Feeling lost in a sea of interview questions? Landed that dream interview for Synthetic Staple Extruder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Synthetic Staple Extruder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

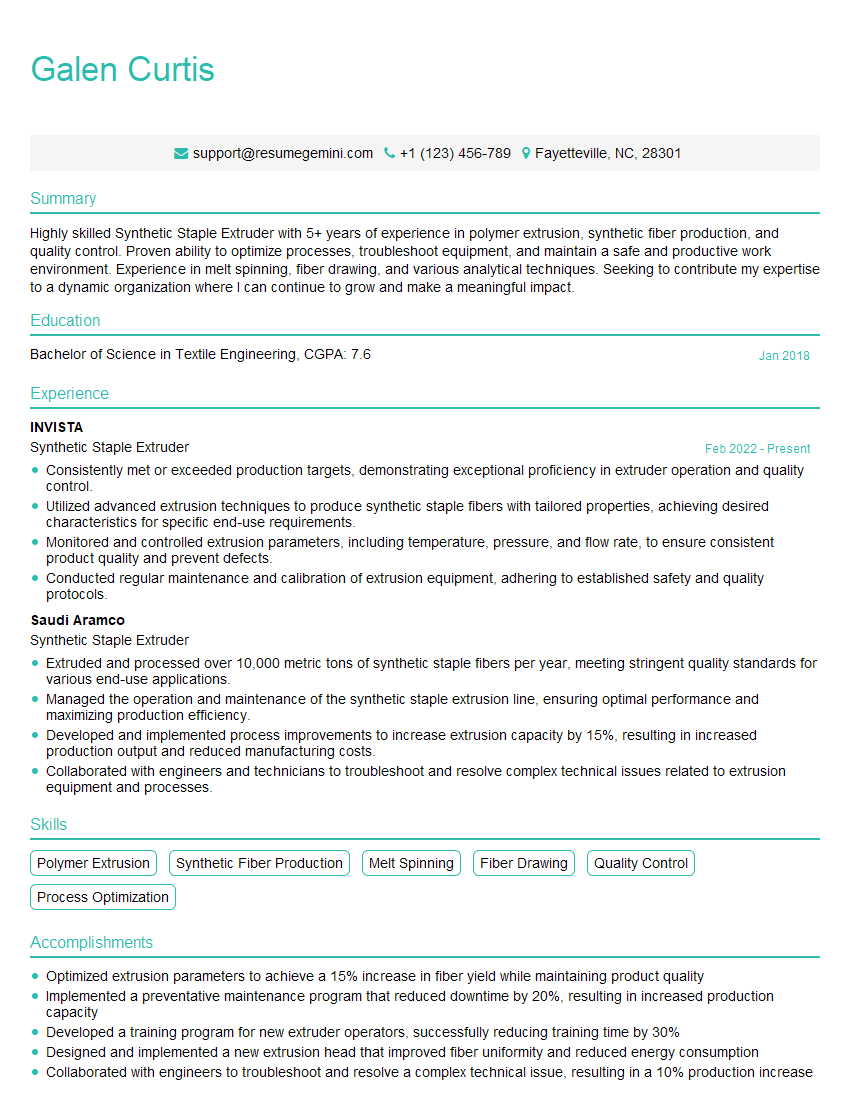

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Synthetic Staple Extruder

1. Describe the process of synthetic staple extrusion in detail.

- Explain the preparation of raw materials.

- Explain the process of polymer melt extrusion.

- Describe the formation of staple fibers.

2. Discuss the factors that affect the quality of synthetic staples.

Raw Material Factors

- Polymer grade and molecular weight

- Additives and modifiers

Process Factors

- Extrusion temperature and pressure

- Spinning speed and draw ratio

- Cooling conditions

3. Explain how the melt flow index (MFI) of the polymer affects the extrusion process and fiber properties.

MFI is a measure of the polymer’s flowability. A higher MFI indicates a lower melt viscosity, which allows for easier extrusion. However, it can also lead to weaker fibers with lower tenacity and modulus. Conversely, a lower MFI indicates a higher melt viscosity, which can make extrusion more difficult but can result in stronger fibers.

4. Describe the different types of spinning systems used in synthetic staple extrusion and their advantages and disadvantages.

- Wet spinning: Advantages- high fiber strength, good dyeability; Disadvantages- high water consumption, environmental concerns.

- Dry spinning: Advantages- lower energy consumption, less environmental impact; Disadvantages- lower fiber strength, more brittle.

- Melt spinning: Advantages- high productivity, versatility; Disadvantages- lower fiber strength than wet spinning.

5. Explain the importance of quenching in the synthetic staple extrusion process.

- Rapidly cools the extruded fibers, preventing crystallization.

- Locks in the desired fiber structure and properties.

- Improves fiber strength and tenacity.

6. Describe the different quality control checks performed during synthetic staple extrusion.

- Raw material analysis

- Polymer melt properties testing

- Fiber diameter and uniformity measurements

- Tenacity and elongation testing

- Visual inspection for defects

7. Explain the role of additives in synthetic staple extrusion.

- Antioxidants: Prevent polymer degradation during extrusion.

- Lubricants: Reduce friction and improve fiber flow.

- Antistatic agents: Prevent fiber clumping.

- Flame retardants: Enhance fire resistance.

8. Describe the different applications of synthetic staples.

- Textile industry: Yarns, fabrics, nonwovens

- Automotive industry: Seat covers, carpets

- Medical industry: Surgical gowns, bandages

- Geotextiles: Soil reinforcement, erosion control

9. Explain how the use of recycled materials in synthetic staple extrusion can contribute to sustainability.

- Reduces waste and landfill disposal.

- Conserves virgin resources.

- Lowers energy consumption and greenhouse gas emissions.

10. Discuss the challenges and opportunities in the synthetic staple extrusion industry.

Challenges

- Fluctuating raw material prices.

- Environmental regulations.

- Intense competition.

Opportunities

- Growing demand for synthetic fibers in various applications.

- Technological advancements in extrusion processes.

- Increased emphasis on sustainability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Synthetic Staple Extruder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Synthetic Staple Extruder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Synthetic Staple Extruder is a skilled professional responsible for operating and maintaining extrusion machines used to produce synthetic staple fibers. These fibers are widely used in the textile industry to create various fabrics and products.

1. Machine Operation and Maintenance

Operate and monitor extrusion machines, ensuring they run efficiently and produce consistent fiber quality.

- Control machine settings, including temperature, pressure, and feed rate

- Monitor machine performance and make necessary adjustments to optimize production

- Perform routine maintenance tasks, such as cleaning, lubrication, and minor repairs

2. Quality Control

Monitor fiber quality throughout the production process and make adjustments as needed.

- Conduct regular inspections of fibers to ensure they meet specifications

- Analyze fiber samples using testing equipment to verify properties such as strength, fineness, and color

- Identify and resolve any quality issues promptly

3. Process Optimization

Continuously improve the extrusion process to enhance efficiency and productivity.

- Analyze production data and identify areas for improvement

- Experiment with different process parameters to optimize fiber quality and machine performance

- Implement process changes and monitor their impact

4. Safety and Environmental Compliance

Adhere to all safety regulations and environmental standards.

- Wear appropriate safety gear and follow established safety procedures

- Monitor environmental emissions and take steps to minimize their impact

- Dispose of waste materials and byproducts responsibly

Interview Tips

To ace an interview for a Synthetic Staple Extruder position, consider the following preparation tips and strategies.

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. This knowledge will help you understand their business needs and tailor your answers accordingly.

2. Practice Common Interview Questions

Prepare for typical interview questions related to your skills, experience, and motivations. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and highlight your accomplishments.

3. Showcase Your Technical Expertise

Demonstrate your knowledge of extrusion processes, fiber properties, and quality control techniques. Be prepared to discuss how you have optimized production and resolved technical issues in the past.

4. Emphasize Safety and Environmental Awareness

Highlight your commitment to safety and environmental compliance. Explain your understanding of relevant regulations and how you ensure the safe operation of extrusion machines and minimize environmental impact.

5. Highlight Your Problem-Solving and Analytical Skills

Give examples of how you have identified and solved problems during the extrusion process. Emphasize your ability to analyze data, draw conclusions, and implement effective solutions.

6. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your interest in the position and the company. Prepare questions about the specific role, the company’s future plans, and opportunities for professional development.

Next Step:

Now that you’re armed with the knowledge of Synthetic Staple Extruder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Synthetic Staple Extruder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini