Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Batcher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

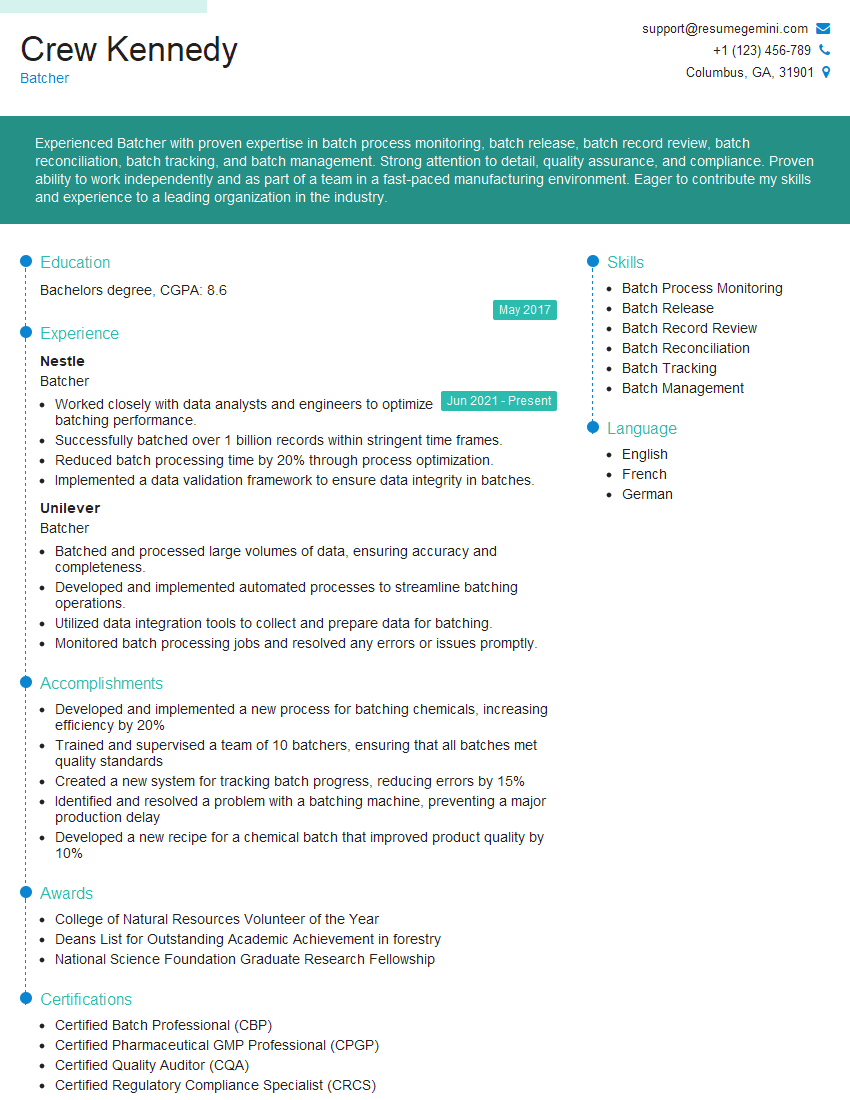

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Batcher

1. Describe the key responsibilities of a Batcher?

- Preparing and loading batch records in a timely and accurate manner

- Monitoring and maintaining equipment used in batching materials

- Ensuring the safety of the work area and compliance with all health and safety regulations

- Maintaining a clean and organized work area

- Working effectively as part of a team

- Following instructions and procedures accurately

- Reporting any problems or concerns to the supervisor

2. What are the qualities of a successful Batcher?

- Strong attention to detail

- Ability to work independently and as part of a team

- Physical stamina and ability to stand for long periods of time

- Ability to work in a noisy and dusty environment

- Good communication and interpersonal skills

- Commitment to safety

3. What are the different types of batching processes?

- Manual batching

- Semi-automatic batching

- Automatic batching

4. What are the advantages and disadvantages of each type of batching process?

Advantages and disadvantages of manual batching

- Advantages:

- Low initial cost

- Easy to operate

- Flexible

- Disadvantages:

- Slow and labor-intensive

- Inaccurate

- Not suitable for large-scale production

Advantages and disadvantages of semi-automatic batching

- Advantages:

- Faster and more accurate than manual batching

- Less labor-intensive

- Suitable for small- to medium-scale production

- Disadvantages:

- Higher initial cost than manual batching

- Not as flexible as manual batching

Advantages and disadvantages of automatic batching

- Advantages:

- Fastest and most accurate batching process

- Least labor-intensive

- Suitable for large-scale production

- Disadvantages:

- Highest initial cost

- Least flexible

5. What are the key factors to consider when selecting a batching process?

- The type of material being batched

- The required batch size

- The desired accuracy

- The available budget

- The available space

- The required level of automation

- The availability of skilled labor

6. What are the common problems that can occur during batching and how can they be prevented?

- Inaccurate weighing or measuring of ingredients

- Contamination of materials

- Equipment malfunction

- Human error

Preventing inaccurate weighing or measuring of ingredients

- Use calibrated scales and measuring devices

- Double-check measurements

- Train operators on proper weighing and measuring procedures

Preventing contamination of materials

- Store materials in clean and dry containers

- Use clean equipment

- Follow good manufacturing practices

Preventing equipment malfunction

- Regularly maintain and inspect equipment

- Follow manufacturer’s instructions

- Train operators on proper equipment use

Preventing human error

- Provide clear and concise instructions

- Train operators on proper procedures

- Establish a quality control system

7. What are the safety precautions that should be taken when working with batching equipment?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a dust mask

- Be aware of the location of emergency stop buttons and pull cords

- Do not operate equipment that is not in good working order

- Never put your hands or body parts near moving machinery

- Keep the work area clean and free of debris

- Follow all safety instructions provided by the manufacturer

8. What are the environmental regulations that apply to batching operations?

- The Clean Air Act

- The Clean Water Act

- The Resource Conservation and Recovery Act

- The Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA)

- The Occupational Safety and Health Act (OSHA)

9. What are the industry trends in batching technology?

- Increased automation

- Improved accuracy

- Reduced costs

- Increased sustainability

10. What are the career opportunities for Batchers?

- Batcher Supervisor

- Production Manager

- Quality Control Manager

- Sales Representative

- Technical Support

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Batcher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Batcher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Batcher plays a crucial role in managing production processes within various industries. Their key responsibilities involve:

1. Batch Creation and Management

Batchers establish and manage production batches, ensuring adherence to specifications and quality standards.

- Determine batch size and composition based on production plans.

- Assign materials and resources to each batch, maintaining accurate inventory records.

- Monitor batch progress, identifying potential issues and implementing corrective actions.

2. Production Scheduling and Optimization

Batchers coordinate and optimize production schedules to maximize efficiency and minimize downtime.

- Develop production plans and allocate resources to meet deadlines.

- Identify and resolve bottlenecks, streamlining processes and reducing waste.

- Maintain communication with production staff to ensure smooth operations.

3. Quality Control and Assurance

Batchers ensure adherence to quality standards throughout the production process.

- Conduct quality checks and inspections at various stages of production.

- Analyze data and identify areas for improvement, implementing corrective actions.

- Maintain documentation and records related to quality standards and compliance.

4. Logistics and Distribution

Batchers manage the logistics and distribution of finished products.

- Coordinate with logistics providers to ensure timely delivery of products.

- Manage inventory levels and track shipments, preventing shortages or overstocking.

- Resolve logistics issues and ensure smooth flow of goods to customers.

Interview Tips

To ace your Batcher interview, preparation is key. Here are some tips to help you succeed:

1. Research the Company and Industry

Demonstrate your interest and knowledge by researching the company and the industry they operate in. Understand their products, processes, and the specific role you are applying for.

- Visit the company website and social media pages.

- Read industry publications and articles to stay up-to-date on trends.

2. Highlight Your Relevant Skills and Experience

Tailor your resume and cover letter to emphasize your skills and experience that are relevant to the Batcher role. Quantify your accomplishments using specific metrics whenever possible.

- Showcase your expertise in batch creation, production scheduling, quality control, and logistics.

- Provide examples of how you have optimized processes, reduced waste, and ensured product quality.

3. Practice Answering Common Interview Questions

Prepare for common interview questions related to batch processing, production management, quality assurance, and problem-solving. Practice your answers to demonstrate your knowledge and confidence.

- Describe your experience in creating and managing production batches.

- Explain how you would optimize a production schedule to reduce downtime.

- Provide an example of a quality issue you encountered and how you resolved it.

4. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions that demonstrate your interest and engagement. This shows the interviewer that you are genuinely interested in the role and the company.

- Inquire about the company’s growth plans and future projects.

- Ask about the specific challenges and opportunities that come with the Batcher role.

5. Follow Up and Express Gratitude

Send a thank-you email to the interviewer within 24 hours of the interview. Express your appreciation for their time and consideration. Reiterate your interest in the role and highlight any additional information that may support your application.

Remember, confidence is key during the interview. By practicing these tips and demonstrating your skills and passion for batch processing, you can increase your chances of impressing the interviewer and securing the Batcher position.Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Batcher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!