Are you gearing up for an interview for a Bandage Winding Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Bandage Winding Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

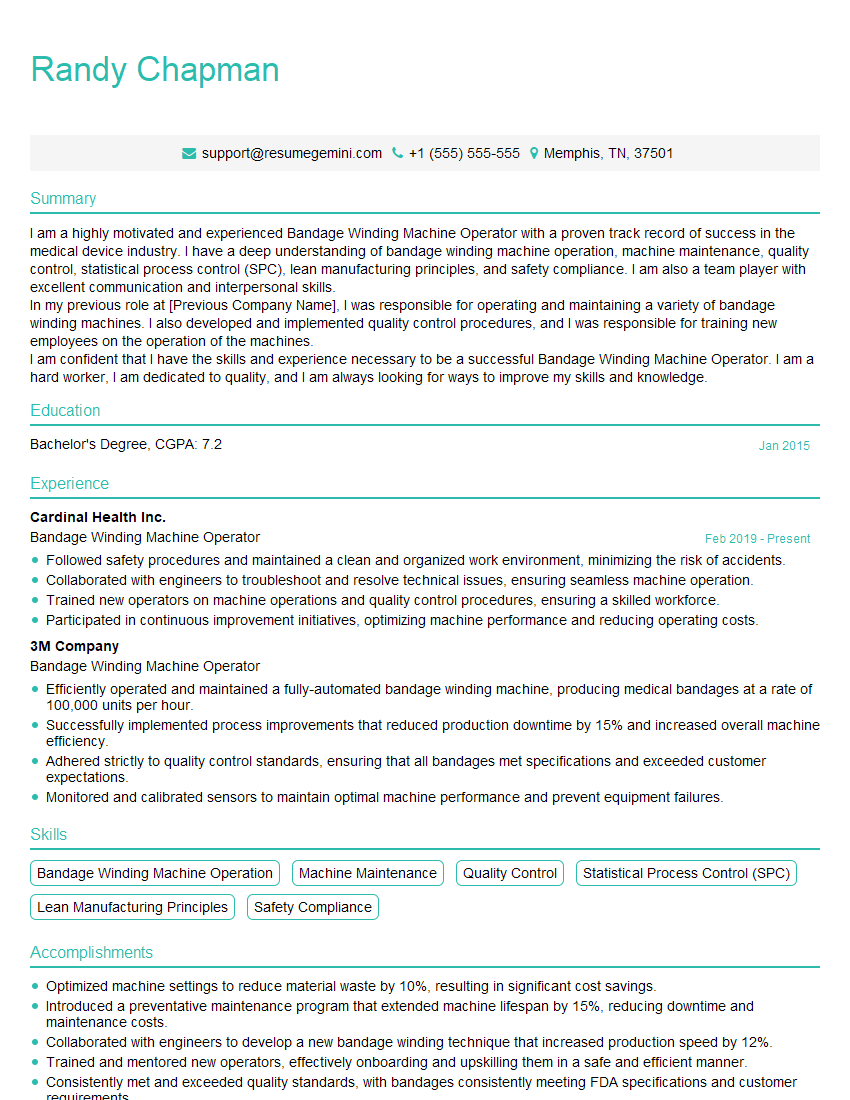

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bandage Winding Machine Operator

1. Describe the process of setting up a bandage winding machine.

- Inspect the machine for any damage or issues.

- Load the core onto the winding spindle.

- Thread the bandage material onto the machine.

- Set the winding tension and speed.

- Calibrate the machine to ensure the bandages are wound to the correct specifications.

2. How do you ensure the quality of the bandages produced by the winding machine?

Quality checks

- Visual inspection for defects such as breaks or tears.

- Measure the width and thickness of the bandages.

- Check the tensile strength of the bandages.

Preventive maintenance

- Regularly clean and lubricate the machine.

- Inspect and replace worn parts as needed.

- Monitor the machine’s performance to identify potential issues.

3. What troubleshooting steps would you take if the bandage winding machine malfunctions?

- Identify the symptoms of the malfunction.

- Refer to the machine’s manual for possible causes.

- Check for loose connections or damaged parts.

- Reset the machine if necessary.

- Contact a qualified technician if the problem cannot be resolved.

4. How do you maintain the efficiency of the bandage winding machine?

- Monitor the machine’s performance and identify areas for improvement.

- Adjust the winding tension and speed to optimize production.

- Minimize downtime by scheduling regular maintenance and repairs.

- Train operators on proper machine operation and maintenance techniques.

- Use quality materials to reduce the risk of machine malfunctions.

5. Describe the safety precautions that must be taken when operating a bandage winding machine.

- Wear appropriate personal protective equipment (PPE), such as gloves and safety glasses.

- Keep long hair and loose clothing away from moving parts.

- Do not operate the machine when it is not properly guarded.

- Be aware of the machine’s operating temperature and keep it well-ventilated.

- Follow all manufacturer’s instructions and safety guidelines.

6. What is the maintenance schedule for a bandage winding machine?

- Daily: Clean and lubricate the machine.

- Weekly: Inspect the machine for loose connections or damaged parts.

- Monthly: Calibrate the machine to ensure accuracy.

- Quarterly: Perform a thorough inspection and replace any worn parts.

- Annually: Schedule a professional maintenance check-up.

7. How do you adjust the winding tension on a bandage winding machine?

- Locate the tension adjustment knob or dial.

- Turn the knob or dial in the desired direction to increase or decrease the tension.

- Refer to the machine’s manual for specific instructions.

- Test the tension by winding a small sample of bandage material.

- Make further adjustments as needed.

8. What are the different types of bandages that can be produced on a bandage winding machine?

- Elastic bandages

- Non-elastic bandages

- Adhesive bandages

- Gauze bandages

- Crepe bandages

9. How do you calculate the production capacity of a bandage winding machine?

- Determine the machine’s winding speed.

- Consider the width and thickness of the bandages being produced.

- Calculate the running time of the machine.

- Factor in any downtime for maintenance or changeovers.

- Use the formula: Production Capacity = Winding Speed x Running Time x Efficiency

10. What are the common challenges faced by bandage winding machine operators?

- Maintaining consistent bandage quality

- Preventing machine malfunctions and downtime

- Meeting production targets

- Ensuring operator safety

- Keeping up with technological advancements

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bandage Winding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bandage Winding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bandage Winding Machine Operators play a crucial role in the manufacturing of bandages, ensuring the efficient and precise production of medical dressings. Their primary responsibilities include:

1. Machine Operation

Operate and monitor bandage winding machines to produce bandages according to specified dimensions, materials, and quality standards.

- Set up machines, load materials, and adjust settings to achieve desired output.

- Monitor machines during operation, ensuring smooth functioning and preventing breakdowns.

- Troubleshoot and resolve machine malfunctions promptly.

2. Quality Control

Inspect bandages produced by the machine to ensure they meet quality specifications.

- Check bandages for defects, such as tears, wrinkles, or uneven winding.

- Conduct routine quality checks to maintain consistent product quality.

- Document any quality issues and report them to supervisors.

3. Maintenance and Cleaning

Maintain and clean bandage winding machines to ensure optimal performance.

- Perform routine maintenance tasks, such as lubrication, cleaning, and filter replacements.

- Identify and address potential maintenance issues before they escalate into major breakdowns.

- Keep work area clean and organized to maintain a safe and efficient work environment.

4. Production Efficiency

Monitor production processes to identify areas for improvement and enhance efficiency.

- Analyze production data to identify bottlenecks and suggest solutions.

- Implement process improvements to increase productivity and reduce costs.

- Collaborate with other departments to optimize production processes.

Interview Tips

To ace the interview for a Bandage Winding Machine Operator position, it is essential to prepare thoroughly and showcase your relevant skills and experience. Here are some tips to help you impress the hiring managers:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and industry position.

- Visit the company website and social media pages.

- Read industry publications and news articles.

- Research the specific job description to understand the company’s expectations.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that directly relate to the key job responsibilities.

- Quantify your accomplishments whenever possible, using specific metrics and results.

- Prepare examples of your work that demonstrate your ability to operate and maintain bandage winding machines.

- Highlight your understanding of quality control procedures and your commitment to maintaining high standards.

3. Be Prepared to Explain Your Motivation

Explain why you are interested in the position and how your skills and experience make you a suitable candidate.

- Research the healthcare industry and the importance of bandage manufacturing.

- Express your passion for contributing to the production of medical products that help patients.

- Highlight your interest in working in a manufacturing environment.

4. Practice Your Answers

Prepare for common interview questions and practice your responses.

- Ask family or friends to conduct mock interviews.

- Record yourself practicing and analyze your strengths and weaknesses.

- Develop clear and concise answers that showcase your skills and experience.

5. Professionalism and Enthusiasm

Dress professionally and arrive for the interview on time.

- Maintain eye contact, speak clearly, and demonstrate a positive attitude.

- Ask thoughtful questions to show your interest in the position and the company.

- Thank the interviewer for their time and send a follow-up email.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bandage Winding Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!