Are you gearing up for a career in Winding Rack Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Winding Rack Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

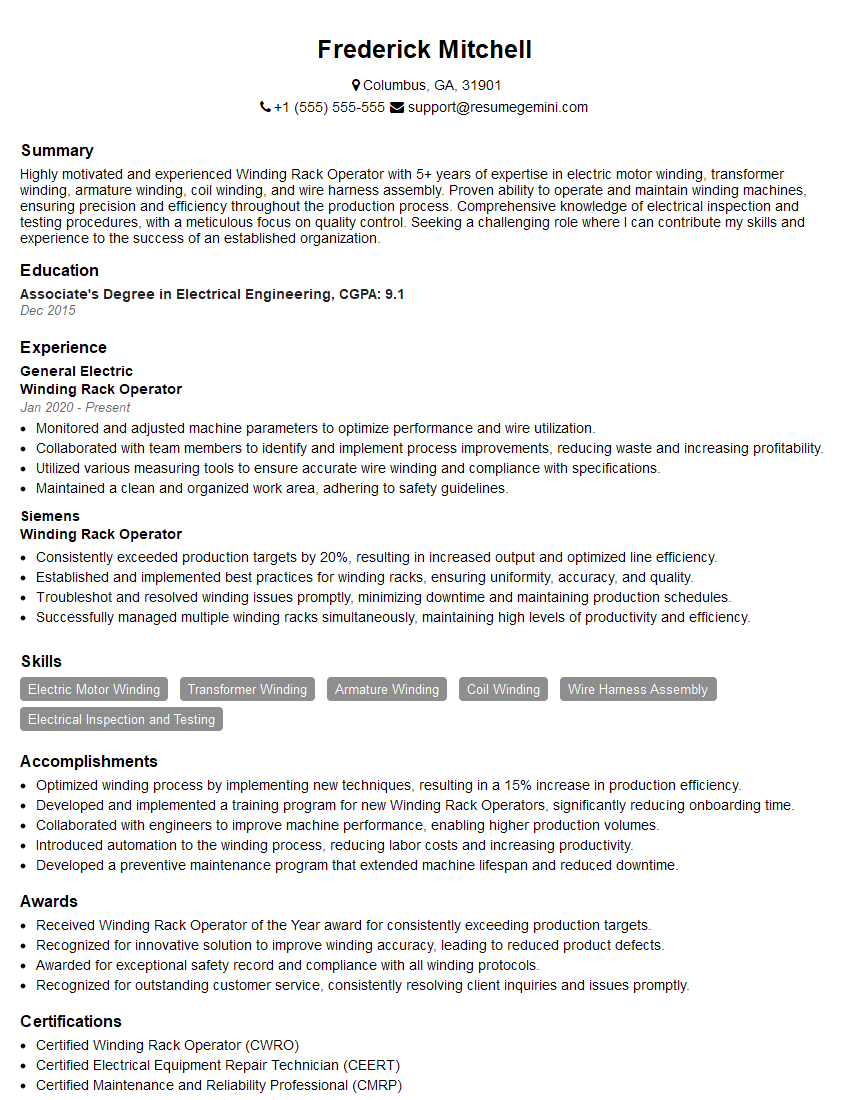

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Winding Rack Operator

1. Walk me through the process of loading yarn onto a winding rack?

Sample Answer:

– Inspect the yarn to ensure it meets the required specifications. – Determine the appropriate winding tension and speed based on yarn type and desired package size. – Mount the empty bobbins onto the winding machine. – Feed the yarn onto the bobbins, ensuring even tension and distribution. – Monitor the winding process to prevent any yarn breaks or tangles. – Regularly check the yarn tension and speed to maintain optimal winding conditions.2. How do you handle and resolve yarn breaks during winding?

Handling Yarn Breaks:

–Resolving Yarn Breaks:

–3. Describe the different types of winding machines you have operated and their capabilities?

Sample Answer:

–4. What is the importance of proper tension control during winding?

Sample Answer:

- Ensures uniform and consistent yarn package density.

- Prevents yarn breaks and tangles, reducing waste and downtime.

- Maintains yarn quality by preventing excessive stretching or damage.

- Optimizes downstream processes such as dyeing, weaving, and knitting.

- Improves the overall efficiency and product quality.

5. How do you maintain and calibrate winding machines to ensure optimal performance?

Sample Answer:

- Regularly clean and lubricate machine components to prevent wear and tear.

- Calibrate tension meters and speedometers to ensure accurate measurements.

- Check and adjust machine settings for different yarn types and package sizes.

- Identify and resolve any mechanical issues promptly to prevent breakdowns.

- Monitor machine performance and record data to track trends and identify potential problems.

6. Explain the quality standards and inspection procedures involved in winding yarn?

Sample Answer:

- Inspecting yarn for defects, contamination, and irregularities.

- Checking package size, tension, and surface quality against specifications.

- Using testing equipment to measure yarn thickness, strength, and density.

- Maintaining detailed records of inspection results and taking corrective actions as needed.

- Complying with industry standards and customer requirements.

7. What is the role of a Winding Rack Operator in a production environment?

Sample Answer:

- Loading, unloading, and monitoring winding machines.

- Maintaining optimal winding conditions to ensure yarn quality and efficiency.

- Identifying and resolving yarn breaks and winding issues promptly.

- Maintaining a clean and organized work area.

- Communicating with other team members and supervisors to ensure smooth operations.

8. Describe any safety protocols or precautions related to winding machine operation?

Sample Answer:

- Wearing appropriate safety gear, including gloves and safety glasses.

- Keeping hands away from moving machine parts.

- Following proper lockout/tagout procedures before performing maintenance.

- Reporting any safety concerns or hazards to supervisors immediately.

- Maintaining a clean and clutter-free work area to prevent tripping or entanglement.

9. How do you prioritize tasks and manage workload in a fast-paced production environment?

Sample Answer:

- Assessing task urgency and prioritizing based on customer orders and production deadlines.

- Planning and organizing tasks to maximize efficiency and minimize downtime.

- Communicating with team members to ensure coordination and avoid bottlenecks.

- Using visual aids, such as task lists or kanban boards, to track progress and identify potential issues.

- Seeking support from supervisors or colleagues when necessary to meet production goals.

10. What is your approach to continuous improvement and learning in your role?

Sample Answer:

- Regularly reviewing and analyzing winding processes to identify areas for improvement.

- Consulting with experienced operators or engineers to gain new insights and best practices.

- Participating in training programs and workshops to enhance knowledge and skills.

- Seeking feedback from supervisors and colleagues to identify areas for growth.

- Staying updated with industry advancements and new technologies related to winding.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Winding Rack Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Winding Rack Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Winding Rack Operator is responsible for maintaining and operating the winding rack equipment at a manufacturing facility to produce wire spools efficiently and safely. Their primary duties involve loading and unloading wire onto the winding rack, ensuring proper tension and alignment, and monitoring the operation for any issues.

1. Equipment Operation and Maintenance

- Operate the winding rack equipment, including the winding head, traversing carriage, and tension control system.

- Perform routine maintenance and cleaning of the equipment to ensure optimal performance and prevent breakdowns.

- Troubleshoot and resolve minor equipment issues as needed.

2. Wire Handling and Management

- Load wire onto the winding rack from designated locations.

- Ensure proper tension and alignment of the wire during the winding process.

- Unload finished wire spools and prepare them for storage or further processing.

3. Quality Control and Monitoring

- Monitor the winding process to ensure adherence to specifications and quality standards.

- Inspect finished wire spools for defects and ensure compliance with customer requirements.

- Maintain detailed records and logs of winding parameters and production output.

4. Safety and Environmental Compliance

- Adhere to all safety regulations and guidelines to prevent accidents and injuries.

- Maintain a clean and organized work area, adhering to environmental regulations.

- Dispose of waste and hazardous materials appropriately.

Interview Tips

To prepare for a successful interview as a Winding Rack Operator, it is crucial to highlight your technical skills, attention to detail, and commitment to safety. Here are some tips to enhance your performance:

1. Research the Company and Position

- Visit the company’s website to learn about their products, services, and industry reputation.

- Read the job description thoroughly and identify the key responsibilities and qualifications required.

2. Showcase Your Technical Expertise

- Emphasize your experience in operating winding rack equipment, including the different types of wire and winding techniques.

- Provide specific examples of how you have maintained and repaired winding machines, demonstrating your troubleshooting abilities.

3. Highlight Your Attention to Detail

- Stress your ability to work precisely and accurately, ensuring proper tension and alignment of the wire during winding.

- Explain how you maintain detailed records and consistently meet quality standards.

4. Emphasize Your Safety Consciousness

- Demonstrate your understanding of safety protocols and regulations for operating winding rack equipment.

- Describe your experience in maintaining a clean and organized work area to prevent accidents.

5. Prepare for Common Interview Questions

- Practice answering questions about your experience with different types of winding machines and wire materials.

- Be prepared to describe your approach to troubleshooting equipment issues and maintaining production output.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Winding Rack Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.