Are you gearing up for a career in Ribbon Winder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Ribbon Winder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

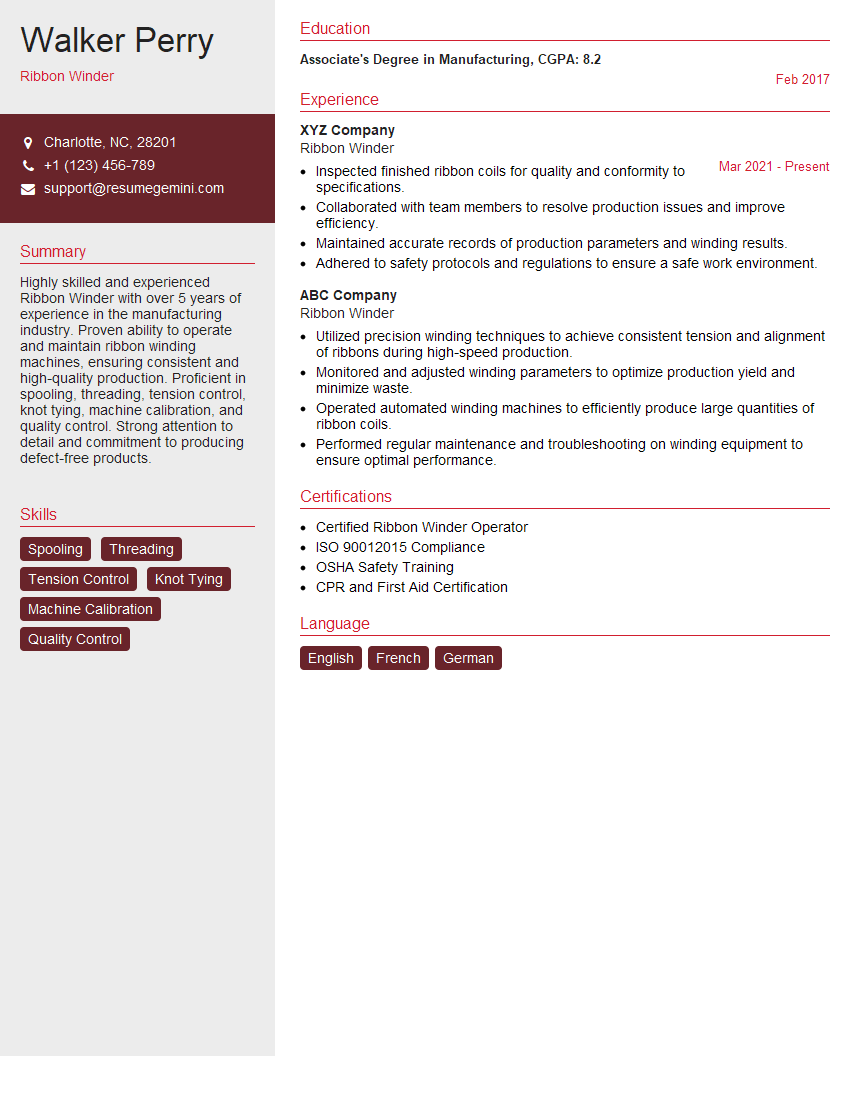

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ribbon Winder

1. What are the different types of ribbon winders available?

- Manual Ribbon Winders: These are hand-operated and require a skilled operator to guide the ribbon onto the core.

- Semi-Automatic Ribbon Winders: These machines have a motor to drive the winding process, but the operator still needs to manually load and unload the ribbon and core.

- Fully-Automatic Ribbon Winders: These machines automate the entire winding process, including loading and unloading the ribbon and core, and can be programmed to wind ribbon to precise specifications.

2. What are the key factors to consider when selecting a ribbon winder?

Factors for Consideration

- Ribbon width and thickness

- Core size and material

- Winding speed and tension

- Level of automation required

- Budget and space constraints

Important Factors

- The ribbon winder should be able to handle the specific type and size of ribbon you will be winding.

- It should have the necessary winding speed and tension controls to produce high-quality rolls.

- The level of automation should meet your production requirements and budget.

3. What are the common problems encountered during ribbon winding?

- Ribbon breakage: This can be caused by excessive tension, improper core preparation, or sharp edges on the winding equipment.

- Uneven winding: This can result from incorrect tension settings, worn or damaged rollers, or misaligned guides.

- Core wobble: This can be caused by an improperly sized or damaged core, or by excessive winding tension.

- Telescoping: This occurs when the inner layers of the wound ribbon slip, causing the roll to become loose and unstable.

4. How do you troubleshoot and resolve ribbon winding problems?

- Ribbon breakage: Check tension settings, core condition, and winding equipment for sharp edges.

- Uneven winding: Adjust tension settings, inspect rollers and guides for wear or damage, and ensure alignment is correct.

- Core wobble: Verify core size and condition, and adjust winding tension.

- Telescoping: Rewind the ribbon using proper tension settings and ensure the core is securely fastened.

5. What are the safety precautions to observe when operating a ribbon winder?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and closed-toe shoes.

- Keep loose clothing, hair, and jewelry away from moving parts.

- Never attempt to operate the machine with the guards removed.

- Be aware ofpinch points and sharp edges.

- Follow all manufacturer’s instructions for safe operation and maintenance.

6. What are the preventive maintenance tasks for a ribbon winder?

- Regularly clean and lubricate all moving parts and components.

- Inspect rollers, guides, and tension controls for wear or damage.

- Check and adjust tension settings to ensure optimal winding quality.

- Clean or replace air filters to prevent dust and debris buildup.

- Follow the manufacturer’s recommended maintenance schedule for specific machine.

7. How do you calculate the amount of ribbon required for a specific winding job?

- Determine the circumference of the core (π x diameter).

- Multiply the circumference by the number of layers required.

- Add 10-15% for waste and handling.

- For example, for a 1-inch core with 10 layers, the calculation would be: (3.14 x 1) x 10 x 1.15 = 34.54 inches.

8. What techniques can be used to improve the quality of wound ribbon rolls?

- Use high-quality ribbon and cores.

- Ensure proper tension settings.

- Keep the winding area clean and free of dust and debris.

- Use a winding machine that is well-maintained and calibrated.

- Follow the manufacturer’s instructions for optimal operation.

9. What are the different methods used to package and store wound ribbon rolls?

- Shrink wrapping: This method uses heat to shrink a plastic film around the roll, providing protection and stability.

- Cardboard boxes: Rolls can be placed in individual boxes for added protection and organization.

- Plastic bags: Rolls can be sealed in plastic bags for moisture and dust resistance.

- Storage in a cool, dry, and dust-free environment is essential to maintain ribbon quality.

10. What are the environmental considerations related to ribbon winding?

- Use eco-friendly materials such as recycled cardboard and biodegradable films for packaging.

- Minimize waste by optimizing winding processes and using scrap ribbon for other applications.

- Dispose of used ribbon and cores responsibly to reduce landfill impact.

- Consider using low-energy winding machines to reduce energy consumption.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ribbon Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ribbon Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Ribbon Winder plays a crucial role in the manufacturing industry, primarily responsible for operating and maintaining ribbon winding machines used to produce various types of ribbons for packaging, printing, and other applications.

1. Machine Operation

Setting up and operating ribbon winding machines, ensuring they are correctly calibrated and functioning optimally.

- Loading and unloading rolls of ribbon material onto the machine.

- Monitoring the winding process, adjusting tension and speed settings as necessary to maintain product quality.

2. Quality Control

Inspecting wound ribbons for defects such as tears, breaks, or misalignments.

- Adhering to established quality standards and specifications to ensure the production of high-quality ribbons.

- Identifying and reporting any deviations from quality standards for corrective action.

3. Maintenance and Troubleshooting

Performing routine maintenance and cleaning of ribbon winding machines.

- Troubleshooting and resolving machine malfunctions, ensuring minimal downtime.

- Identifying the need for repairs or replacements of machine components.

- Keeping a record of all maintenance activities for future reference.

4. Production Monitoring

Monitoring production output and ensuring that it meets or exceeds established targets.

- Making adjustments to the winding process as necessary to optimize efficiency and productivity.

- Collaborating with other production team members to coordinate workflow and resolve any issues.

Interview Tips

To enhance your chances of success in an interview for a Ribbon Winder position, consider the following tips:

1. Research and Practice

Thoroughly research the company, the industry, and the specific role you are applying for. Practice common interview questions and prepare thoughtful responses that highlight your qualifications and experiences that are most relevant to the job.

- Familiarize yourself with different types of ribbon winding machines and their functionalities.

- Practice describing your experience in identifying and resolving machine malfunctions.

2. Emphasize Attention to Detail

Stress your strong attention to detail and meticulous work habits. Explain how you take pride in producing high-quality ribbons and ensuring that they meet or exceed customer specifications.

- Provide examples of your ability to identify and correct errors in the winding process.

- Mention your commitment to maintaining a clean and organized work area.

3. Highlight Problem-Solving Skills

Emphasize your ability to identify, analyze, and resolve problems that may arise during the winding process. Explain how you use your problem-solving skills to maintain machine efficiency and ensure smooth production.

- Share a specific example of a time when you successfully resolved a ribbon winding machine issue.

- Discuss your approach to identifying the root cause of problems and developing effective solutions.

4. Demonstrate Teamwork and Communication Skills

Highlight your teamwork and communication skills, emphasizing your ability to collaborate with production team members to achieve common goals. Explain how you effectively communicate any issues or concerns with supervisors or colleagues.

- Provide an example of how you worked effectively with a team to resolve a production problem.

- Describe how you keep your supervisors and colleagues informed about your work progress and any challenges you may encounter.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Ribbon Winder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.