Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Blown Film Extrusion Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Blown Film Extrusion Operator so you can tailor your answers to impress potential employers.

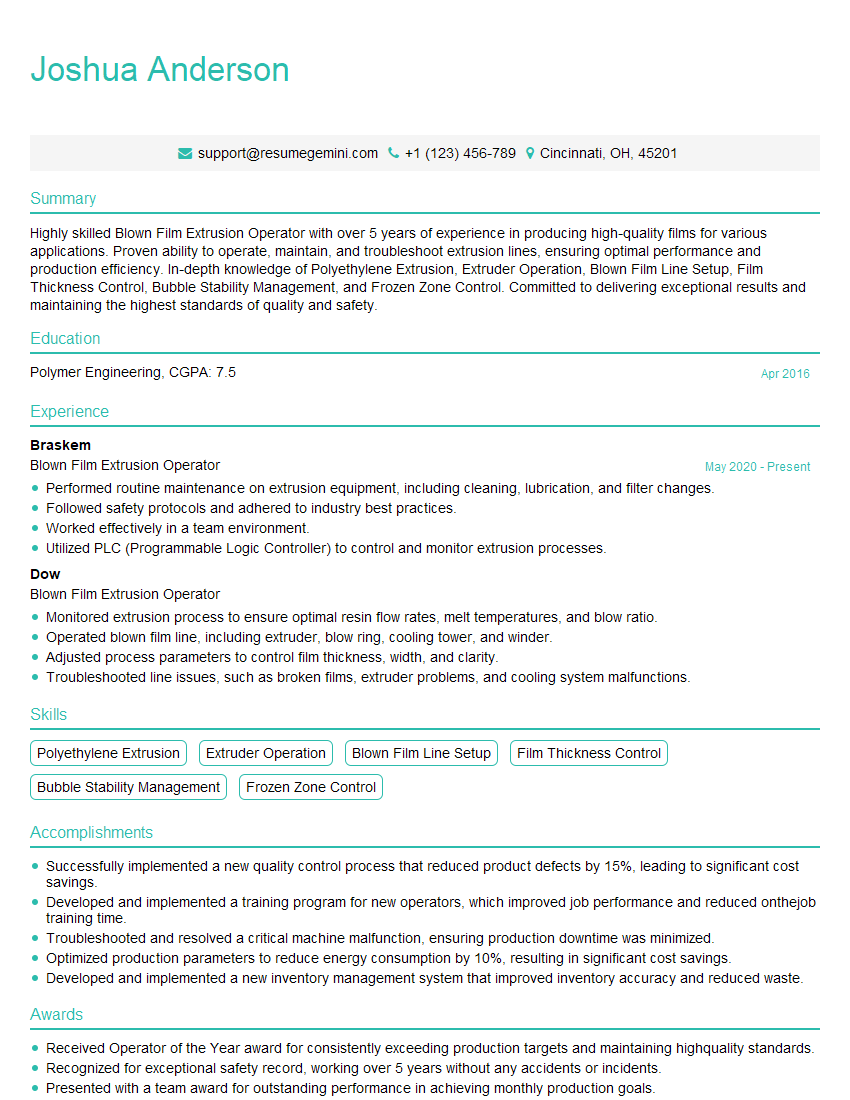

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blown Film Extrusion Operator

1. What are the key responsibilities of a Blown Film Extrusion Operator?

As a Blown Film Extrusion Operator, my key responsibilities include:

- Monitoring and operating blown film extrusion lines to produce high-quality plastic film

- Setting up and adjusting extrusion equipment, including dies, extruders, and winders

- Controlling process parameters such as temperature, pressure, and speed to ensure optimal film properties

- Inspecting and testing film for defects and maintaining production records

- Troubleshooting and resolving process issues to minimize downtime

- Maintaining a clean and safe work environment

2. Describe the different types of blown film extrusion processes and their applications?

Cast Film Extrusion:

- Produces thin, flat film with high clarity and gloss

- Used in packaging, printing, and labeling applications

Blown Film Extrusion:

- Produces thicker, more durable film with good strength and flexibility

- Used in packaging, bags, and agricultural applications

Coextrusion:

- Produces film with multiple layers of different materials

- Used to combine properties such as barrier resistance, strength, and printability

3. What are the critical quality control parameters in blown film extrusion?

Critical quality control parameters in blown film extrusion include:

- Film thickness and uniformity

- Tensile strength and elongation

- Optical properties (clarity, gloss, haze)

- Barrier properties (moisture, oxygen, aroma)

- Sealability and printability

4. How do you troubleshoot common problems in blown film extrusion, such as film breaks, bubbles, and gels?

Troubleshooting common problems in blown film extrusion involves:

- Identifying the root cause of the problem through process monitoring and analysis

- Adjusting process parameters such as temperature, pressure, or speed

- Inspecting equipment for wear or damage

- Cleaning or replacing equipment components as necessary

- Implementing preventive maintenance measures to minimize downtime

5. What are the safety precautions that must be followed when operating blown film extrusion equipment?

Safety precautions for blown film extrusion equipment operation include:

- Wearing appropriate personal protective equipment (PPE)

- Following lockout/tagout procedures

- Maintaining a clean and organized work area

- Being aware of potential hazards such as hot surfaces, moving machinery, and electrical equipment

- Reporting any accidents or near misses immediately

6. How do you ensure that the blown film produced meets the customer’s specifications?

To ensure that the blown film meets customer specifications, I:

- Review customer specifications thoroughly

- Monitor and control process parameters to meet the required film properties

- Perform regular quality control tests on the film

- Make necessary adjustments to the process based on test results

- Document all production records and maintain traceability

7. What are the latest advancements in blown film extrusion technology that you are aware of?

Some recent advancements in blown film extrusion technology include:

- Automated process control systems to improve efficiency and consistency

- Multilayer coextrusion lines for producing films with enhanced properties

- Biodegradable and sustainable film materials to reduce environmental impact

- Inline film measurement and monitoring systems to ensure product quality

8. What is the role of a Blown Film Extrusion Operator in a lean manufacturing environment?

In a lean manufacturing environment, the Blown Film Extrusion Operator plays a vital role in:

- Identifying and eliminating waste in the production process

- Improving efficiency and reducing cycle times

- Maximizing equipment utilization

- Implementing continuous improvement initiatives

- Collaborating with other team members to achieve production goals

9. How do you stay updated on the latest best practices and industry trends in blown film extrusion?

To stay updated on the latest best practices and industry trends in blown film extrusion, I:

- Attend industry conferences and workshops

- Read trade publications and technical journals

- Network with other professionals in the field

- Participate in online forums and discussion groups

10. What is your approach to resolving conflicts or issues with colleagues or supervisors?

My approach to resolving conflicts or issues with colleagues or supervisors is to:

- Communicate openly and respectfully

- Listen to different perspectives and try to understand the underlying causes

- Identify common ground and work towards a mutually acceptable solution

- Remain professional and avoid making personal attacks

- Seek guidance from a higher authority or HR if necessary

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blown Film Extrusion Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blown Film Extrusion Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Blown film extrusion operators are responsible for the operation of blown film extrusion lines, which produce plastic film for use in a variety of applications. Their key responsibilities include:

1. Operating Blown Film Extrusion Lines

Operators are responsible for starting up, shutting down, and operating blown film extrusion lines, ensuring that they are running smoothly and efficiently.

- Monitoring line parameters and making adjustments as needed

- Loading and unloading material

- Troubleshooting and repairing line equipment

2. Quality Control

Operators are responsible for maintaining product quality, ensuring that the film meets specifications.

- Inspecting film for defects

- Making adjustments to the extrusion process as needed

- Maintaining records of product quality

3. Safety

Operators are responsible for ensuring the safety of themselves and others in the workplace.

- Following safety procedures

- Using personal protective equipment

- Reporting any unsafe conditions

4. Other Responsibilities

In addition to the responsibilities listed above, operators may also be required to:

- Clean and maintain extrusion equipment

- Assist with production planning

- Train new operators

Interview Tips

To ace the interview for a Blown Film Extrusion Operator position, it is important to be prepared. Here are some tips to help you prepare:

1. Research the Company and the Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, goals, and the expectations for the position.

- Visit the company’s website

- Read industry publications

- Talk to people who work or have worked for the company

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Why do you want to work for this company?” and “What are your strengths and weaknesses?”. It is important to practice your answers to these questions so that you can deliver them confidently and clearly.

- Use the STAR method to answer questions (Situation, Task, Action, Result)

- Tailor your answers to the specific position and company

- Be honest and authentic in your answers

3. Be Prepared to Talk About Your Experience

In addition to answering common interview questions, you should also be prepared to talk about your experience and skills. This is your chance to highlight your qualifications for the position and show the interviewer why you are the best person for the job.

- Quantify your accomplishments whenever possible

- Use specific examples to illustrate your skills

- Be enthusiastic and positive about your experience

4. Ask Questions

At the end of the interview, be sure to ask the interviewer questions. This shows that you are interested in the position and that you are eager to learn more about the company. Some good questions to ask include:

- What are the biggest challenges facing the company?

- What are the opportunities for advancement?

- What is the company culture like?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Blown Film Extrusion Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!