Are you gearing up for an interview for a Rope Machine Setter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Rope Machine Setter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

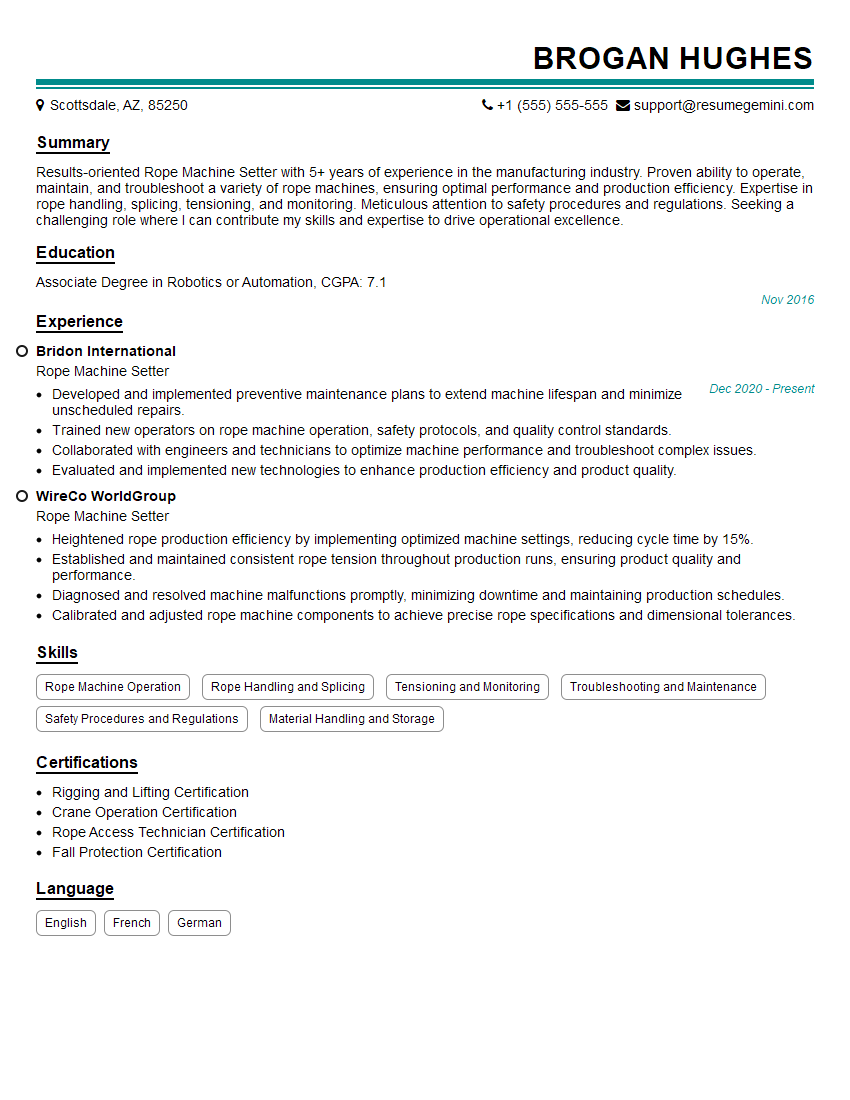

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rope Machine Setter

1. Describe the process of setting up and calibrating a rope winding machine?

The process of setting up and calibrating a rope winding machine involves several key steps:

- Machine Preparation: The machine should be placed on a level surface and secured firmly. Power supply and any necessary utilities should be connected.

- Tension Arm Adjustment: The tension arm is responsible for applying the correct tension to the rope during winding. Adjust the tension arm based on the rope specifications and the desired winding tension.

- Spool Loading: Load the empty spool onto the machine’s spindle and secure it properly.

- Rope Preparation: The rope should be free of tangles and kinks. Measure and cut the rope to the desired length, considering the required overlap.

- Rope Threading: Thread the rope through the tension arm, over the spool, and through the winding guide. Ensure that the rope is aligned properly and has the correct number of turns around the spool.

- Calibration: Perform calibration runs to determine the optimal winding speed and pitch. Adjust the machine settings accordingly to achieve the desired rope tension and winding density.

2. What are the different types of rope winding patterns and how do you determine the appropriate pattern for a specific application?

Winding Patterns:

- Parallel Winding: Ropes are wound side by side, resulting in a flat and dense winding.

- Cross Winding: Ropes are wound in a crisscross pattern, creating a more compact and stable winding.

- Helical Winding: Ropes are wound in a helical pattern, providing a more uniform distribution of tension.

Pattern Selection:

- Rope Properties: Consider the diameter, material, and elasticity of the rope.

- Winding Tension: Different patterns can withstand varying levels of tension.

- Application Requirements: Determine the desired compactness, stability, and tension distribution for the specific application.

3. How do you troubleshoot common rope winding machine problems, such as uneven winding, excessive rope tension, and rope breakage?

- Uneven Winding: Check for any misalignment in the rope threading, tension arm, or winding guide. Adjust the settings accordingly.

- Excessive Rope Tension: Adjust the tension arm to reduce tension. Verify that the rope is not excessively twisted or tangled.

- Rope Breakage: Inspect the rope for damage or defects. Check if the winding tension is too high. Ensure that the rope is properly threaded and not kinked.

4. What safety precautions should be taken when operating a rope winding machine?

- Machine Operation: Follow the manufacturer’s instructions for safe machine operation.

- Personal Safety Gear: Wear appropriate safety gear, including gloves, safety glasses, and ear protection.

- Guarding: Ensure that all machine guards are in place and functional.

- Electrical Safety: Check electrical connections regularly and ensure proper grounding.

- Emergency Stop: Familiarize yourself with the emergency stop button and be prepared to use it in case of any hazards.

5. How do you maintain a rope winding machine to ensure optimal performance and longevity?

- Regular Cleaning: Keep the machine clean of debris and dust to prevent malfunctions.

- Lubrication: Follow the manufacturer’s recommendations for lubrication to ensure smooth operation.

- Tension Adjustment: Regularly check and adjust the tension arm to maintain the desired winding tension.

- Rope Inspection: Inspect the rope for any damage or wear and replace it as necessary.

- Electrical Check-Ups: Conduct periodic electrical inspections to ensure proper wiring and connections.

6. What are the different types of ropes used in industrial applications, and how do their properties affect their suitability for specific tasks?

- Natural Fiber Ropes (Sisal, Manila, Cotton): Strong, durable, and biodegradable, suitable for general-purpose applications.

- Synthetic Fiber Ropes (Polyester, Nylon, Polypropylene): Lightweight, high-strength, and resistant to chemicals and UV, ideal for marine and industrial use.

- Wire Ropes: Strongest and most durable, used for heavy lifting, construction, and mining.

7. Explain the importance of proper rope storage and how it affects the rope’s performance and lifespan?

- Dry and Cool Environment: Store ropes in a dry and cool place to prevent moisture and heat damage.

- Proper Winding: Store ropes loosely coiled or spooled to avoid kinks and tangles.

- UV Protection: Protect ropes from sunlight to prevent degradation caused by UV exposure.

- Inspection and Maintenance: Regularly inspect ropes for damage and perform necessary maintenance to extend their lifespan.

8. Describe the role of tension control in rope winding and how it affects the quality of the final product?

- Winding Quality: Optimal tension ensures uniform rope winding, preventing unevenness and breakage.

- Rope Strength: Proper tension maintains the rope’s strength and integrity, allowing it to withstand intended loads.

- Safety: Controlling tension reduces the risk of rope breakage, which can cause accidents.

9. What are the major factors that affect the efficiency of a rope winding machine, and how can you optimize it for maximum productivity?

- Machine Configuration: Choose a machine with the right tension control, winding speed, and spool capacity for the job.

- Rope Properties: Consider the rope’s diameter, material, and tension requirements.

- Operator Skill: Train operators to handle the machine efficiently and troubleshoot any issues.

- Maintenance: Regularly maintain the machine to prevent downtime and ensure optimal performance.

10. How do you stay updated on the latest advancements in rope winding technology, and what impact do these advancements have on the industry?

- Trade Shows and Conferences: Attend industry events to learn about new technologies and innovations.

- Technical Publications: Read industry journals and articles to stay informed about technological advancements.

- Manufacturer Updates: Stay connected with rope winding machine manufacturers to learn about product updates and new features.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rope Machine Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rope Machine Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rope Machine Setter is responsible for ensuring that rope machines are set up, maintained, and repaired to facilitate efficient and safe production of rope products. Key duties include:

1. Machine Setup and Operation

Setting up and operating rope machines by adjusting and aligning components to produce ropes that meet specifications.

- Calibrating and adjusting machine settings for optimal rope production.

- Monitoring machine performance to identify and resolve any issues promptly.

2. Maintenance and Repair

Performing preventive and corrective maintenance on rope machines to ensure smooth functioning and prevent breakdowns.

- Inspecting machines regularly, identifying potential issues, and taking corrective actions.

- Troubleshooting and repairing mechanical or electrical issues to minimize downtime and restore machine functionality.

3. Material Handling

Handling and managing raw materials (such as fibers and polymers) and finished ropes.

- Loading and unloading materials on and off machines.

- Ensuring proper storage and handling of materials to maintain quality and prevent damage.

4. Quality Control

Monitoring rope production to ensure adherence to quality standards and specifications.

- Inspecting ropes for defects, flaws, or non-conformances.

- Taking corrective actions or adjustments to improve rope quality.

Interview Tips

To ace your interview for a Rope Machine Setter position, consider the following tips:

1. Research the Company and Industry

Demonstrate your interest and knowledge of the company and the rope industry. Research the company’s products, competitors, and industry trends to show that you are informed and eager to contribute.

- Visit the company website and social media pages.

- Read industry news and articles.

2. Prepare for Technical Questions

Be prepared to answer questions about your technical skills and knowledge of rope machine operations. Practice explaining your experience and skills in detail.

- Review the key job responsibilities and highlight your relevant experience.

- Prepare examples of how you have successfully set up, operated, and maintained rope machines.

3. Emphasize Safety and Attention to Detail

Safety is paramount in any manufacturing environment. Showcase your commitment to following safety protocols and procedures.

- Highlight your knowledge of industry safety standards.

- Explain how you ensure that machines are operated safely and that proper safety equipment is used.

4. Highlight Your Teamwork Skills

Rope Machine Setters often work in teams. Highlight your ability to collaborate effectively and contribute to a team environment.

- Provide examples of how you have successfully worked with others to set up and operate rope machines.

- Demonstrate your ability to communicate clearly and work together to solve problems.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Rope Machine Setter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.