Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Threading Machine Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

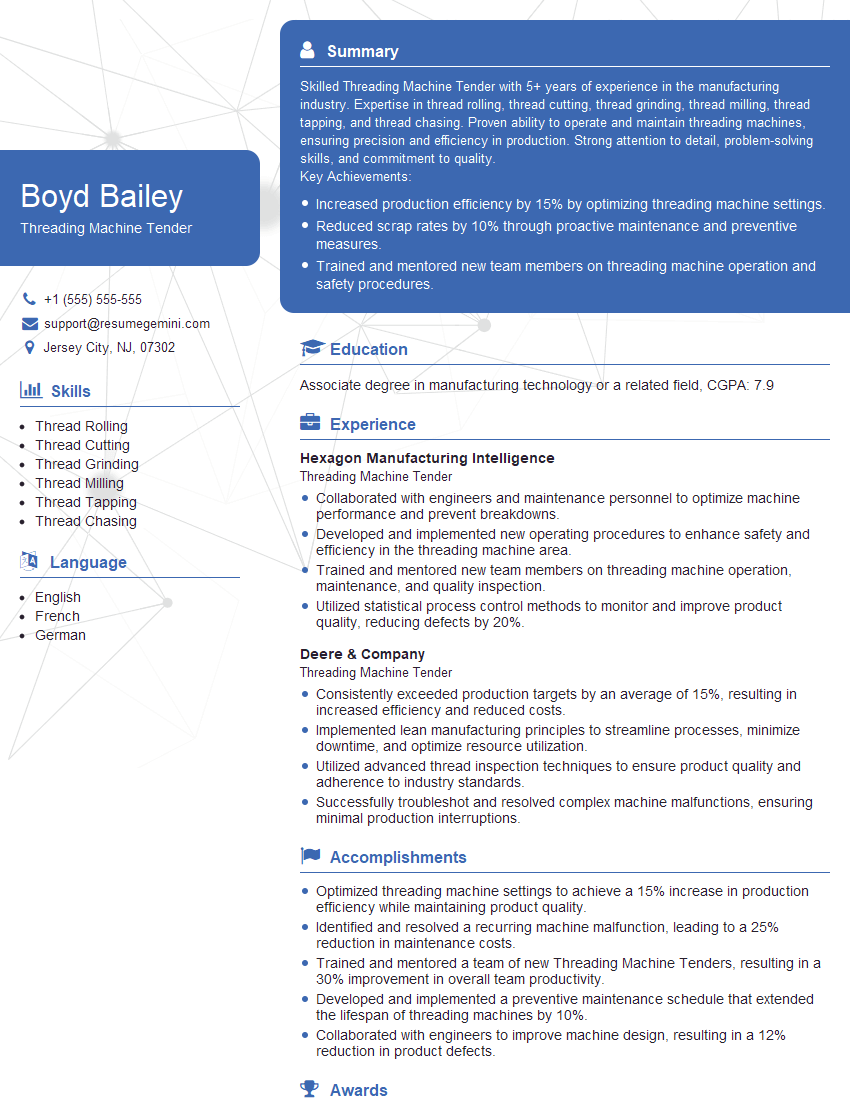

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Threading Machine Tender

1. Explain the basic operation of a threading machine.

- Threading machines cut threads onto the outside surface of a workpiece.

- The machine uses a rotating cutter to cut the threads into the workpiece.

- The cutter is fed into the workpiece at a controlled rate, and the workpiece is rotated as the cutter cuts the threads.

2. What are the different types of threading machines?

- There are two main types of threading machines: manual and CNC.

- Manual threading machines are operated by hand, while CNC threading machines are controlled by a computer.

3. What are the different types of threads that can be cut on a threading machine?

- There are many different types of threads that can be cut on a threading machine, including:

- V-threads

- Square threads

- Buttress threads

- Acme threads

4. What are the factors that affect the quality of a threaded surface?

- The quality of a threaded surface is affected by a number of factors, including:

- The type of thread being cut

- The material of the workpiece

- The condition of the cutting tool

- The cutting speed and feed rate

5. What are the safety precautions that should be taken when operating a threading machine?

- There are a number of safety precautions that should be taken when operating a threading machine, including:

- Wearing proper safety gear, including safety glasses, gloves, and a lab coat

- Keeping the machine area clean and free of debris

- Being aware of the machine’s moving parts and keeping clear of them

- Never operating the machine while under the influence of drugs or alcohol

6. What are the maintenance procedures that should be performed on a threading machine?

- There are a number of maintenance procedures that should be performed on a threading machine, including:

- Regularly cleaning the machine

- Lubricating the moving parts

- Inspecting the cutting tool for wear and tear

- Checking the machine’s alignment

7. What are the troubleshooting procedures for a threading machine?

- There are a number of troubleshooting procedures for a threading machine, including:

- Checking the machine for any loose or damaged parts

- Checking the cutting tool for wear and tear

- Adjusting the machine’s settings

- Contacting a qualified technician

8. What are the applications of threading machines?

- Threading machines are used in a variety of applications, including:

- Manufacturing

- Construction

- Automotive repair

- Aerospace

9. What are the advantages of using a threading machine?

- There are a number of advantages to using a threading machine, including:

- Speed

- Accuracy

- Consistency

- Versatility

10. What are the disadvantages of using a threading machine?

- There are a few disadvantages to using a threading machine, including:

- Cost

- Complexity

- Maintenance

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Threading Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Threading Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Threading Machine Tender operates and maintains threading machines, which create threads on metal components. They are expected to ensure that the machines are running smoothly and efficiently by carrying out routine maintenance and adjustments.

1. Operating Threading Machines

The primary task of a Threading Machine Tender is to operate threading machines. This involves loading and unloading workpieces, setting up and adjusting the machine for each job, and monitoring the machine during operation.

- Load and unload workpieces from the threading machine.

- Set up and adjust the machine for each job, including selecting the correct threading tool and setting the cutting speed and feed rate.

- Monitor the machine during operation and make adjustments as needed to ensure that the threads are being cut correctly.

2. Maintaining Threading Machines

In addition to operating the machines, Threading Machine Tenders are also responsible for maintaining them. This includes cleaning and lubricating the machines, as well as performing minor repairs and adjustments.

- Clean and lubricate the machines on a regular basis.

- Perform minor repairs and adjustments to the machines, such as replacing worn parts and adjusting belts.

- Inspect the machines regularly for signs of wear or damage.

3. Quality Control

Threading Machine Tenders are also responsible for ensuring that the threads they are cutting meet the required specifications. This involves inspecting the threads for defects and measuring them to ensure that they are the correct size and pitch.

- Inspect the threads for defects, such as burrs, nicks, and scratches.

- Measure the threads to ensure that they are the correct size and pitch.

- Reject any workpieces that do not meet the required specifications.

4. Other Duties

In addition to the above, Threading Machine Tenders may also be responsible for:

- Assisting with the setup and operation of other machines.

- Maintaining a clean and organized work area.

- Following safety procedures and regulations.

Interview Tips

Preparing for an interview can be daunting, but there are some things you can do to increase your chances of success. Here are a few tips:

1. Research the Company and the Position

Before the interview, take some time to learn about the company and the position you are applying for. This will help you understand the company’s culture and what they are looking for in a candidate.

- Visit the company’s website.

- Read articles about the company in the news.

- Talk to people who work at the company.

2. Practice Answering Common Interview Questions

There are some common interview questions that you are likely to be asked. Take some time to practice answering these questions so that you can deliver your answers confidently and concisely.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Dress Appropriately

First impressions matter, so make sure you dress appropriately for the interview. This means wearing clean, pressed clothes that are suitable for a professional setting.

- Wear a suit or dress pants and a button-down shirt or blouse.

- Make sure your clothes are clean and pressed.

- Avoid wearing too much jewelry or perfume.

4. Be Punctual

Punctuality shows that you are respectful of the interviewer’s time. Arrive for your interview on time, or even a few minutes early.

- Give yourself plenty of time to get to the interview location.

- If you are running late, call the interviewer and let them know.

- Don’t be afraid to ask for directions if you get lost.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Threading Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!