Feeling lost in a sea of interview questions? Landed that dream interview for Cloth Winder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cloth Winder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

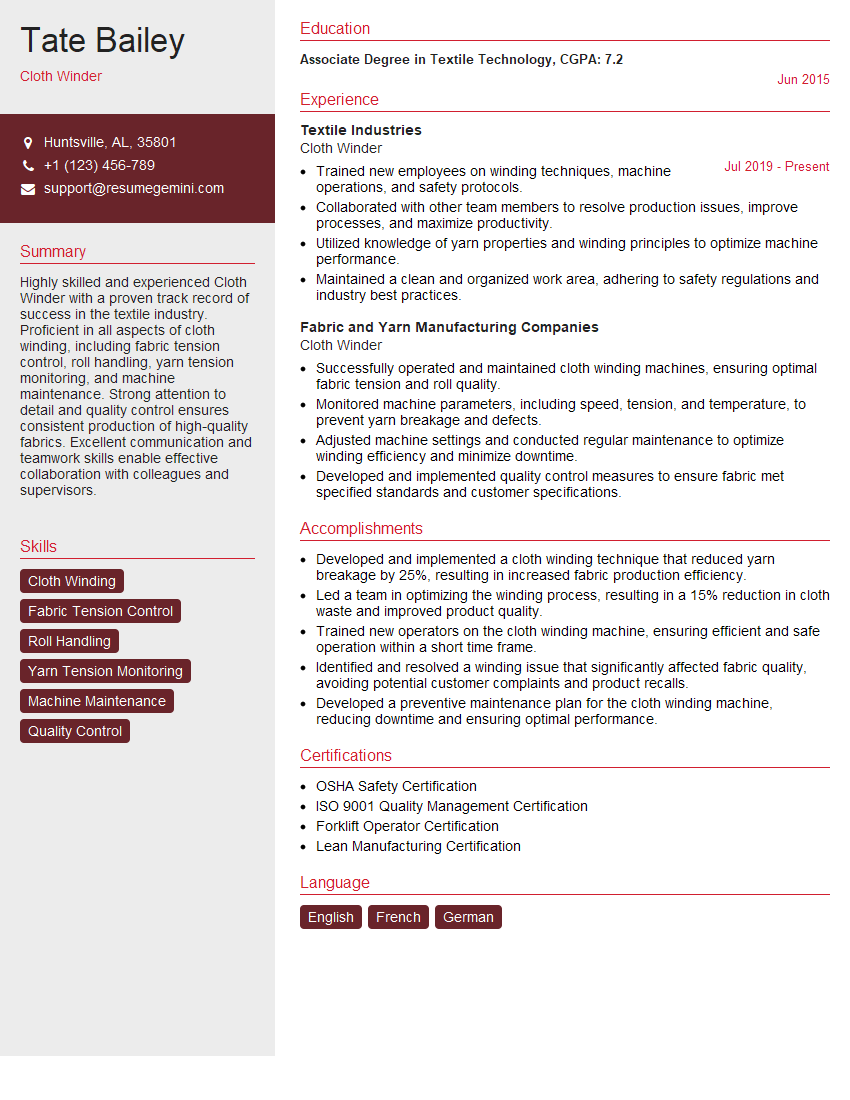

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cloth Winder

1. What are the different types of winding machines used in the industry?

- Warp winding machines

- Wef winding machines

- Yarn winding machines

- Fabric winding machines

2. What are the key factors to consider when selecting a winding machine?

Production rate

- The desired production rate will determine the type and size of winding machine required.

Yarn type

- The type of yarn being wound will also affect the choice of winding machine.

- For example, warp yarns require a different type of winding machine than weft yarns.

Package size

- The size of the package being wound will also affect the choice of winding machine.

- For example, large packages require a different type of winding machine than small packages.

Cost

- The cost of the winding machine is also an important factor to consider.

- The cost of the machine will depend on the type, size, and features of the machine.

3. What are the different types of winding defects?

- Yarn breaks

- Yarn knots

- Yarn slubs

- Yarn unevenness

- Package defects

4. What are the causes of winding defects?

- Yarn quality

- Winding machine settings

- Operator error

- Environmental conditions

5. How can winding defects be prevented?

- Use high-quality yarn

- Set the winding machine correctly

- Train operators properly

- Control the environmental conditions

6. What are the different types of winding machine maintenance?

Preventive maintenance

- Regular cleaning and lubrication of the machine

- Inspection of the machine for wear and tear

- Replacement of worn parts

Corrective maintenance

- Repairing or replacing damaged parts

- Adjusting the machine to correct defects

7. How can winding machine maintenance costs be reduced?

- Implementing a preventive maintenance program

- Training operators on proper maintenance procedures

- Using high-quality parts

- Keeping a spare parts inventory

8. What are the different types of winding machine safety hazards?

- Moving parts

- Electrical hazards

- Yarn hazards

- Noise hazards

9. How can winding machine safety hazards be prevented?

- Guarding moving parts

- Insulating electrical components

- Controlling yarn hazards

- Reducing noise levels

10. What are the different types of winding machine automation?

Manual winding

- The operator manually controls the winding process.

Semi-automatic winding

- The operator loads the yarn onto the machine and the machine winds the yarn automatically.

Fully automatic winding

- The machine automatically loads the yarn, winds the yarn, and unloads the finished package.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cloth Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cloth Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The role of a Cloth Winder covers a full spectrum of duties, all centered around the efficient operation of winding equipment and ensuring the production of high-quality textile products. These duties encompass:

1. Equipment Setup and Operation

Preparing and configuring winding machines according to established work orders, ensuring optimal performance and product quality. Responsibilities include:

- Selecting and installing appropriate winding heads and accessories based on fabric specifications.

- Adjusting machine parameters such as speed, tension, and traverse rate to achieve desired winding patterns and fabric properties.

2. Fabric Loading and Monitoring

Inspecting fabric rolls for defects before mounting them on the winder. This includes:

- Identifying and removing any irregularities or flaws that could affect winding efficiency or product quality.

- Calculating and adjusting the tension of fabric as it is wound onto the spool or roll.

3. Quality Control and Inspection

Maintaining vigilance over the winding process to ensure that the final product meets established quality standards. This involves:

- Monitoring the tightness, evenness, and consistency of the wound fabric.

- Identifying and correcting any defects or irregularities that may arise during the winding process.

4. Production Optimization

Evaluating winding efficiency and identifying areas for improvement. Responsibilities include:

- Analyzing production data to identify bottlenecks and inefficiencies in the winding process.

- Implementing process improvements to reduce downtime, minimize waste, and increase overall productivity.

Interview Tips

To make a lasting impression during your interview for a Cloth Winder position, consider the following tips:

1. Research the Company and Industry

Demonstrate your interest in the company and the broader textile industry. Learn about the organization’s history, products, and reputation. Research industry trends, advancements in winding technology, and best practices to show that you are up-to-date on the latest developments.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating and troubleshooting winding equipment. Discuss your experience with different types of fabrics, winding patterns, and quality control procedures. Provide specific examples of how you have optimized production processes and resolved technical issues.

3. Showcase Your Attention to Detail

Cloth Winding demands a keen eye for detail. In your interview, highlight your ability to identify and correct even the smallest defects or irregularities in the fabric. Describe your quality control methods and commitment to maintaining high standards.

4. Emphasize Your Safety Awareness

Safety is paramount in a manufacturing environment. Communicate your understanding of safety protocols and regulations related to the operation of winding machines. Mention your experience in adhering to safety guidelines and promoting a safe work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cloth Winder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!