Are you gearing up for a career in Tufting Creeler? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tufting Creeler and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

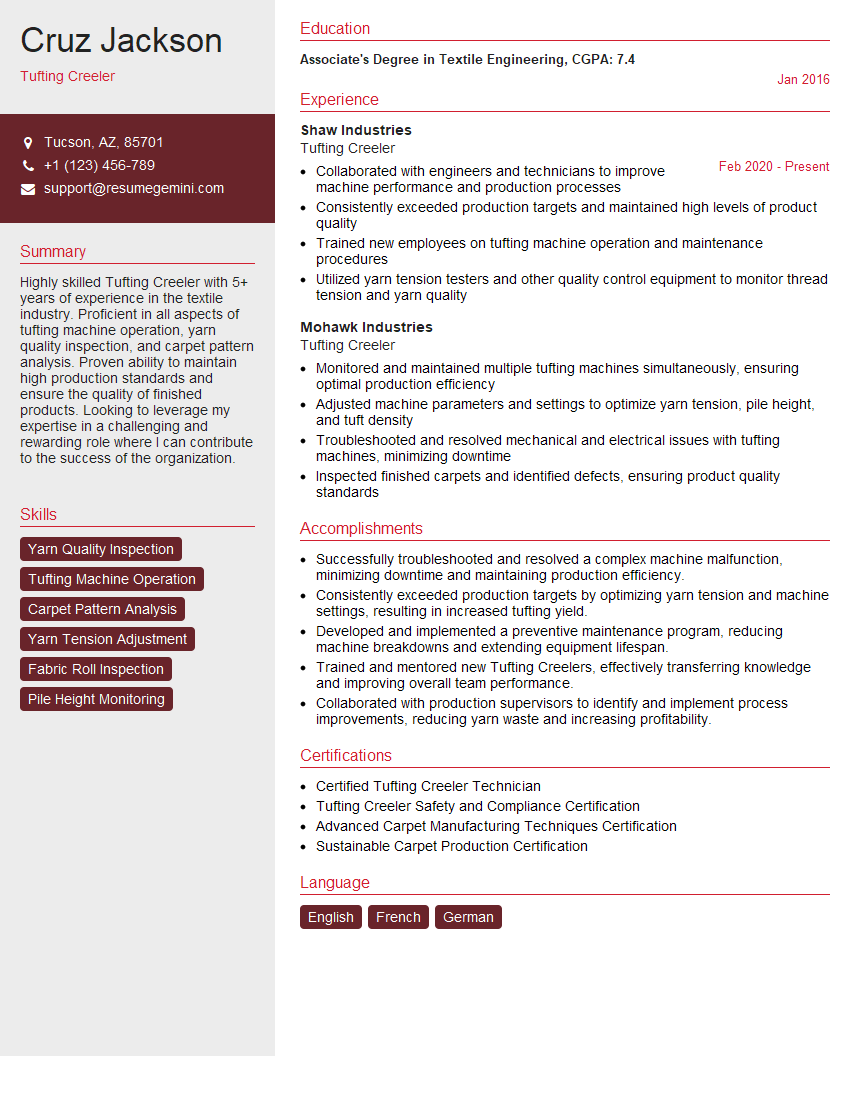

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tufting Creeler

1. What is the process of tufting?

Tufting is a textile manufacturing process that involves inserting loops of yarn or thread into a fabric backing to create a pile surface. This process can be done by hand or by machine.

2. What are the different types of tufting machines?

- Hand tufting machines

- Machine tufting machines

3. What are the different types of fabrics that can be used for tufting?

A variety of fabrics can be used for tufting, including:

- Cotton

- Wool

- Nylon

- Polyester

4. What are the different types of yarns that can be used for tufting?

A variety of yarns can be used for tufting, including:

- Acrylic

- Cotton

- Nylon

- Polyester

- Wool

5. What are the different pile heights that can be achieved with tufting?

The pile height of a tufted fabric is the length of the loops of yarn or thread that form the pile surface. The pile height can be varied depending on the type of tufting machine and the settings that are used.

6. What are the different applications for tufted fabrics?

Tufted fabrics are used in a variety of applications, including:

- Carpets

- Rugs

- Upholstery

- Wall coverings

- Clothing

- Accessories

7. What are the challenges of tufting?

Some of the challenges of tufting include:

- Keeping the loops of yarn or thread even and consistent

- Avoiding snags and other defects in the fabric

- Meeting the quality standards of the customer

8. What are the safety precautions that must be taken when tufting?

Some of the safety precautions that must be taken when tufting include:

- Wearing appropriate safety gear, such as gloves and eye protection

- Keeping the work area clean and free of tripping hazards

- Using the tufting machine properly and according to the manufacturer’s instructions

9. What are the troubleshooting tips for tufting?

Some of the troubleshooting tips for tufting include:

- If the loops of yarn or thread are not even or consistent, adjust the tension of the yarn or thread

- If there are snags or other defects in the fabric, stop the machine and remove the defect

- If the fabric is not meeting the quality standards of the customer, check the settings of the tufting machine and make adjustments as needed

10. What are the latest trends in tufting?

Some of the latest trends in tufting include:

- The use of new materials, such as recycled fibers and sustainable yarns

- The development of new tufting techniques, such as 3D tufting

- The use of tufting to create new and innovative products

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tufting Creeler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tufting Creeler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tufting Creeler is responsible for ensuring that the creel on a tufting machine is stocked with yarn and properly maintained.

1. Loading and Unloading Yarn

The creel holds the spools of yarn that are used to create the carpet. The Tufting Creeler is responsible for loading the creel with full spools of yarn and removing empty spools.

- Inspect yarn for any defects or damages before loading onto creel

- Properly thread yarn through tensioners and guides

2. Monitoring Yarn Tension

The Tufting Creeler must ensure that the yarn is properly tensioned as it passes through the creel. This is important for ensuring that the yarn is properly fed into the tufting machine and that the carpet is of good quality.

- Adjust tension knobs to maintain optimal yarn tension

- Identify and correct any yarn breaks or tension issues promptly

3. Inspecting Yarn and Creel

The Tufting Creeler must regularly inspect the yarn and creel for any signs of damage or wear. This is important for preventing yarn breaks and other problems that can affect the quality of the carpet.

- Visually examine yarn for any abnormalities, such as knots or fraying

- Check creel components for any signs of wear or damage, such as broken or bent guides

4. Maintaining Creel

The Tufting Creeler must perform regular maintenance on the creel to ensure that it is in good working order. This includes cleaning the creel, lubricating moving parts, and replacing worn components.

- Clean creel regularly to remove dust and debris

- Lubricate moving parts to minimize friction and wear

Interview Tips

Here are some interview tips and hacks to help you ace your interview for a Tufting Creeler position:

1. Research the Company and Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website to learn about its history, products, and services

- Read industry publications and articles to stay up-to-date on the latest trends and technologies in the field

2. Practice Your Answers

Once you have a good understanding of the company and the position, take some time to practice your answers to common interview questions. This will help you to feel more confident and prepared during your interview.

- Prepare answers to questions about your experience, skills, and qualifications

- Practice answering behavioral questions, such as “Tell me about a time when you had to overcome a challenge”

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the job you are applying for.

- Choose conservative colors and styles

- Avoid wearing clothing that is too revealing or distracting

4. Be On Time

Punctuality is important, so make sure to arrive for your interview on time. This shows the interviewer that you are respectful of their time and that you are serious about the job.

- Plan your route ahead of time and allow extra time for traffic or unexpected delays

- If you are running late, call or email the interviewer to let them know

Next Step:

Now that you’re armed with the knowledge of Tufting Creeler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tufting Creeler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini