Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Netting Weaver position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

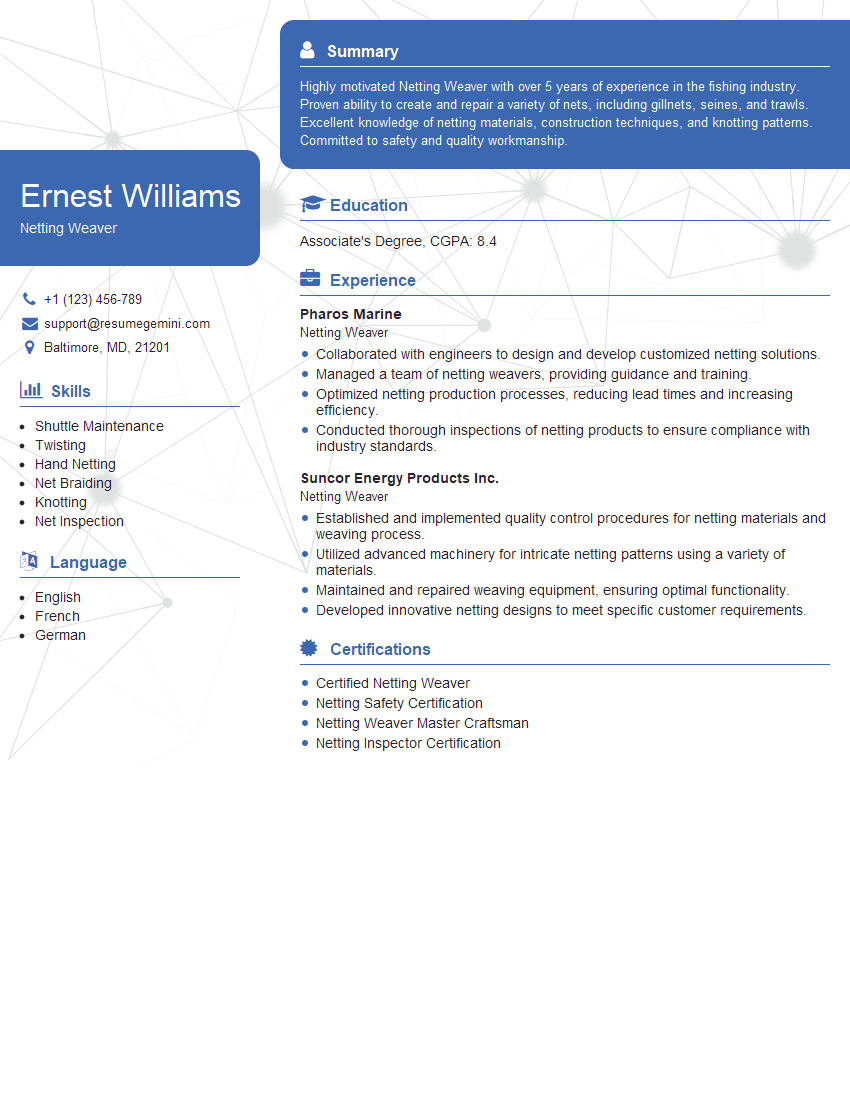

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Netting Weaver

1. What are the different types of netting machines and their uses?

Netting machines are classified based on their method of operation, size, and intended use. They can be categorized into various types:

- Shuttle netting machines: Automated machines that use shuttles to weave the netting. They are suitable for producing large-scale fishing nets and sports nets.

- Knotless netting machines: Advanced machines that produce knotless netting using a unique braiding process. They create nets with higher strength, reduced drag, and improved durability.

- Raschel knitting machines: Used to produce raschel lace, a type of knitted fabric with intricate openwork patterns. They are ideal for making decorative nets, veils, and lace garments.

- Chain-link fencing machines: Designed to produce continuous rolls of chain-link fencing. These machines weave metal wires into a diamond-shaped mesh pattern for security and perimeter fencing.

2. How do you ensure the quality and durability of the netting products?

Raw Material Selection:

- Selecting high-tenacity yarns, such as nylon or polyethylene, ensures the strength and longevity of the netting.

- Ensuring proper UV protection and chemical resistance to withstand harsh environmental conditions.

Production Process:

- Maintaining precise tension during weaving to prevent sagging or weakening of the net.

- Using advanced knotting or braiding techniques for secure and durable connections.

- Regular machine calibration and maintenance to minimize defects.

Quality Control Measures:

- Conducting thorough inspections throughout the production process to identify and rectify any imperfections.

- Performing tensile strength and durability tests to ensure the netting meets quality standards.

- Implementing quality assurance protocols to maintain consistency and reliability.

3. How do you optimize the efficiency of netting production?

- Machine optimization: Regular maintenance, upgrades, and operator training to maximize machine performance and minimize downtime.

- Raw material management: Efficient inventory management and procurement strategies to ensure timely availability of high-quality materials.

- Process improvement: Continuous analysis of production processes to identify bottlenecks and implement improvements for faster throughput.

- Automation: Adopting automated equipment and technologies to streamline production and reduce manual labor.

- Skilled workforce: Investing in training and upskilling employees to enhance their productivity and efficiency.

4. What factors influence the choice of netting materials and mesh size for different applications?

- Intended use: The purpose of the netting, such as fishing, sports, or protection, determines the required strength and durability.

- Target species: For fishing nets, the mesh size and material must match the target species’ size and behavior.

- environmental conditions: The netting must be resistant to UV radiation, moisture, and chemicals present in the application environment.

- Regulations: Compliance with industry standards and government regulations regarding mesh size and material specifications.

- Cost and availability: Considering the material and production costs, as well as the availability of the desired netting materials.

5. How do you troubleshoot common netting machine problems and minimize downtime?

- Mechanical issues: Identifying and repairing mechanical faults, such as broken needles or tension problems, promptly.

- Electrical problems: Diagnosing and resolving electrical issues, such as faulty wiring or component failures, to restore machine functionality.

- Yarn quality issues: Monitoring yarn quality and making adjustments to prevent yarn breakage or uneven netting.

- Software errors: Troubleshoot software-related problems, such as incorrect settings or program errors, to ensure smooth machine operation.

- Preventive maintenance: Implementing a regular maintenance schedule to identify and address potential issues before they cause downtime.

6. How do you ensure the safety of operators working with netting machines?

- Machine guarding: Equipping machines with proper guards and safety measures to prevent accidents and injuries.

- Operator training: Providing comprehensive safety training to operators on machine operation, hazard identification, and emergency procedures.

- Personal protective equipment (PPE): Enforcing the use of appropriate PPE, such as gloves, safety glasses, and earplugs, to protect operators from potential hazards.

- Risk assessment: Conducting regular risk assessments to identify and mitigate potential safety hazards in the work environment.

- Emergency preparedness: Establishing clear emergency protocols and ensuring that all operators are aware of them.

7. What are the latest advancements in netting technology and how are they impacting the industry?

- Advanced materials: Development of new materials with enhanced strength, durability, and UV resistance, leading to improved netting performance.

- Automated netting machines: Introduction of automated machines with advanced features, such as self-diagnosing capabilities and remote monitoring, increasing production efficiency.

- Smart netting: Integration of sensors and IoT technologies into netting systems, enabling real-time monitoring and data collection for optimizing performance and safety.

- Eco-friendly netting: Focus on developing environmentally sustainable netting materials and production processes to reduce the industry’s environmental footprint.

- Nanotechnology: Exploration of nanotechnology applications in netting to enhance durability, water repellency, and antimicrobial properties.

8. How do you stay updated with the latest trends and innovations in the netting industry?

- Industry events and conferences: Attending trade shows and conferences to connect with industry professionals and learn about emerging technologies.

- Technical publications and research: Reading industry journals, research papers, and technical articles to stay informed about advancements in netting materials and manufacturing processes.

- Online resources and webinars: Utilizing online platforms and webinars to access up-to-date information and participate in industry discussions.

- Networking with industry experts: Building relationships with netting manufacturers, researchers, and industry experts to exchange knowledge and insights.

- Continuing education: Pursuing additional education or certifications related to netting technology to enhance expertise and stay competitive.

9. What is your approach to managing a team of netting weavers and ensuring their productivity?

- Clear communication: Establishing open and effective communication channels to provide clear instructions, expectations, and support.

- Performance monitoring: Regularly assessing team performance, identifying strengths and areas for improvement, and providing constructive feedback.

- Skill development: Investing in training and development opportunities for team members to enhance their skills, knowledge, and productivity.

- Motivation and recognition: Recognizing and rewarding team members for their contributions, fostering a positive and motivated work environment.

- Empowerment: Empowering team members to make decisions and take ownership of their work, promoting accountability and initiative.

10. How do you ensure customer satisfaction and build strong customer relationships?

- Understanding customer needs: Actively listening to customer requirements and tailoring products and services to meet their specific needs.

- Responsive communication: Promptly addressing customer inquiries, providing timely updates, and maintaining open communication throughout the business relationship.

- Quality products and services: Delivering high-quality netting products and services that consistently meet or exceed customer expectations.

- Proactive problem-solving: Anticipating potential issues and proactively addressing them to minimize disruptions and maintain customer trust.

- Building trust: Establishing long-term relationships based on trust, reliability, and open communication.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Netting Weaver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Netting Weaver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Netting Weaver is responsible for operating industrial machinery to create nets for various purposes such as fishing, sports, and industrial applications. Their primary duties involve setting up, operating, and maintaining the machinery while ensuring the nets meet the desired specifications.

1. Machine Operation and Maintenance

Setting up, calibrating, and operating netting machines according to production schedules and specifications.

- Monitoring machine performance and making adjustments as needed to optimize efficiency and quality.

- Performing regular maintenance, cleaning, and lubrication to ensure the smooth operation of the machinery.

2. Net Production

Weaving nets using various materials such as nylon, polyester, or polyethylene.

- Selecting the appropriate materials and settings based on the desired mesh size, strength, and durability.

- Inspecting nets throughout the production process to ensure they meet quality standards.

3. Quality Control

Conducting quality checks on the finished nets to ensure they meet specifications.

- Measuring mesh size, knot strength, and overall dimensions according to established standards.

- Identifying any defects or non-conformities and taking corrective action.

4. Safety and Compliance

Adhering to all relevant safety regulations and guidelines.

- Using proper personal protective equipment and following established safety procedures.

- Maintaining a clean and organized work area to prevent accidents.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips and tricks to help you ace the interview for a Netting Weaver position:

1. Research the Company and Position

Take the time to research the company you’re applying to and the specific role you’re interested in. This will give you a better understanding of the company’s culture, values, and the job requirements.

- Visit the company’s website, read their mission statement, and check out their social media profiles.

- Review the job description carefully and note the key skills and experience required for the position.

2. Highlight Relevant Skills and Experience

When answering interview questions, focus on highlighting the skills and experience that are most relevant to the Netting Weaver role. Use specific examples to demonstrate your abilities.

- Emphasize your experience in operating netting machinery, adjusting settings, and maintaining equipment.

- Provide examples of how you have ensured the quality of nets through inspections and testing.

3. Show Enthusiasm and Passion

Let the interviewer know that you are genuinely interested in the position and the company. Express your enthusiasm for working in the netting industry and your passion for creating high-quality nets.

- Share any personal experiences or projects that demonstrate your interest in netting or related fields.

- Ask thoughtful questions during the interview to show your engagement and eagerness to learn more about the role.

4. Prepare for Common Interview Questions

Research and prepare for common interview questions that you may encounter. Practice your answers to these questions in advance.

- Tell me about your experience in operating netting machinery.

- How do you ensure the quality of the nets you produce?

- What is your experience in troubleshooting and resolving issues with netting machinery?

5. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally for the interview. Arrive on time to show your respect for the interviewer and the company.

- Wear clean and pressed clothing that is appropriate for an office setting.

- Plan your route in advance to ensure you have plenty of time to get to the interview location.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Netting Weaver interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!