preparing for a Quilter Fixer interview requires a combination of technical knowledge and soft skills. Here are some tips and hacks to help you ace the interview:

1. Research the Company and Industry

– Learn about the company’s history, products, and services.

– Understand the current trends and challenges in the quilting industry.

2. Highlight Your Technical Skills

– Emphasize your expertise in quilting machine maintenance and repair.

– Provide examples of complex problems you have solved and repairs you have successfully executed.

3. Demonstrate Your Troubleshooting Abilities

– Describe your approach to troubleshooting quilting machine issues.

– Share examples of how you have identified and resolved problems in previous roles.

4. Show Your Customer Service Skills

– Highlight your ability to communicate effectively with quilters.

– Describe how you have resolved customer complaints and exceeded expectations.

5. Emphasize Your Safety Awareness

– Emphasize your understanding of quilting machine safety regulations.

– Share examples of your initiatives to promote safety in the workplace.

6. Prepare Questions for the Interviewer

– Ask thoughtful questions about the company, the position, and the industry.

– This shows your interest and engagement in the opportunity.

Next Step:

Now that you’re armed with the knowledge of Quilter Fixer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Quilter Fixer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini