Are you gearing up for an interview for a Tie in Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Tie in Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

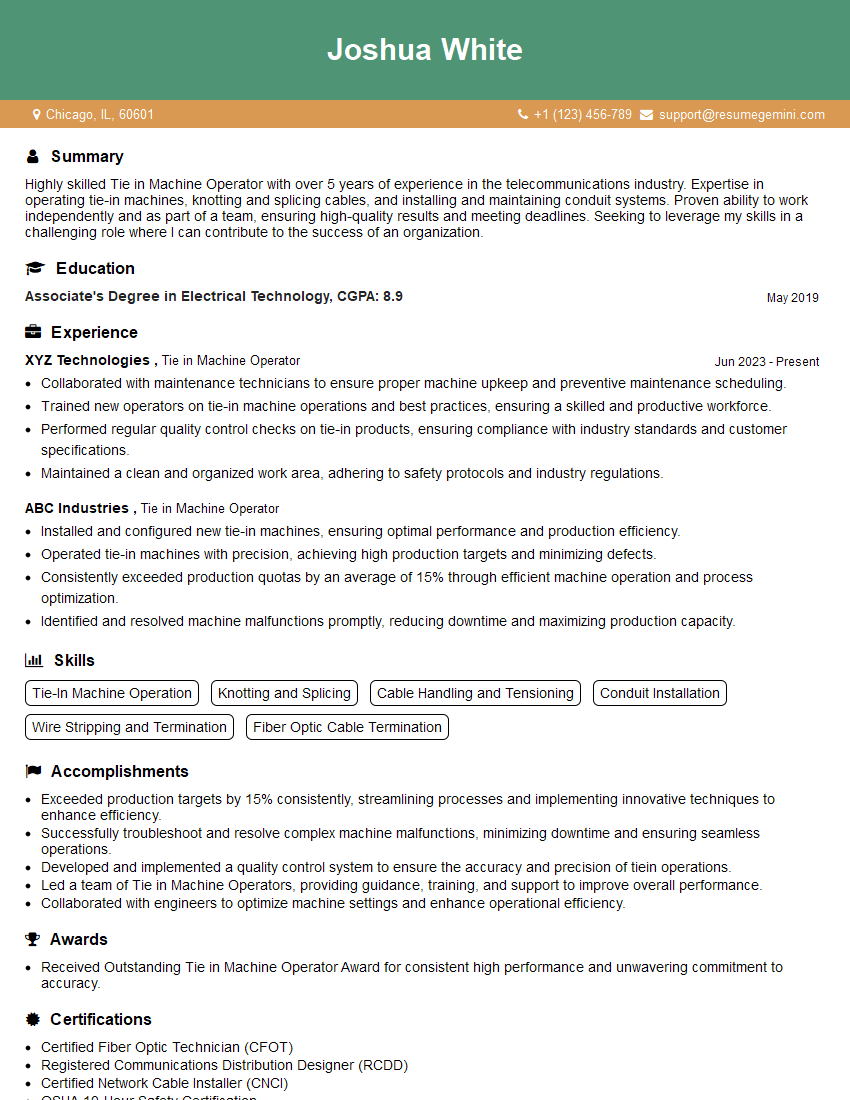

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tie in Machine Operator

1. Describe the process of setting up and operating a tie-in machine.

To set up and operate a tie-in machine, I follow this process:

- Inspect the machine: Before starting, I thoroughly inspect the machine to ensure it is in good working order. I check the tension, needles, and other components.

- Load the fabric: I carefully load the fabric onto the machine, ensuring it is aligned and tensioned correctly.

- Set the machine parameters: I adjust the machine’s settings, such as stitch length, tension, and speed, according to the fabric and desired stitch pattern.

- Start the machine: Once the machine is set up, I start it and monitor the stitching process.

- Make adjustments: During the stitching process, I observe the fabric and make adjustments as needed to maintain consistent stitch quality.

2. What are some common problems you have encountered while operating a tie-in machine? How did you resolve them?

Troubleshooting Techniques and Problem Resolution

- Broken needles: Broken needles can occur due to excessive tension or dull needles. I replace the broken needle and adjust the tension settings accordingly.

- Skipped stitches: Skipped stitches indicate problems with tension or needle alignment. I check the tension settings and ensure the fabric is not too thick or thin.

- Fabric damage: Machine malfunctions or incorrect settings can damage the fabric. I immediately stop the machine, inspect the fabric, and adjust the settings as necessary.

3. What types of fabrics can be processed on a tie-in machine? How do you adjust the machine settings for different fabrics?

Tie-in machines can handle various fabrics, including:

- Cotton

- Silk

- Wool

- Synthetics

To adjust the machine settings for different fabrics, I consider the following factors:

- Fabric thickness: Thicker fabrics require higher tension and longer stitch lengths.

- Fabric texture: Delicate fabrics like silk need gentle handling and lower tension.

- Stitch pattern: Different stitch patterns require specific tension and stitch length settings.

4. What is your experience with maintaining and repairing tie-in machines?

Throughout my experience, I have developed proficiency in maintaining and repairing tie-in machines. I perform regular maintenance tasks, such as:

- Cleaning and oiling the machine

- Replacing worn or damaged parts

- Calibrating the machine

For more complex repairs, I collaborate with experienced technicians or consult the manufacturer’s guidelines.

5. How do you ensure the quality of the finished product when operating a tie-in machine?

I maintain the quality of the finished product through the following measures:

- Careful fabric inspection: I examine the fabric before and during the stitching process to identify any potential defects.

- Regular machine maintenance: I ensure the machine is regularly maintained to prevent malfunctions and produce consistent stitch quality.

- Monitoring during stitching: I closely monitor the stitching process and make adjustments as needed to maintain stitch uniformity and prevent fabric damage.

- Quality control checks: I conduct thorough quality checks on the finished product to identify and correct any discrepancies.

6. What safety precautions do you observe when operating a tie-in machine?

Safety is paramount when operating a tie-in machine. I adhere to the following precautions:

- Proper attire: I wear appropriate clothing, including protective eyewear and gloves.

- Machine guarding: I ensure that all machine guards are in place and functioning correctly.

- Proper lifting techniques: I use proper body mechanics when lifting heavy materials.

- Emergency stop: I am familiar with the emergency stop procedures and know how to activate it in case of an emergency.

7. How do you troubleshoot common errors that may occur during the tie-in process?

Troubleshooting Common Errors

- Puckering: Puckering indicates excessive tension. I adjust the tension settings and ensure the fabric is evenly fed into the machine.

- Waving: Waving occurs when the fabric is not properly aligned. I realign the fabric and adjust the machine’s guide settings.

- Thread breakage: Thread breakage can be caused by worn needles or incorrect tension settings. I replace the needles and adjust the tension.

8. What techniques do you use to optimize the efficiency of the tie-in process?

I employ the following techniques to optimize efficiency:

- Proper machine setup: I ensure the machine is properly set up and calibrated to reduce downtime.

- Continuous fabric feeding: I maintain a consistent flow of fabric into the machine to prevent interruptions.

- Preventive maintenance: I perform regular maintenance tasks to minimize the risk of breakdowns.

- Skillful operation: I utilize my skills and experience to operate the machine smoothly and efficiently.

9. How do you handle variations in fabric quality and how do you adjust the machine settings accordingly?

Variations in fabric quality require adjustments to the machine settings:

- Fabric weight: I adjust the tension and stitch length based on the fabric weight.

- Fabric texture: Delicate fabrics require lower tension settings to prevent damage.

- Fabric stretch: I use specialized stitch patterns and adjust the tension to accommodate stretchable fabrics.

10. Describe the quality control procedures you follow to ensure the accuracy and precision of your work.

To ensure accuracy and precision, I follow these quality control procedures:

- Pre-production sampling: I create samples to test the machine settings and stitch quality before production.

- Regular inspections: I inspect the fabric and stitching throughout the production process.

- Dimensional checks: I use measuring tools to verify that the finished product meets the required dimensions.

- Customer feedback: I incorporate customer feedback into my quality control measures to continuously improve the process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tie in Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tie in Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tie in Machine Operators are skilled professionals who operate tie in machines to join two or more pieces of material together. They are responsible for ensuring that the tie in is secure and meets quality standards. Some of the key responsibilities of Tie in Machine Operators include:

1. Operating tie in machines

Tie in Machine Operators are responsible for operating tie in machines to join two or more pieces of material together. They must be able to set up the machine correctly and operate it safely and efficiently.

- Setting up the machine correctly

- Operating the machine safely and efficiently

- Monitoring the machine to ensure that it is operating properly

2. Inspecting materials

Tie in Machine Operators must inspect materials before they are joined to ensure that they are free of defects. They must also inspect the finished product to ensure that it meets quality standards.

- Inspecting materials before they are joined

- Inspecting the finished product to ensure that it meets quality standards

3. Maintaining equipment

Tie in Machine Operators are responsible for maintaining their equipment to ensure that it is in good working condition. They must be able to troubleshoot problems and make repairs as needed.

- Maintaining equipment to ensure that it is in good working condition

- Troubleshooting problems and making repairs as needed

4. Following safety procedures

Tie in Machine Operators must follow all safety procedures to ensure their safety and the safety of those around them. They must be aware of the hazards associated with their work and take steps to avoid them.

- Following all safety procedures

- Being aware of the hazards associated with their work

- Taking steps to avoid hazards

Interview Tips

Interviewing for a Tie in Machine Operator position can be a daunting task, but there are a few things you can do to prepare and increase your chances of success.

1. Research the company and the position

Before you go to your interview, it is important to do your research on the company and the position you are applying for. This will help you understand the company’s culture and values and the specific requirements of the job. You can find information about the company on their website, in their annual report, or in articles about the company in the news.

- Visit the company’s website

- Read the company’s annual report

- Read articles about the company in the news

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked, regardless of the position you are applying for. It is helpful to practice answering these questions in advance so that you can feel confident and prepared during your interview. Some common interview questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your career goals?

- Why should we hire you?

3. Prepare questions to ask the interviewer

Asking questions at the end of an interview shows that you are interested in the position and that you have taken the time to prepare for the interview. It also gives you an opportunity to learn more about the company and the position. Some good questions to ask the interviewer include:

- What are the biggest challenges facing the company right now?

- What are the most important qualities you are looking for in a candidate for this position?

- What is the company culture like?

- What are the opportunities for advancement within the company?

- What is the next step in the interview process?

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Dress professionally

- Arrive on time

5. Be confident and enthusiastic

Confidence and enthusiasm are contagious, so it is important to project these qualities during your interview. This will make you more likeable and memorable to the interviewer.

- Be confident

- Be enthusiastic

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Tie in Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.