Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Textile Draw-Out Machine Operator/Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

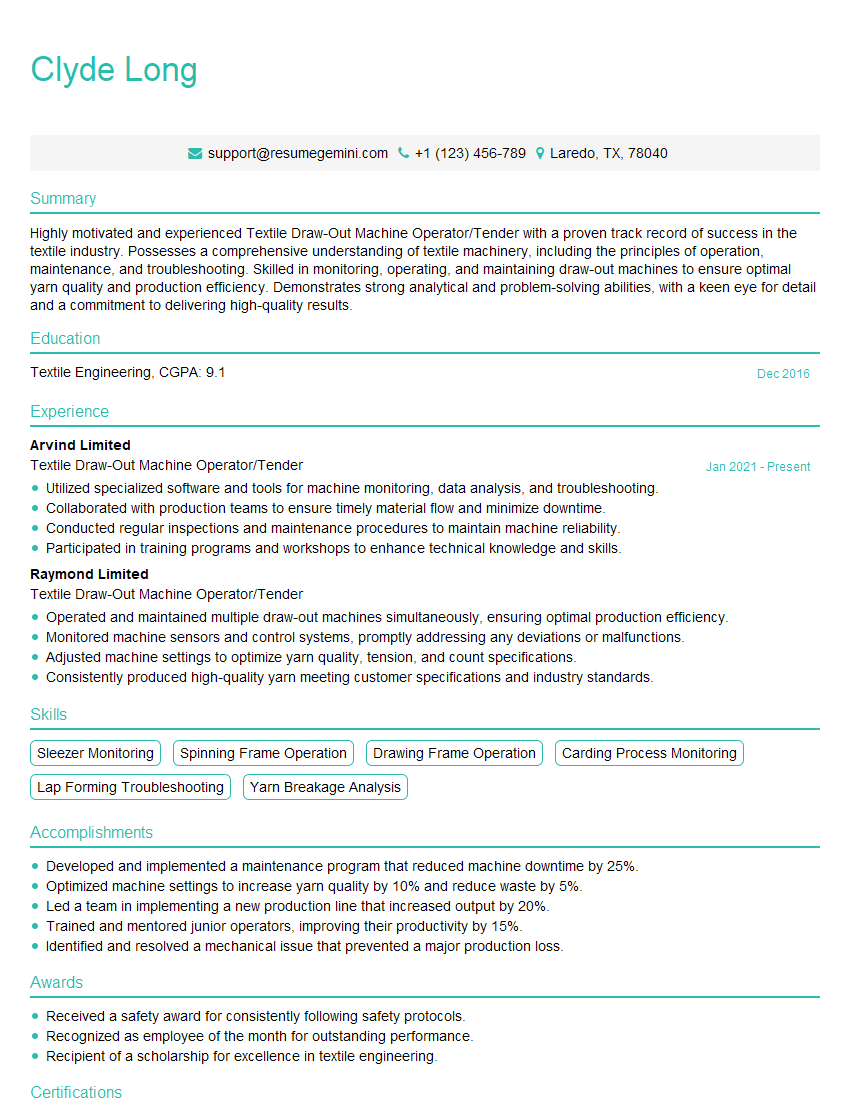

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Textile Draw-Out Machine Operator/Tender

1. Explain the role of a Draw-Out Machine Operator?

- Responsible for operating and maintaining Draw-Out machines to produce sliver or yarn.

- Monitor machine conditions, adjust settings, and make necessary repairs to ensure optimal performance.

- Adhere to quality standards and safety regulations, maintain cleanliness and orderliness in the work area.

2. How do you ensure the production of high-quality sliver or yarn?

3. Describe the mechanical components of a Draw-Out Machine and their functions?

- Creel: Holds and feeds the roving to the machine.

- Drafting Unit: Consists of pairs of rollers that draw and align the fibers to reduce diameter.

- Bobbin Winder: Collects the drawn-out sliver or yarn onto a bobbin.

- Control System: Monitors and adjusts machine parameters to maintain optimal performance.

4. What are the common problems that can occur during Draw-Out operations and how do you resolve them?

- Uneven sliver/yarn: Adjust drafting rollers and tension settings.

- Fiber breakage: Check roving quality, roller pressure, and machine alignment.

- Machine breakdowns: Perform regular maintenance, identify faulty components, and repair or replace as necessary.

- Quality deviations: Consult quality standards, inspect end products, and make necessary adjustments to machine settings or processes.

5. How do you maintain optimal machine efficiency and productivity?

- Regularly clean and lubricate machine components.

- Inspect and adjust machine settings to minimize downtime.

- Monitor production rates and identify areas for improvement.

- Communicate with supervisors and colleagues to share best practices and resolve any issues.

6. Explain the importance of adhering to safety guidelines in the Draw-Out operation?

- Protects operators from accidents.

- Prevents machine damage and production downtime.

- Maintains a safe and healthy work environment.

- Ensures compliance with regulatory requirements.

7. What are the different types of Draw-Out machines and their specific applications?

- Conventional Draw-Out: Used for producing various types of yarns.

- High-Speed Draw-Out: Produces high-tenacity yarns for specialized applications.

- Compact Draw-Out: Creates yarns with improved strength and smoothness.

- Semi-Automatic Draw-Out: Includes automated features for improved efficiency.

8. Explain the role of tension control in Draw-Out operations and how you maintain it?

- Proper tension ensures uniform sliver/yarn quality.

- Tension is controlled through settings on the drafting roller.

- Monitor tension levels using tension meters.

- Adjust tension settings as needed to maintain consistency.

9. Describe the process of setting up and calibrating a Draw-Out machine?

- Install and secure the machine.

- Calibrate drafting rollers to achieve desired draft ratio.

- Set tension settings based on yarn/sliver requirements.

- Test run the machine and make any necessary adjustments.

10. How do you manage downtime and minimize its impact on production?

- Perform regular preventive maintenance to reduce unplanned downtime.

- Train backup operators to ensure smooth shift transitions.

- Identify critical spares and maintain an inventory for quick replacement.

- Collaborate with maintenance team to resolve breakdowns swiftly.

11. What software applications or systems are used in Draw-Out operations and how do you utilize them?

- Production Monitoring Systems: Track machine performance and identify areas for improvement.

- Quality Control Systems: Analyze sliver/yarn quality and ensure adherence to specifications.

- Maintenance Management Systems: Schedule and track maintenance activities.

- Data Analysis Tools: Analyze production data, identify trends, and make data-driven decisions.

12. How do you stay updated with the latest advancements in Draw-Out technology and best practices?

- Attend industry conferences and exhibitions.

- Read technical journals and industry publications.

- Participate in training programs and workshops.

- Connect with experts and peers in the field.

13. What is your approach to working effectively in a team environment?

- Communicate clearly and share knowledge with colleagues.

- Collaborate to solve problems and improve processes.

- Support other team members and contribute to a positive work atmosphere.

- Take initiative and assist in various aspects of the operation.

14. Describe a situation where you had to troubleshoot and resolve a complex issue on a Draw-Out machine?

15. What are your career aspirations and how do you see yourself contributing to our organization?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Textile Draw-Out Machine Operator/Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Textile Draw-Out Machine Operator/Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Textile Draw-Out Machine Operator/Tender plays a crucial role in the textile industry, operating and maintaining draw-out machines that prepare fibers for spinning into yarn. The key responsibilities of this position include:

1. Machine Operation

Operating draw-out machines to draw fibers into a uniform sliver, ensuring fiber quality and consistency.

2. Machine Maintenance

Performing routine maintenance and repairs on draw-out machines, including cleaning, lubrication, and adjustments.

3. Quality Control

Monitoring the quality of drawn fibers, identifying and correcting any defects.

4. Production Monitoring

Tracking production rates, ensuring machinery efficiency, and identifying areas for improvement.

5. Safety Compliance

Adhering to safety regulations and protocols, maintaining a safe work environment.

Interview Tips

Preparing thoroughly for an interview is essential for success. Here are some tips for candidates applying for the Textile Draw-Out Machine Operator/Tender position:

1. Research the Company and Position

Gain a deep understanding of the company’s culture, values, and the specific responsibilities of the role.

2. Highlight Relevant Experience

Emphasize your experience in operating and maintaining textile machinery, particularly draw-out machines.

3. Quantify Your Accomplishments

Use specific metrics and examples to quantify your contributions in previous roles.

4. Demonstrate Problem-Solving Skills

Share instances where you identified and resolved issues related to machine operation or maintenance.

5. Show Enthusiasm and Willingness to Learn

Convey your passion for the textile industry and your eagerness to expand your knowledge and skills.

6. Practice Common Interview Questions

Prepare for common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

7. Dress Professionally

Make a good impression by dressing appropriately for the interview.

8. Be Punctual

Arrive on time for the interview to show respect for the interviewer’s schedule.

9. Follow Up

Send a thank-you note to the interviewer within 24 hours of the interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Textile Draw-Out Machine Operator/Tender role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.