Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Spooling Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

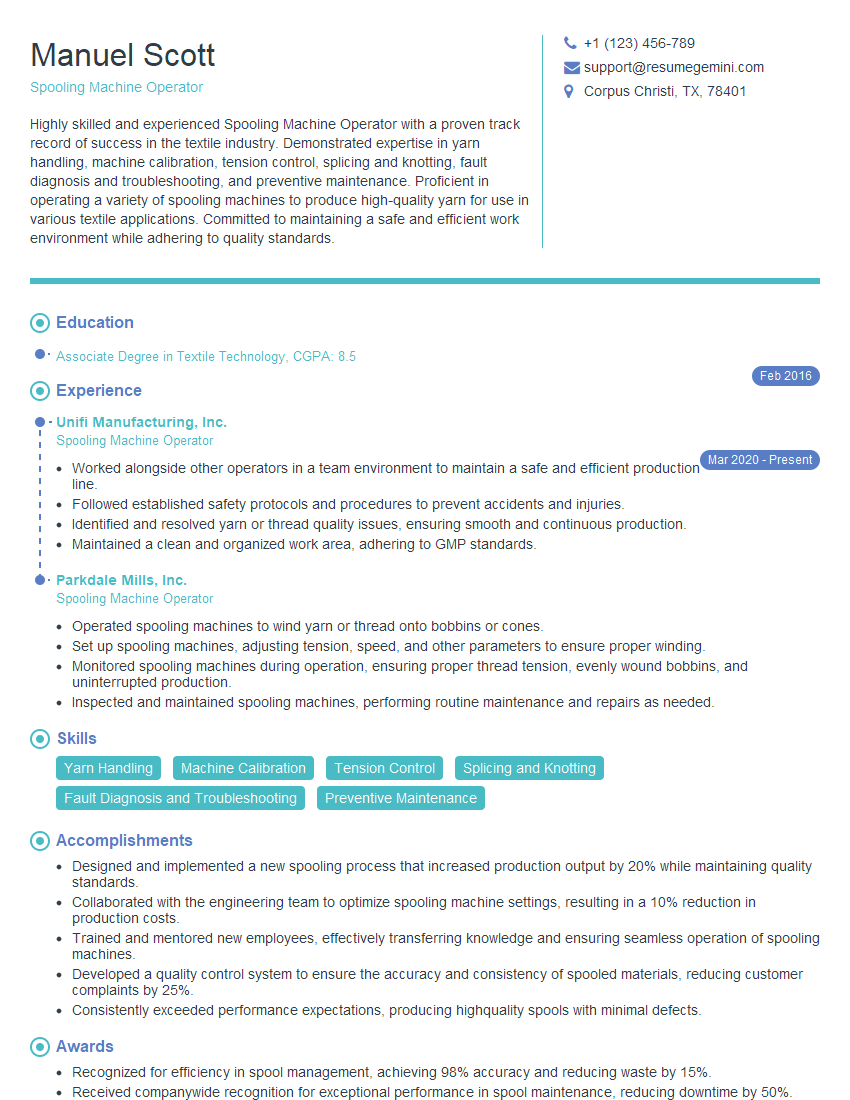

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spooling Machine Operator

1. What is the difference between a spool and a reel?

A spool is a cylindrical object with a flange at each end, used to hold thread, yarn, or wire. A reel is a disc-shaped object with a hub in the center, used to wind thread or yarn.

2. What are the different types of spooling machines?

Automatic spooling machines

- These machines are used to spool large quantities of thread or yarn.

- They are equipped with automatic tension control and can spool at high speeds.

Semi-automatic spooling machines

- These machines are used to spool smaller quantities of thread or yarn.

- They require manual tension control and are slower than automatic spooling machines.

Manual spooling machines

- These machines are used to spool small quantities of thread or yarn.

- They require manual tension control and are the slowest type of spooling machine.

3. What are the main components of a spooling machine?

- Headstock

- Tailstock

- Bobbin

- Spool

- Thread guide

- Tension control

4. How do you operate a spooling machine?

- Load the bobbin onto the headstock.

- Place the spool onto the tailstock.

- Thread the thread through the thread guide.

- Adjust the tension control.

- Start the machine.

5. What are the different types of thread used in spooling?

- Cotton

- Polyester

- Nylon

- Silk

- Wool

6. What are the different types of yarn used in spooling?

- Cotton

- Polyester

- Nylon

- Acrylic

- Wool

7. What are the different types of wire used in spooling?

- Copper

- Aluminum

- Steel

- Brass

- Nickel

8. What are the safety precautions that should be taken when operating a spooling machine?

- Wear safety glasses.

- Keep hands away from moving parts.

- Do not operate the machine if it is damaged.

- Do not attempt to repair the machine yourself.

- Follow all manufacturer’s instructions.

9. What are the most common problems that occur with spooling machines?

- Thread breakage

- Yarn breakage

- Wire breakage

- Tension problems

- Mechanical problems

10. How do you troubleshoot a spooling machine?

- Check the thread, yarn, or wire for damage.

- Check the tension control.

- Check for mechanical problems.

- Refer to the manufacturer’s instructions for troubleshooting.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spooling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spooling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Spooling Machine Operators play a crucial role in various industries by setting up, operating, and maintaining spooling machines. Their key responsibilities include:1. Machine Operation and Maintenance

Operate spooling machines to wind materials such as yarn, thread, or wire onto spools or reels.

Inspect and maintain machines to ensure optimal performance.

Identify and resolve machine malfunctions promptly.

2. Material Handling

Load and unload materials onto the spooling machine.

Inspect materials for defects or damage.

Monitor material flow and adjust machine settings as needed.

3. Quality Control

Ensure the accuracy and precision of spooling operations.

Check the quality of spooled materials and maintain quality standards.

Report any quality issues to supervisors or quality control personnel.

4. Production Monitoring

Monitor production output and maintain production schedules.

Identify and address production bottlenecks.

Coordinate with other operators and departments to ensure smooth production processes.

5. Recordkeeping

Maintain accurate records of production data.

Document machine maintenance and repairs.

Communicate production-related information to supervisors and management.

Interview Tips

To ace your Spooling Machine Operator interview, follow these preparation tips:1. Research the Job and Company

Thoroughly review the job description to understand the specific requirements of the role.

Research the company’s history, products, and industry to demonstrate your interest and knowledge.

2. Practice Your Answers to Common Questions

Prepare answers to standard interview questions, such as:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- Can you describe your experience operating spooling machines?

3. Highlight Your Technical Skills

Emphasize your technical abilities related to spooling machine operation, including:

- Machine setup and maintenance

- Material handling and quality control

- Production monitoring and recordkeeping

4. Demonstrate Your Problem-Solving Abilities

Provide examples of how you have identified and resolved machine or production issues.

Explain your troubleshooting process and the steps you took to rectify problems.

5. Show Enthusiasm and Team Spirit

Express your passion for the role and the industry.

Highlight your ability to work effectively in a team environment and contribute to a productive workplace.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Spooling Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Spooling Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.