Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Automatic Beam Warper Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Automatic Beam Warper Tender so you can tailor your answers to impress potential employers.

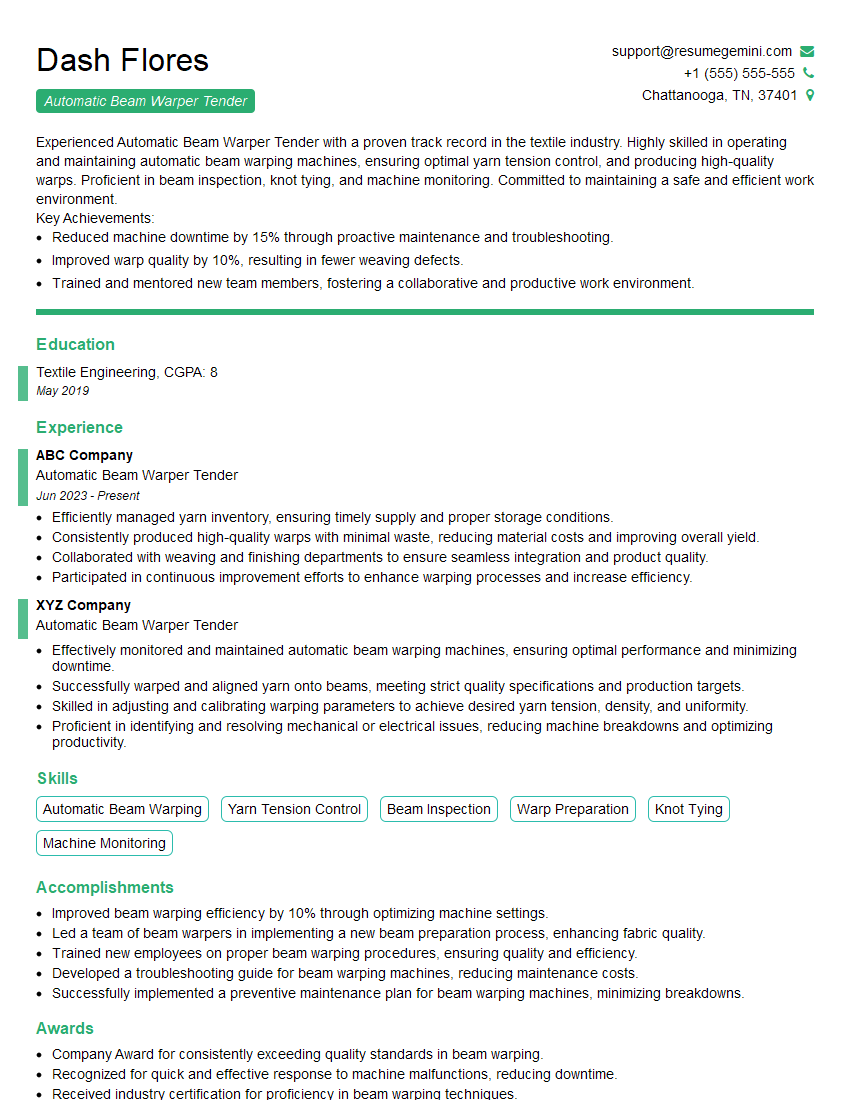

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Beam Warper Tender

1. Explain the role of the warp beam and its importance in the weaving process?

The warp beam is a cylindrical device that holds the warp threads in the weaving process. It plays a crucial role in supplying a continuous supply of warp threads to the loom during weaving. Without a properly prepared warp beam, the weaving process would not be possible.

2. Describe the process of warping on an automatic beam warper.

Beam Preparation

- Mount the empty beam on the warper.

- Create a creel to hold the yarn cones.

- Thread the yarn ends through the tensioners and guides.

Warping Process

- Start the warper to wind the yarn onto the beam.

- Monitor the tension and alignment of the yarn.

- Detect and correct any yarn breaks or irregularities.

3. How do you ensure the proper tension of the warp yarns during beaming?

Ensuring proper warp yarn tension is critical to prevent yarn breakage and irregularities in the woven fabric. Automatic beam warpers typically use tensioners with adjustable settings to control the tension of each yarn.

- Calibrate the tensioners according to the yarn type and desired fabric characteristics.

- Monitor the tension throughout the warping process and make adjustments as needed.

- Use tension monitoring devices to ensure consistent tension across the warp beam.

4. What are the common defects that can occur during beaming, and how do you prevent or correct them?

Common defects during beaming include:

- Yarn breaks: Caused by excessive tension, improper threading, or yarn damage. Prevent by properly setting tension, inspecting yarn, and using anti-static devices.

- Yarn entanglement: Caused by incorrect guiding or yarn slippage. Prevent by ensuring proper yarn path and using anti-tangle devices.

- Cross-overs: Caused by yarn skipping over other yarns. Prevent by adjusting tension and using yarn separators.

5. Explain the importance of beam doffing and how it affects the weaving process.

Beam doffing is the process of removing the completed warp beam from the warper. It is essential because:

- Yarn continuity: Ensures a continuous supply of warp yarn for weaving.

- Beam stability: Proper doffing prevents damage to the beam or yarn.

- Warp quality: Avoids yarn tangles or breaks during the doffing process.

6. Describe the safety precautions to be observed while operating an automatic beam warper.

- Wear proper safety gear, including goggles and gloves.

- Keep the work area clean and free from tripping hazards.

- Inspect the machine regularly for any damage or loose parts.

- Never operate the warper with guards or covers removed.

- Be aware of the moving parts and avoid getting entangled.

7. Explain the role of sensors in the automatic beam warper and how they ensure efficient operation.

Sensors play a vital role in the efficient operation of automatic beam warpers:

- Yarn break sensors: Detect broken yarns and stop the machine to prevent further damage.

- Tension sensors: Monitor yarn tension and adjust it as needed to maintain consistent quality.

- Beam diameter sensors: Measure the diameter of the warp beam and control the winding process accordingly.

8. Describe the process of calibrating an automatic beam warper.

Calibrating an automatic beam warper involves:

- Tension calibration: Setting the yarn tension to the desired level using calibrated weights or tension gauges.

- Length calibration: Adjusting the warper to wind the correct length of yarn onto the beam.

- Diameter calibration: Ensuring the beam diameter meets specifications using measuring tools or sensors.

9. Explain the importance of preventive maintenance for an automatic beam warper and describe the key tasks involved.

Preventive maintenance is crucial to ensure the longevity and optimal performance of an automatic beam warper. Key tasks include:

- Regular cleaning: Removing dust, debris, and yarn residue.

- Lubrication: Applying lubricants to moving parts to reduce friction and wear.

- Inspection: Checking for any damage or loose parts and tightening or replacing as needed.

- Sensor testing: Ensuring that sensors are functioning correctly to prevent malfunctions.

10. Describe the process of troubleshooting common problems encountered with automatic beam warpers.

Common problems and troubleshooting steps:

- Yarn breakage: Check tension settings, yarn quality, and sensors.

- Uneven winding: Adjust tension, check beam diameter sensor, and inspect for any obstruction.

- Machine stoppage: Inspect for yarn breaks, sensor malfunctions, or mechanical issues.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Beam Warper Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Beam Warper Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Automatic Beam Warper Tender is responsible for operating and maintaining automatic beam warping machines, which are used to prepare warp beams for weaving. Key responsibilities include:

1. Preparing Warp Beams

Setting up and adjusting the warping machine, including selecting the appropriate yarn and tension settings.

2. Analyzing Yarn Quality

Inspecting yarn for defects and ensuring that it meets quality standards.

3. Monitoring Machine Operation

Monitoring the warping process to ensure that it is running smoothly and efficiently.

4. Identifying and Troubleshooting Issues

Identifying and resolving any issues that arise during the warping process.

5. Maintaining Equipment

Performing regular maintenance and cleaning of the warping machine to ensure its optimal performance.

Interview Tips

To ace your interview for an Automatic Beam Warper Tender position, it is crucial to prepare thoroughly. Here are some tips to help you make a strong impression:

1. Research the Company and Industry

Demonstrate your interest in the company and the textile industry by researching their website, news articles, and industry trends.

2. Highlight Relevant Skills and Experience

Emphasize your experience with automatic beam warping machines, yarn analysis, and equipment maintenance. Quantify your accomplishments whenever possible.

3. Practice Common Interview Questions

Prepare for common interview questions related to your technical skills, problem-solving abilities, and work ethic.

4. Ask Informed Questions

Show your interest and engagement by asking thoughtful questions about the company, the role, and the industry.

5. Dress Professionally and Arrive on Time

Make a positive first impression by dressing appropriately and arriving punctually for your interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Automatic Beam Warper Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!