Are you gearing up for an interview for a Coning Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Coning Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

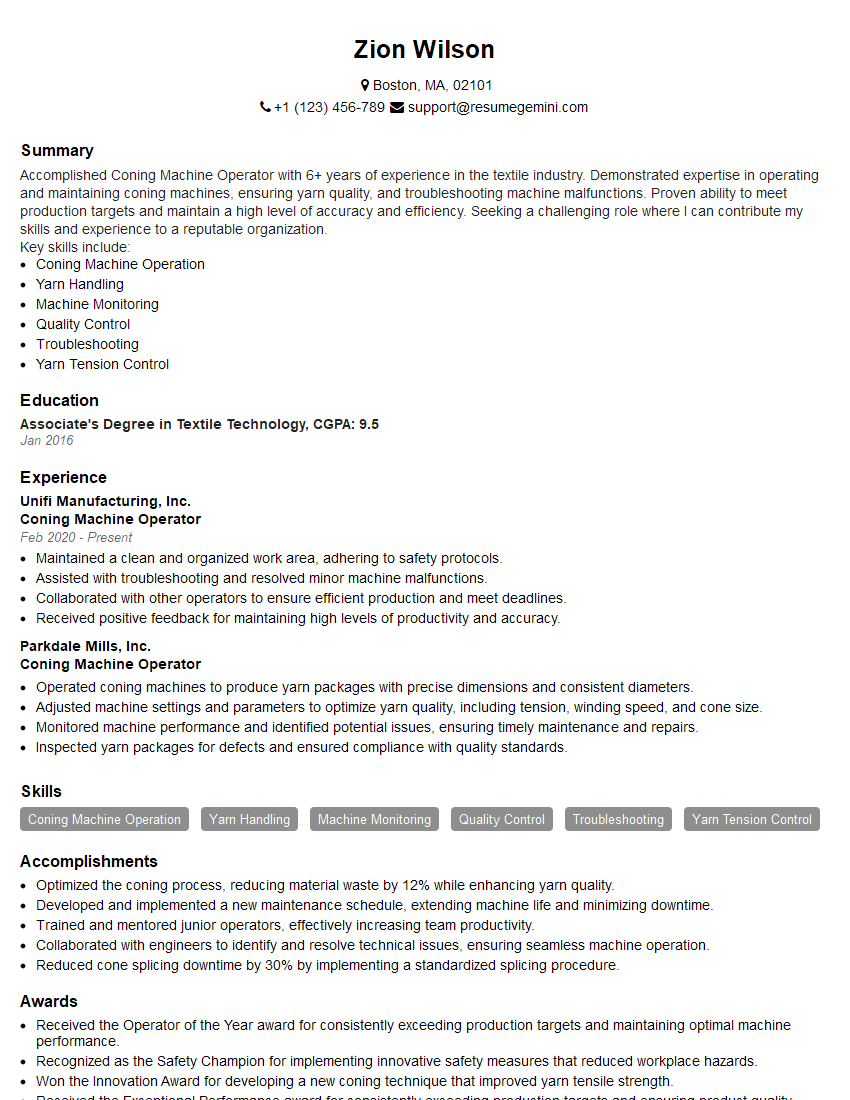

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coning Machine Operator

1. Describe the types of coning machines and their primary functions.

- Servo motor coning machine: This type of machine uses a servo motor to control the winding speed and tension, resulting in high-precision winding.

- Step motor coning machine: This type of machine uses a step motor to control the winding speed and tension, offering a cost-effective solution for basic winding applications.

- Pneumatic coning machine: This type of machine uses pneumatic pressure to control the winding speed and tension, providing high winding speeds.

- Automatic coning machine: This type of machine automates the entire winding process, including yarn feeding, winding, and doffing, reducing labor costs and improving efficiency.

2. Explain the importance of proper yarn tension control during coning.

Yarn breakage prevention

- Maintaining optimal yarn tension prevents excessive tension, which can cause yarn breakage.

Consistent winding quality

- Proper tension control ensures uniform winding tension, resulting in consistent yarn package density and winding quality.

Increased productivity

- Minimizing yarn breakage reduces machine downtime and increases overall productivity.

3. Describe the steps involved in setting up a coning machine for a specific yarn type.

- Determine the appropriate winding parameters (speed, tension, etc.) based on the yarn type and desired package specifications.

- Install the correct yarn guide and tensioner according to the yarn characteristics.

- Set the machine to the desired winding speed and tension settings.

- Thread the yarn through the machine and adjust the yarn path for optimal flow.

- Run a test run to verify the winding quality and make necessary adjustments.

4. How do you troubleshoot common coning machine problems, such as yarn tangling or uneven winding?

- Yarn Tangling:

- Check for obstructions in the yarn path, such as loose threads or foreign objects.

- Adjust the yarn tension to prevent excessive slack or tension.

- Inspect the yarn guide and tensioner for wear or damage.

- Uneven Winding:

- Verify that the winding parameters are set correctly for the yarn type.

- Check the yarn guide and tensioner for proper alignment and adjustment.

- Inspect the yarn package for any imperfections or damage.

5. How do you maintain and calibrate a coning machine to ensure optimal performance?

- Regular cleaning and lubrication of machine components.

- Periodic inspection and replacement of worn or damaged parts.

- Calibration of tension sensors and speed control systems.

- Monitoring machine performance and making adjustments as necessary.

6. What quality control measures do you implement to ensure the production of high-quality yarn packages?

- Regular monitoring of winding quality parameters (speed, tension, density).

- Visual inspection of yarn packages for defects (knots, slubs, uneven winding).

- Yarn strength and elongation testing to ensure package integrity.

- Implementation of statistical process control (SPC) techniques.

7. Describe your experience in working with different types of yarns, such as natural fibers and synthetic blends.

- Experience in handling natural fibers (cotton, wool, silk) and their unique winding characteristics.

- Knowledge of synthetic blends (polyester, nylon, spandex) and their specific winding requirements.

- Ability to adjust machine parameters and winding techniques to accommodate different yarn types.

8. How do you stay updated with the latest advancements in coning machine technology?

- Attending industry conferences and exhibitions.

- Reading technical publications and research papers.

- Networking with other professionals in the field.

- Seeking training opportunities provided by machine manufacturers.

9. Describe a time when you successfully solved a complex problem related to coning machine operation.

- Identification of the problem and its potential causes.

- Systematic troubleshooting and analysis.

- Implementation of a solution that effectively resolved the issue.

- Evaluation of the solution and its impact on machine performance.

10. What are your career goals as a Coning Machine Operator?

- To contribute to the production of high-quality yarn packages.

- To continuously improve my technical skills and knowledge in coning machine operation.

- To advance my career and take on leadership responsibilities within the organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coning Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coning Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coning Machine Operators play a crucial role in textile and yarn manufacturing industries, responsible for operating and maintaining coning machines to produce high-quality yarn for various applications. Their key responsibilities include:

1. Machine Operation

Operate coning machines to wind yarn onto cones, ensuring precise winding patterns and tension control.

- Set up and adjust machine parameters, such as winding speed, tension, and cone dimensions.

- Monitor machine operation, identify and address any issues promptly to prevent machine downtime.

2. Material Handling

Handle yarn cones safely and efficiently, ensuring proper storage and transportation to prevent damage.

- Unload yarn from delivery packages, inspect for quality, and prepare it for coning.

- Transfer finished cones to packaging and storage areas, maintaining proper inventory records.

3. Quality Control

Inspect yarn cones for defects, such as uneven winding, knotting, or contamination, and ensure adherence to quality standards.

- Calibrate and maintain testing equipment to ensure accurate quality checks.

- Document and report any quality issues or concerns to supervisors promptly.

4. Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting on coning machines to ensure optimal performance and prevent breakdowns.

- Clean and lubricate machine components as per manufacturer’s instructions.

- Identify and resolve minor machine malfunctions, consult with maintenance personnel for major repairs.

Interview Tips

To ace the interview for a Coning Machine Operator position, candidates should prepare thoroughly and focus on demonstrating their skills, experience, and enthusiasm for the role. Here are some interview tips to help them prepare:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, industry, and culture. Research the specific job description to understand the key responsibilities, skills, and qualifications required.

2. Highlight Relevant Skills and Experience

Emphasize your previous experience in operating coning machines or similar textile machinery. Showcase your proficiency in handling yarn, maintaining machines, and ensuring quality control.

3. Prepare for Technical Questions

Anticipate technical questions about coning machine operation, maintenance, and troubleshooting. Refresh your knowledge on machine components, winding techniques, and quality standards.

4. Demonstrate Attention to Detail

Coning Machine Operators must have a keen eye for detail to ensure yarn quality and machine performance. Highlight your ability to identify and correct deviations in winding patterns, tension, or machine operation.

5. Showcase Teamwork Skills

In a manufacturing environment, collaboration is crucial. Emphasize your ability to work effectively in a team, communicate clearly, and support colleagues.

6. Prepare Questions to Ask

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role. Prepare questions about the company’s production processes, quality control measures, or advancement opportunities.

Additional Tips:

- Dress professionally and arrive on time for the interview.

- Be confident, enthusiastic, and communicate your passion for the industry.

- Practice your answers to common interview questions beforehand.

- Be prepared to discuss your career goals and how they align with the company’s objectives.

- Follow up with the interviewer after the interview, expressing your appreciation and restating your interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coning Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!