Feeling lost in a sea of interview questions? Landed that dream interview for Open End Spinning Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Open End Spinning Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

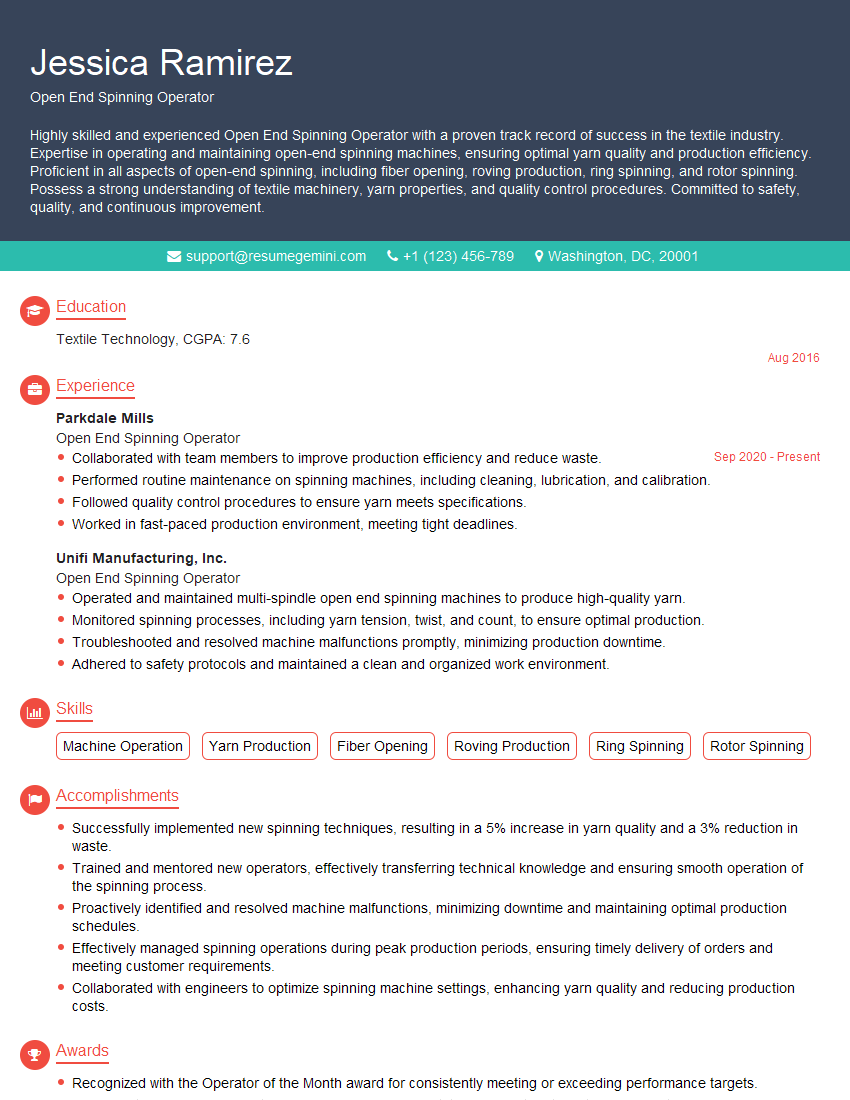

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Open End Spinning Operator

1. Explain the process of Open End Spinning?

Open End Spinning involves the following steps:

- Unwinding: Unwinding the sliver from the creel.

- Opening and Cleaning: Opening and cleaning the fibers using rollers and suction.

- Attentuating: Drawing out the fibers to reduce thickness.

- Spinning: Twisting the attenuating fibers to form yarn.

- Winding: Winding the spun yarn onto bobbins.

2. What are the main components of an Open End Spinning machine?

Rotor

- Rotor spins at high speeds to generate the twisting force.

Stator

- Stationary part that surrounds the rotor.

Suction System

- Removes impurities and generates air flow to control fiber movement.

Feeder

- Supplies sliver to the opening and cleaning zone.

Bobbin Winder

- Winds the spun yarn onto bobbins.

3. How does the yarn quality in Open End Spinning differ from conventional ring spinning?

Yarn produced by Open End Spinning typically has:

- Lower strength: Due to reduced fiber alignment.

- Higher bulk: Due to the presence of more fiber ends.

- Lower twist: Compared to ring-spun yarn.

- Fewer hairiness: As fibers are gripped and twisted inside the rotor.

4. What are the key factors that affect Open End Spinning efficiency?

- Sliver quality: Consistency and cleanliness of the sliver.

- Rotor speed: Higher speeds increase yarn strength but can cause excessive fiber breakage.

- Suction pressure: Regulates fiber movement and yarn quality.

- Feeder alignment: Affects the uniformity of yarn formation.

- Bobbin type: Affects yarn package density and tension.

5. Explain the maintenance procedures for Open End Spinning machines?

- Daily: Cleaning of rotors, stators, and suction nozzles.

- Weekly: Lubrication of bearings and inspection of belts.

- Monthly: Replacement of worn parts and calibration of sensors.

- Annually: Overhaul of machines to ensure optimal performance.

6. How do you troubleshoot common problems in Open End Spinning?

- Yarn breakage: Check rotor speed, suction pressure, and sliver quality.

- Uneven yarn: Adjust feeder alignment and check bobbin tension.

- High hairiness: Reduce rotor speed or adjust suction pressure.

- Low yarn strength: Optimize rotor speed and check sliver quality.

- Excessive waste: Check suction system and cleaning efficiency.

7. What are the advantages of Open End Spinning over other spinning methods?

- Higher production rates: Due to higher rotor speeds and continuous operation.

- Lower labor costs: Automated processes reduce the need for manual labor.

- Lower energy consumption: Compared to conventional spinning methods.

- Wider range of yarn counts: Can produce yarns from 5s to 60s.

- Suitable for shorter staple fibers: Can process fibers as short as 25mm.

8. What are the applications of Open End Spinning yarns?

- Apparel: Knitted and woven fabrics for clothing and home textiles.

- Industrial fabrics: Canvas, tarpaulins, and technical textiles.

- Nonwovens: Disposable products, wipes, and insulation materials.

- Carpet yarns: Low-cost, durable carpet fibers.

- Automotive: Interiors, seat covers, and headliners.

9. Describe the latest technological advancements in Open End Spinning?

- AI-powered process control: Optimizing machine parameters for improved efficiency.

- High-speed rotors: Increased production rates and yarn strength.

- Sensor-based monitoring: Real-time monitoring of yarn quality and process parameters.

- Automated yarn splicing: Reduced downtime and yarn wastage.

- Sustainability features: Minimizing energy consumption and waste generation.

10. What are your strengths and weaknesses as an Open End Spinning Operator?

Strengths:

- Expertise in operating and maintaining Open End Spinning machines.

- Strong troubleshooting skills and problem-solving abilities.

- Knowledge of yarn manufacturing processes and quality standards.

- Excellent communication and teamwork skills.

- High attention to detail and quality assurance.

Weaknesses:

- Limited experience with high-speed rotors.

- Need to improve proficiency in automated yarn splicing techniques.

I am actively seeking opportunities to develop in these areas and become a well-rounded Open End Spinning Operator.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Open End Spinning Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Open End Spinning Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Open End Spinning Operators are responsible for operating and maintaining open end spinning machines to produce yarn from cotton, synthetic, or blended fibers. Key responsibilities include:

1. Monitoring and Maintaining Spinning Machines

• Inspect machines for proper operation and identify potential issues

• Make necessary adjustments and repairs to ensure smooth operation

• Clean and lubricate machines as required

2. Producing High-Quality Yarn

• Set up and operate machines to produce yarn according to specifications

• Monitor yarn quality and make adjustments as needed

• Troubleshoot and resolve yarn production issues

3. Maintaining Inventory

• Keep track of raw materials and finished goods

• Order supplies and materials as needed

• Maintain inventory records

4. Ensuring Safety and Compliance

• Follow all safety regulations and procedures

• Maintain a clean and organized work area

• Comply with environmental and quality standards

Interview Tips

To ace an interview for an Open End Spinning Operator position, follow these tips:

1. Research the Company and Industry

• Gather information about the company’s history, products, and industry trends

• This will help you answer questions intelligently and show your enthusiasm for the role

2. Practice Your Answers

• Prepare responses to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

• Practice delivering your answers clearly and confidently

3. Highlight Your Skills and Experience

• Emphasize your technical abilities, such as machine operation, yarn production, and troubleshooting

• Highlight any previous experience in the textile industry

4. Be Prepared to Discuss Safety

• Interviewers will want to know that you understand and prioritize safety

• Be prepared to discuss your knowledge of safety procedures and your commitment to maintaining a safe work environment

5. Dress Professionally and Be On Time

• Show that you respect the company and the interviewer by dressing appropriately

• Punctuality demonstrates your reliability and professionalism

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Open End Spinning Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.