Are you gearing up for an interview for a Rayon Winder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Rayon Winder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

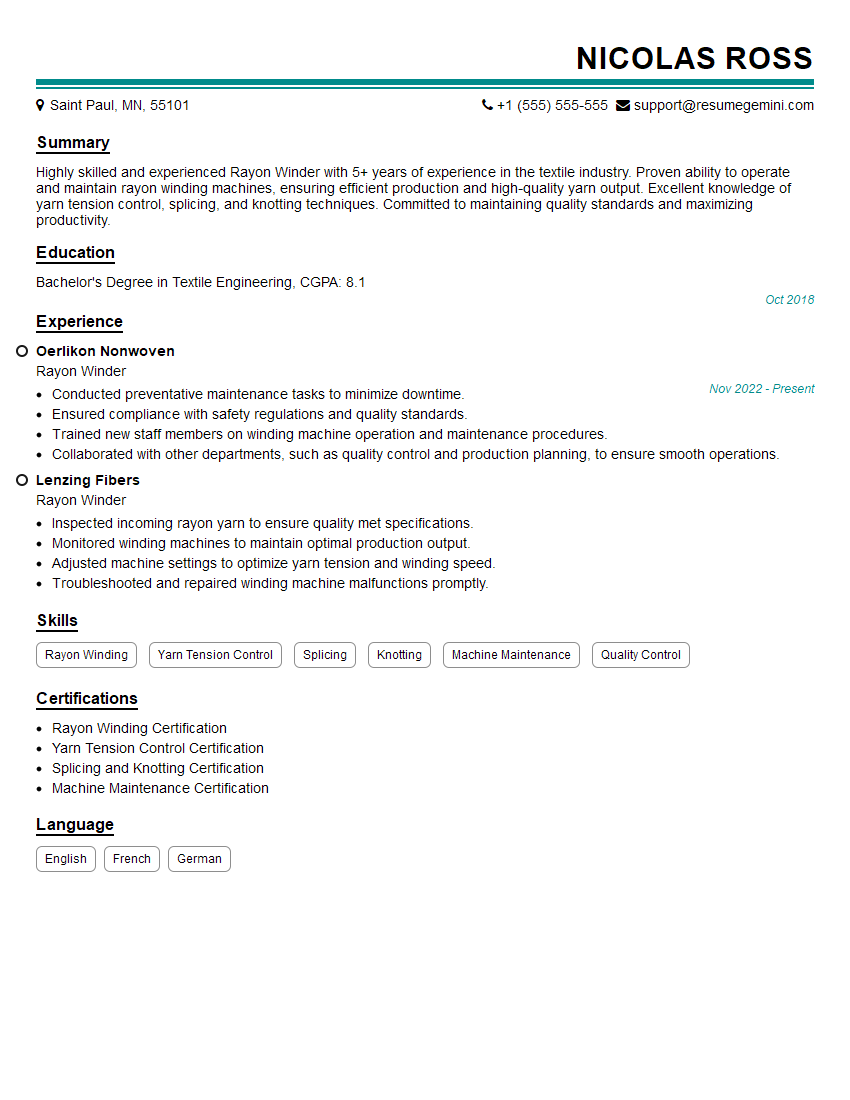

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rayon Winder

1. Explain the basic principles of rayon winding?

Rayon winding is a process of winding rayon yarn onto a bobbin or reel. The main principles involved in rayon winding are:

- Tension control: Maintaining a consistent tension on the yarn during winding is crucial to ensure the desired quality and uniformity of the wound package.

- Traverse motion: The yarn is wound back and forth across the bobbin or reel, creating a uniform and balanced package.

- Speed control: The speed of winding is carefully controlled to achieve the desired yarn package density and minimize yarn breakage.

2. Describe the different types of rayon winding machines?

Automatic Winding Machines

- High-speed, automated machines

- Precise tension control and traverse motion

- Reduced manual intervention

Semi-Automatic Winding Machines

- Manual loading of bobbins or reels

- Automatic tension and traverse control

- Suitable for smaller production runs

Manual Winding Machines

- Completely manual operation

- Less precise than automated machines

- Used for specialty yarns or low-volume production

3. What are the key factors that affect the quality of wound rayon packages?

- Yarn tension: Excessive tension can break the yarn, while insufficient tension can lead to loose or uneven winding.

- Traverse angle: The angle at which the yarn traverses the bobbin or reel affects the density and uniformity of the package.

- Winding speed: Too high a speed can cause yarn breakage, while too low a speed can result in uneven winding.

- Yarn characteristics: The type and properties of the rayon yarn, such as its strength, elasticity, and twist, can influence the winding process.

4. How do you troubleshoot common problems that occur during rayon winding?

- Yarn breakage: Check tension settings, winding speed, and yarn quality.

- Uneven winding: Adjust traverse angle, tension, or winding speed.

- Loose packages: Increase tension or reduce winding speed.

- Mechanical issues: Inspect the machine for any faults or misalignments.

5. Explain the role of tension control in rayon winding?

Tension control is critical in rayon winding as it:

- Prevents yarn breakage: Maintaining proper tension ensures that the yarn does not snap under stress.

- Ensures uniform winding: Consistent tension helps create a smooth and even package.

- Improves package density: Adequate tension results in a compact and tightly wound package.

- Minimizes yarn defects: Reduced tension minimizes yarn stretching and other defects that can affect its quality.

6. How do you optimize winding speed for rayon yarn?

Optimizing winding speed depends on several factors:

- Yarn characteristics: Strength, elasticity, and twist of the yarn.

- Machine capabilities: Winder speed range and tension control.

- Desired package density: Higher speed can result in looser packages.

- Yarn breakage risk: Too high speed can increase the likelihood of yarn breakage.

The optimal speed is determined by experimentation and experience to achieve a balance between production efficiency and yarn quality.

7. Discuss the importance of proper traverse motion in rayon winding?

Proper traverse motion is crucial for rayon winding as it:

- Creates uniform winding: The yarn is laid back and forth across the bobbin or reel, ensuring a balanced and even package.

- Prevents yarn overlap: Consistent traverse motion minimizes yarn overlapping and potential tangling.

- Improves package density: The alternating motion allows for tighter winding and a more compact package.

- Reduces yarn stress: Proper traverse motion prevents excessive stretching or tension on the yarn during winding.

8. Describe the maintenance procedures for rayon winding machines?

- Regular cleaning: Remove dust, yarn debris, and oil buildup to ensure smooth operation.

- Tension system inspection: Check tension settings, disk condition, and brake adjustment.

- Traverse mechanism maintenance: Lubricate moving parts and ensure proper alignment.

- Electrical system inspection: Check for loose connections, worn wires, and proper grounding.

- Software updates: Install software updates to address any issues or improve functionality.

9. How do you handle rayon yarn that is prone to breakage during winding?

- Reduce tension: Lowering the tension settings can minimize yarn stress and reduce breakage.

- Use a yarn conditioner: Applying a yarn conditioner or lubricant can enhance yarn strength and reduce friction.

- Inspect yarn quality: Check for any weak spots, knots, or unevenness in the yarn before winding.

- Adjust winding speed: Slower winding speeds can give the yarn more time to adjust and reduce breakage.

- Optimize traverse motion: Ensure a consistent and balanced traverse motion to avoid yarn overlapping and stress points.

10. What are the safety precautions that should be followed when operating rayon winding machines?

- Wear appropriate clothing: Avoid loose clothing or jewelry that could get caught in the machine.

- Use safety glasses: Protect eyes from flying debris or yarn breakage.

- Keep work area clean: Remove any tripping hazards or obstructions around the machine.

- Be aware of moving parts: Keep hands and other body parts away from rotating or moving components.

- Follow lockout/tagout procedures: Isolate the machine from power before performing maintenance or repairs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rayon Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rayon Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rayon Winder is responsible for operating machines that wind rayon yarn onto bobbins or other packages. This role plays a crucial part in the textile manufacturing process by ensuring the smooth and efficient transfer of yarn for further processing.

1. Machine Operation

Operate and monitor rayon winding machines to wind yarn onto bobbins or other packages.

- Set up and adjust machine settings, such as winding speed, tension, and bobbin size.

- Monitor yarn quality and ensure proper winding tension.

- Troubleshoot and resolve machine malfunctions.

2. Yarn Inspection

Inspect the wound yarn for defects, such as breaks, knots, or uneven winding.

- Identify and remove defective yarn.

- Maintain accurate records of yarn quality and production.

3. Bobbin Handling

Handle bobbins with care to prevent damage to the yarn.

- Load and unload bobbins from machine.

- Store and organize bobbins for further processing.

4. Maintenance

Perform basic maintenance on winding machines.

- Clean and lubricate machines.

- Replace worn or damaged parts.

5. Safety

Follow safety procedures and wear appropriate personal protective equipment.

- Maintain a clean and safe work area.

- Report any hazards or accidents.

Interview Tips

Preparing for a Rayon Winder interview requires researching the industry, understanding the key job responsibilities, and practicing your answers to common interview questions. Here are some tips to help you ace your interview:

1. Research the Company and Industry

Visit the company’s website and familiarize yourself with their products, services, and culture. Research the textile industry, including current trends and challenges.

2. Practice Common Interview Questions

Prepare for questions about your experience with rayon winding machines, yarn quality inspection, and bobbin handling. Practice answering questions about your safety practices and commitment to quality.

3. Highlight Relevant Skills

Emphasize your attention to detail, problem-solving abilities, and commitment to safety. Share examples of how you have handled machine malfunctions or identified and resolved yarn defects.

4. Show Enthusiasm and Curiosity

Express your interest in the rayon winding process and the textile industry. Ask questions about the company’s production goals, quality standards, and opportunities for growth.

5. Be Professional and Dress Appropriately

Dress professionally and arrive on time for your interview. Be polite and respectful to the interviewer and ask questions to demonstrate your interest.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rayon Winder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.