Are you gearing up for an interview for a Ball Fringe Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Ball Fringe Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

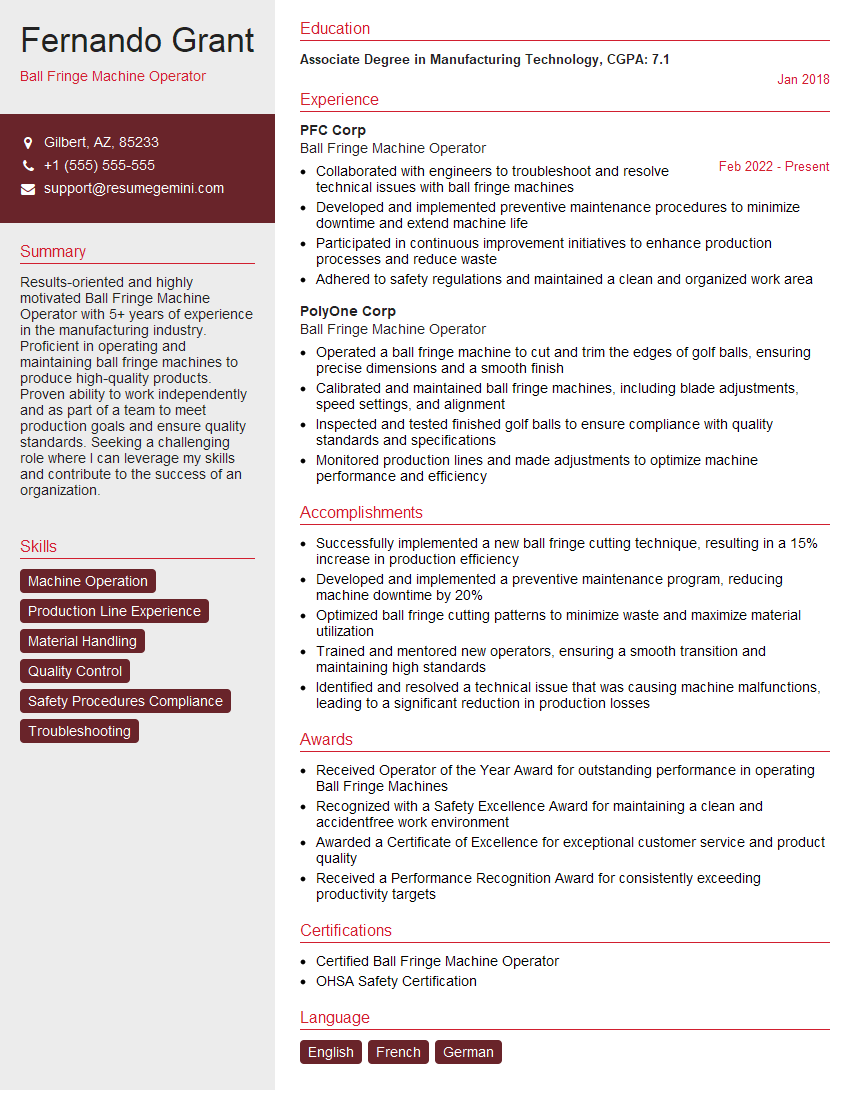

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ball Fringe Machine Operator

1. What are the key responsibilities of a Ball Fringe Machine Operator?

The key responsibilities of a Ball Fringe Machine Operator include:

- Operating and maintaining a ball fringe machine to produce high-quality ball fringes

- Setting up and adjusting the machine to meet customer specifications

- Inspecting and measuring the finished product to ensure quality standards are met

- Maintaining a clean and safe work area

- Following all safety procedures and regulations

2. What are the different types of ball fringe machines?

Types of Ball Fringe Machines

- Manual Ball Fringe Machine

- Semi-Automatic Ball Fringe Machine

- Fully-Automatic Ball Fringe Machine

Working Process

- The fringe machine trims the edges of golf balls, creating a consistent and even fringe around the ball.

- The machine uses a rotating blade to cut the fringe, and the operator controls the depth and width of the cut.

- The finished product is a golf ball with a clean, precise fringe that meets the specifications of the customer.

3. What are the safety precautions that must be taken when operating a ball fringe machine?

When operating a ball fringe machine, it is important to take the following safety precautions:

- Wear appropriate safety gear, including eye protection, ear protection, and gloves

- Keep hands and fingers away from the rotating blade

- Never operate the machine when it is not properly guarded

- Follow all manufacturer’s instructions for safe operation

4. How do you troubleshoot common problems with a ball fringe machine?

Some common problems with ball fringe machines include:

- The machine is not cutting the fringe properly

- The machine is making excessive noise

- The machine is vibrating excessively

To troubleshoot these problems, you can:

- Check the blade for sharpness and replace it if necessary

- Tighten any loose bolts or screws

- Lubricate the machine according to the manufacturer’s instructions

- Check the machine’s alignment and adjust it if necessary

5. What are the different types of materials used to make ball fringes?

The different types of materials used to make ball fringes include:

- Nylon

- Polyester

- Cotton

- Silk

- Wool

Each type of material has its own unique properties, so it is important to choose the right material for the desired application.

6. What are the different types of finishes that can be applied to ball fringes?

The different types of finishes that can be applied to ball fringes include:

- Matte

- Glossy

- Satin

- Metallic

- Pearlescent

The type of finish will depend on the desired look and feel of the ball fringe.

7. What are the different sizes and shapes of ball fringes?

Ball fringes come in a variety of sizes and shapes, including:

- Round

- Oval

- Square

- Rectangular

- Custom shapes

The size and shape of the ball fringe will depend on the desired look and feel of the ball.

8. What is the difference between a ball fringe and a ball tassel?

A ball fringe is a decorative trim that is applied to the edge of a golf ball. A ball tassel is a decorative tassel that is attached to the end of a golf ball.

Ball fringes are typically made from nylon or polyester, while ball tassels are typically made from silk or wool.

9. What is the history of ball fringes?

Ball fringes have been used for centuries to decorate golf balls. The first ball fringes were made from leather or fabric, and they were often used to identify the owner of the ball.

Today, ball fringes are made from a variety of materials, and they are used for both decorative and functional purposes.

10. What are the latest trends in ball fringes?

The latest trends in ball fringes include:

- Use of new materials, such as metallic and pearlescent fabrics

- Use of custom shapes and sizes

- Use of multiple colors and textures

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ball Fringe Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ball Fringe Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ball Fringe Machine Operators play a crucial role in the production of golf balls, ensuring the precise cutting and finishing of ball fringes. Their key responsibilities encompass:

1. Ball Fringe Cutting

Operate ball fringe machines to precisely cut and shape the fringe of golf balls.

- Adjust machine settings to meet specific ball fringe specifications.

- Monitor cutting process and make necessary adjustments to ensure quality and accuracy.

2. Machine Maintenance and Repair

Perform routine maintenance and minor repairs on ball fringe machines.

- Lubricate and clean machine components to prevent wear and tear.

- Troubleshoot and resolve machine malfunctions, ensuring optimal performance.

3. Quality Control

Inspect and assess the quality of cut ball fringes, ensuring they meet established standards.

- Use measuring tools and gauges to verify fringe dimensions.

- Identify and correct any defects or inconsistencies in the cutting process.

4. Production Monitoring

Monitor production rates and identify areas for improvement.

- Track machine performance and identify bottlenecks that impact production efficiency.

- Suggest and implement process enhancements to increase productivity.

Interview Tips

To ace the interview for a Ball Fringe Machine Operator position, it’s essential to prepare thoroughly. Here are some tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, mission, and golf ball production processes. Understanding the industry trends and technological advancements in ball fringe cutting is also beneficial.

2. Emphasize Relevant Skills and Experience

Highlight your proficiency in operating ball fringe machines and relevant experience in machine maintenance. Quantify your accomplishments to demonstrate your impact on production efficiency and quality.

3. Prepare for Technical Questions

Be prepared to discuss your knowledge of ball fringe cutting techniques, machine settings, and troubleshooting procedures. It’s helpful to have a basic understanding of cutting tools and mechanical components.

4. Demonstrate Attention to Detail

Emphasize your ability to inspect and assess ball fringe quality meticulously. Explain how you ensure accuracy and consistency in the cutting process, ensuring the production of high-quality golf balls.

5. Ask Informed Questions

Prepare thoughtful questions that demonstrate your interest in the role and the company. This shows that you’re engaged and eager to learn more about the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ball Fringe Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!