Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fiberglass Dowel Drawing Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

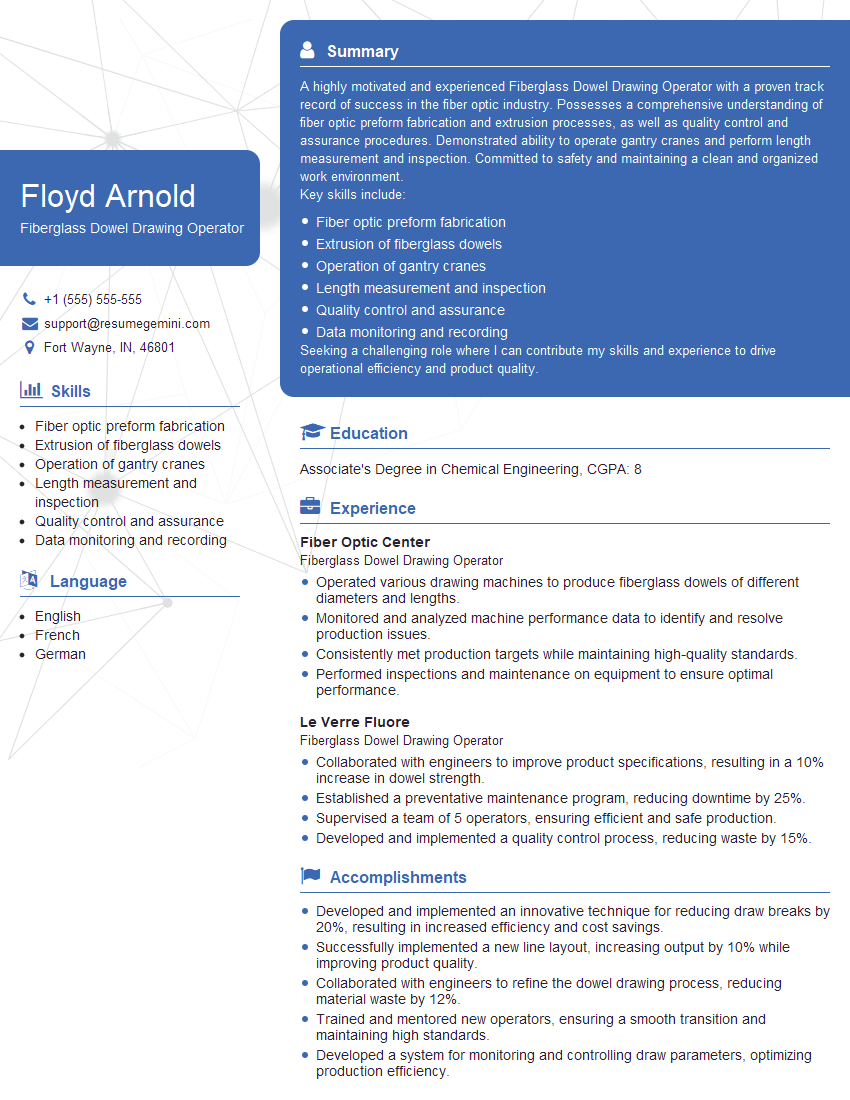

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fiberglass Dowel Drawing Operator

1. Explain the key steps involved in the fiberglass dowel drawing process?

The key steps involved in the fiberglass dowel drawing process are:

- Preheating: The fiberglass roving is heated to a high temperature to soften it and make it more pliable.

- Drawing: The softened roving is pulled through a series of dies to reduce its diameter and increase its strength.

- Cooling: The drawn dowel is cooled to room temperature to set its shape and properties.

- Finishing: The dowel may be subjected to additional processes such as grinding, polishing, or coating to meet specific requirements.

2. What are the critical process parameters that need to be controlled during fiberglass dowel drawing?

Viscosity:

- The viscosity of the glass melt must be carefully controlled to ensure the desired flow properties.

- Viscosity affects the ability of the glass to be drawn into a continuous fiber.

Temperature:

- The temperature of the glass melt must be precisely controlled to achieve the desired viscosity and fiber properties.

- Temperature variations can lead to defects in the fibers or inconsistent properties.

Draw speed:

- The speed at which the glass is drawn must be carefully controlled to ensure the desired fiber diameter and strength.

- Draw speed affects the stress and strain on the fiber during drawing.

3. How do you ensure the quality of the fiberglass dowel?

To ensure the quality of the fiberglass dowel, I follow several key steps:

- Raw material inspection: I inspect incoming fiberglass roving for any defects or inconsistencies.

- Process monitoring: I closely monitor the drawing process and make adjustments as needed to maintain optimal parameters.

- Regular testing: I perform regular tests on the drawn dowel to assess its diameter, strength, and other properties.

- Documentation and recordkeeping: I maintain detailed records of all process parameters and test results for quality control purposes.

4. Describe the common defects that can occur during fiberglass dowel drawing and how to prevent them?

Some common defects that can occur during fiberglass dowel drawing include:

- Breakage: This can occur due to excessive stress on the fiber during drawing.

- Surface defects: These can be caused by impurities in the glass melt or uneven cooling.

- Diameter variations: This can occur due to inconsistencies in the drawing process or the temperature of the glass melt.

- Strength variations: This can occur due to variations in the fiber diameter or the quality of the glass melt.

To prevent these defects, I ensure that the drawing process parameters are carefully controlled and that the equipment is properly maintained.

5. What are the safety precautions that need to be taken when working with fiberglass?

When working with fiberglass, it is important to take the following safety precautions:

- Wear protective clothing: This includes gloves, long sleeves, pants, and a respirator to protect from fiberglass dust.

- Avoid contact with skin: Fiberglass can cause skin irritation and itching.

- Use proper ventilation: Fiberglass dust can be harmful if inhaled.

- Dispose of fiberglass waste properly: Fiberglass waste should be disposed of in designated containers to prevent environmental contamination.

6. How do you troubleshoot common problems that may arise during fiberglass dowel drawing?

To troubleshoot common problems that may arise during fiberglass dowel drawing, I follow these steps:

- Identify the problem: Determine the specific defect or issue that is occurring.

- Review process parameters: Check if any of the process parameters, such as temperature, draw speed, or viscosity, are out of range.

- Inspect equipment: Examine the drawing equipment for any signs of wear or damage.

- Analyze test results: Review the results of any tests performed on the dowel to identify any inconsistencies.

- Make adjustments: Based on the analysis, make necessary adjustments to the process parameters or equipment to resolve the issue.

7. How do you maintain and calibrate the equipment used in fiberglass dowel drawing?

To maintain and calibrate the equipment used in fiberglass dowel drawing, I perform the following tasks:

- Regular cleaning and inspection: Regularly clean and inspect the equipment to remove any fiberglass dust or debris that could affect its operation.

- Calibration: Calibrate the equipment according to the manufacturer’s instructions to ensure accurate measurements and control.

- Preventive maintenance: Perform preventive maintenance tasks, such as lubrication and replacement of worn parts, to keep the equipment in good working condition.

- Operator training: Train operators on proper equipment use and maintenance procedures to prevent errors.

8. What is the importance of teamwork in the fiberglass dowel drawing process?

Teamwork is essential in the fiberglass dowel drawing process for the following reasons:

- Safety: Working with fiberglass can be hazardous, and teamwork helps ensure that all safety protocols are followed.

- Efficiency: By working together, operators can optimize the drawing process and improve productivity.

- Problem-solving: When problems arise, a team can collaborate to identify and resolve them quickly.

- Knowledge sharing: Team members can share their knowledge and experience to improve the overall process.

9. How do you stay updated on the latest advancements in fiberglass dowel drawing technology?

To stay updated on the latest advancements in fiberglass dowel drawing technology, I take the following steps:

- Attend industry conferences and workshops: This allows me to learn about new technologies and best practices.

- Read technical journals and publications: I stay informed about the latest research and developments in the field.

- Network with other professionals: I connect with other fiberglass dowel drawing operators and experts to exchange knowledge and ideas.

- Participate in training programs: I attend training programs offered by equipment manufacturers or industry organizations to enhance my skills.

10. How do you handle stress and pressure in a demanding work environment?

To handle stress and pressure in a demanding work environment, I employ the following strategies:

- Time management: I prioritize my tasks and allocate my time effectively to avoid feeling overwhelmed.

- Delegation: When possible, I delegate tasks to others to lighten my workload and free up my time for more critical tasks.

- Communication: I communicate openly with my colleagues and supervisors to keep them informed of my progress and any challenges I may be facing.

- Self-care: I prioritize my physical and mental health by getting enough sleep, eating healthy foods, and exercising regularly.

- Positive mindset: I try to maintain a positive attitude even during challenging times and focus on finding solutions rather than dwelling on problems.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fiberglass Dowel Drawing Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fiberglass Dowel Drawing Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fiberglass Dowel Drawing Operators are professionals who manufacture fiberglass dowels and tubes by drawing molten fiberglass material through a mold or orifice. Their key job responsibilities involve:

1. Fiberglass Manufacturing

Operate fiberglass dowel drawing machines to produce dowels and tubes of varying diameters and lengths.

- Prepare and set up dowel drawing equipment, including molds, dies, and nozzles.

- Monitor and control the temperature, pressure, and speed of the drawing process to ensure product quality.

2. Inspection and Quality Control

Inspect and test the finished fiberglass dowels and tubes to verify dimensional accuracy and physical properties.

- Perform dimensional measurements, visual inspection, and strength testing.

- Maintain records and document the inspection results.

3. Process Optimization

Identify and implement process improvements to enhance efficiency and product quality.

- Analyze production data, identify bottlenecks, and develop solutions.

- Suggest modifications to equipment or processes to increase productivity.

4. Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting of fiberglass dowel drawing equipment.

- Clean and lubricate equipment to prevent breakdowns.

- Identify and resolve mechanical or operational issues.

- Coordinate with maintenance personnel for major repairs.

Interview Tips

To ace an interview for a Fiberglass Dowel Drawing Operator position, candidates should:

1. Research the Company and Position

Thoroughly research the company’s fiberglass manufacturing operations and the specific role of a Fiberglass Dowel Drawing Operator. This will enable you to articulate how your skills and experience align with their requirements.

- Visit the company’s website, read about their products and services, and familiarize yourself with their industry.

- Review the job description carefully to understand the key responsibilities and qualifications.

2. Highlight Relevant Experience and Skills

Emphasize your hands-on experience in fiberglass manufacturing, including dowel drawing, inspection, and process optimization. Quantify your accomplishments using specific examples to demonstrate your impact.

- Describe the types of fiberglass dowels and tubes you have produced, the equipment you have operated, and the quality standards you have maintained.

- Highlight any experience in troubleshooting and resolving equipment issues.

3. Demonstrate Quality Orientation

Fiberglass Dowel Drawing Operators must be highly quality-oriented. Provide examples of your attention to detail, focus on accuracy, and commitment to continuous improvement.

- Explain your approach to quality control and inspection procedures.

- Discuss any certifications or training you have obtained in quality management.

4. Show Enthusiasm and Willingness to Learn

Express your passion for fiberglass manufacturing and your eagerness to learn new techniques and technologies. Show that you are willing to stay updated on industry best practices.

- Inquire about the company’s research and development efforts in fiberglass manufacturing.

- Ask questions about opportunities for professional growth and training.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fiberglass Dowel Drawing Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.