Are you gearing up for an interview for a Industrial Twisting Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Industrial Twisting Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

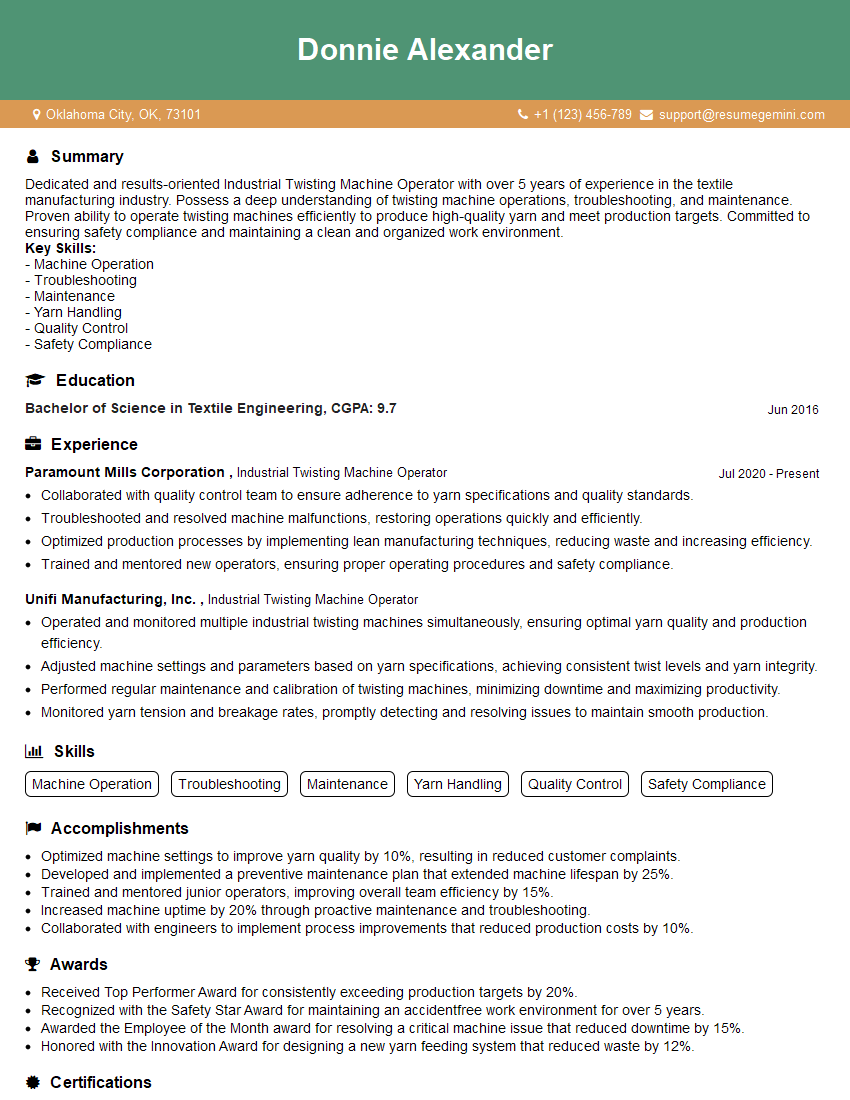

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Industrial Twisting Machine Operator

1. What are the key components of an industrial twisting machine and their functions?

- Creel: Holds the supply yarn packages.

- Tensioner: Controls the tension of the yarn during twisting.

- Twisting Head: Contains the twisting mechanism that creates the twist in the yarn.

- Take-up Unit: Collects the twisted yarn onto a package.

- Sensor: Monitors yarn parameters (e.g., tension, twist) and adjusts the machine settings accordingly.

2. Describe the different types of twisting machines based on their twisting methods.

Ring Twisting

- Yarn travels through stationary ring and rotating traveler.

- Produces high-quality, fine yarn with low hairiness.

Open-End Twisting

- Yarn travels through a rotating rotor.

- Produces bulkier, less hairy yarn at higher speeds.

Two-for-One Twisting

- Two strands are twisted together simultaneously.

- Produces strong, balanced yarn with improved elasticity.

3. What are the factors that influence the twist level in a yarn?

- Yarn size and count

- Fiber type and properties

- Twist direction and turns per inch (TPI)

- Machine speed

4. How do you troubleshoot common problems encountered during twisting?

- Yarn breakage: Check tension, twist level, and presence of knots or imperfections.

- Uneven twisting: Adjust tension settings or check for mechanical issues.

- Excessive hairiness: Reduce twist level or adjust traveler/rotor settings.

- Yarn slippage: Tighten tension or check take-up unit.

5. How do you maintain and calibrate an industrial twisting machine?

- Regular cleaning: Remove dust, debris, and yarn waste.

- Lubrication: Oil and grease moving parts as per manufacturer’s instructions.

- Calibration: Check and adjust tension, twist level, and other parameters using test equipment.

6. How do you ensure safety while operating a twisting machine?

- Wear appropriate PPE (e.g., gloves, earplugs, safety glasses).

- Follow proper machine start-up and shutdown procedures.

- Keep hands and body away from moving parts.

- Report any unsafe conditions or malfunctions immediately.

7. What quality control measures do you implement to ensure the quality of twisted yarn?

- Yarn testing: Conduct tests for strength, elongation, hairiness, and twist level.

- Visual inspection: Check for defects, unevenness, and other quality issues.

- Calibration and maintenance: Ensure machine is calibrated and maintained to produce consistent yarn quality.

8. How do you handle production schedules and meet deadlines?

- Prioritize orders based on urgency and customer needs.

- Optimize machine settings and minimize downtime.

- Communicate regularly with supervisors and other team members.

9. What are your strengths and weaknesses as an Industrial Twisting Machine Operator?

- Strengths: Technical knowledge, attention to detail, troubleshooting skills, ability to work independently.

- Weaknesses: Limited experience with certain yarn types, desire to improve efficiency.

10. Why are you interested in this position and what makes you a suitable candidate?

- Passion for yarn processing technology and desire to contribute to the production of high-quality yarn.

- Strong understanding of twisting principles and machine operations.

- Proven ability to troubleshoot and maintain equipment effectively.

- Commitment to safety, quality, and meeting production deadlines.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Industrial Twisting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Industrial Twisting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Industrial Twisting Machine Operators play a vital role in the textile industry, operating specialized machinery to produce twisted yarns. Their key responsibilities include:

1. Machine Operation

Operate and monitor industrial twisting machines to twist and package yarns according to specifications.

2. Quality Control

Inspect the quality of yarns and ensure they meet established standards.

3. Machine Maintenance

Perform basic maintenance and troubleshooting on twisting machines to ensure optimal performance.

4. Process Monitoring

Monitor the twisting process to ensure consistent yarn quality and meet production targets.

Interview Tips

1. Research the Company and Industry

Demonstrate your knowledge of the company and the textile industry. Research their products, competitors, and recent developments to show your interest and understanding of the field.

2. Practice Common Interview Questions

Prepare for common interview questions such as “Tell me about yourself,” “Why are you interested in this role?” and “What are your strengths and weaknesses?” Practice your answers to present yourself confidently and effectively.

3. Highlight Relevant Skills and Experience

Emphasize your technical skills related to twisting machine operation, quality control, and machine maintenance. Share specific examples of projects or responsibilities where you demonstrated these abilities.

4. Ask Informed Questions

Prepare thoughtful questions to show your engagement and interest in the position. Ask about company culture, growth opportunities, or specific aspects of the twisting machine operation process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Industrial Twisting Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.