Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bead Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

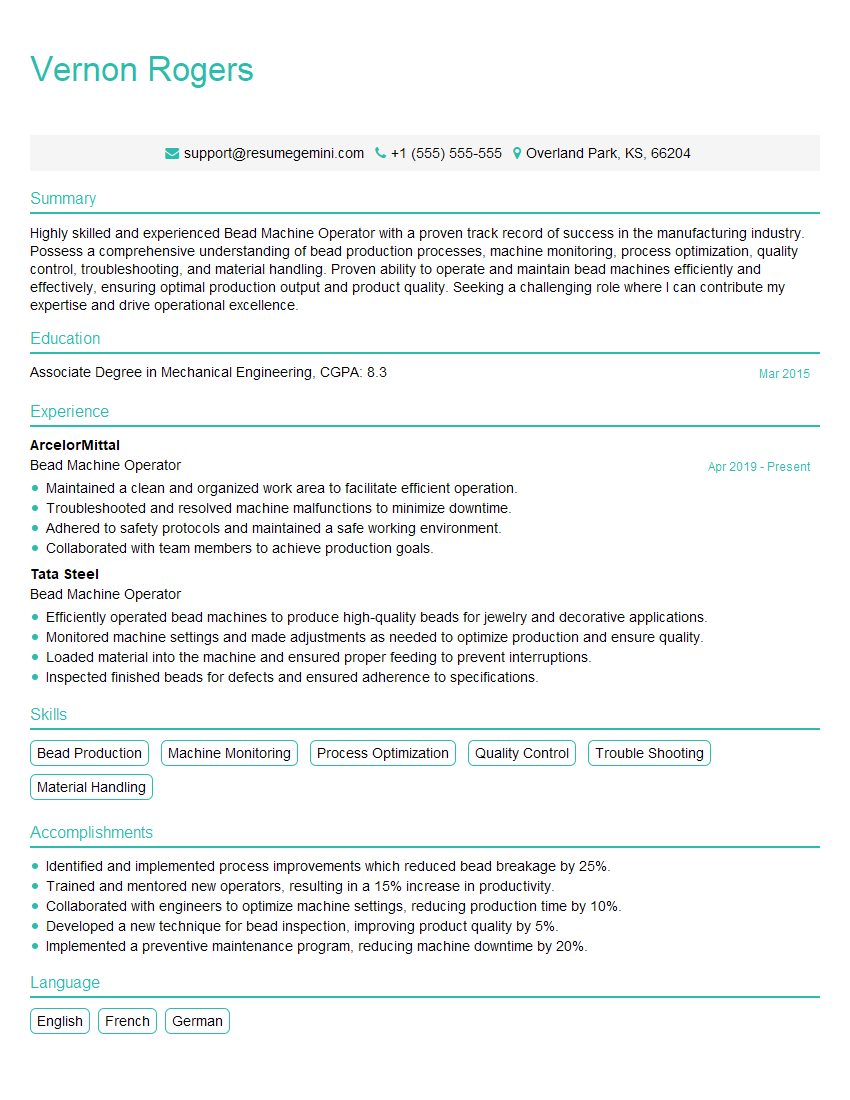

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bead Machine Operator

1. What are the key responsibilities of a Bead Machine Operator?

As a Bead Machine Operator, I am responsible for the efficient operation of bead forming machines. My key duties include:

- Setting up and operating bead forming machines according to specifications.

- Monitoring the production process and making adjustments as needed to ensure quality and productivity.

- Inspecting finished beads for defects and ensuring they meet customer requirements.

- Maintaining the bead forming machines to ensure optimal performance and minimize downtime.

- Following safety protocols and adhering to established procedures.

2. Describe the different types of bead forming machines you have experience with.

CNC Bead Forming Machines:

- Proficient in programming and operating CNC bead forming machines.

- Experienced in creating complex bead forms using CAD/CAM software.

- Skilled in optimizing machine parameters for efficient production.

Manual Bead Forming Machines:

- Thorough understanding of manual bead forming techniques.

- Expertise in using various bead forming tools and equipment.

- Ability to produce accurate and consistent beads manually.

3. What is your approach to troubleshooting and resolving production issues?

When troubleshooting production issues, I follow a systematic approach:

- Identify the problem: Analyze the situation and symptoms to determine the root cause.

- Investigate possible causes: Consider various factors that may have contributed to the issue, such as machine settings, material properties, or operator error.

- Develop a solution: Based on my analysis, I propose and implement a solution to resolve the issue.

- Test and verify: Conduct tests to ensure the solution effectively addresses the problem.

- Document the findings: Record the issue, solution, and any necessary adjustments for future reference.

4. What are the critical quality control measures you implement in your bead forming process?

To ensure the production of high-quality beads, I implement the following quality control measures:

- Inspection of raw materials: Verify that the incoming materials meet specifications before using them in production.

- Machine calibration: Calibrate bead forming machines regularly to maintain precision and accuracy.

- In-process inspections: Conduct inspections throughout the production process to identify and correct any deviations.

- Final product inspection: Perform thorough inspections of finished beads against established quality standards.

- Data collection and analysis: Monitor production data to identify trends and areas for improvement.

5. How do you handle high-volume production targets while maintaining quality standards?

To meet high-volume production targets while ensuring quality standards, I employ the following strategies:

- Process optimization: Continuously evaluate and improve the production process to increase efficiency and minimize waste.

- Preventive maintenance: Regularly inspect and maintain bead forming machines to prevent breakdowns and ensure optimal performance.

- Team coordination: Collaborate with production and quality control teams to ensure smooth workflow and timely issue resolution.

- Training and development: Provide ongoing training to operators to enhance their skills and knowledge.

- Quality control documentation: Maintain detailed records of quality control inspections and corrective actions taken.

6. What is your experience in working with different materials in bead forming?

I have extensive experience in working with various materials in bead forming, including:

- Metals: Steel, aluminum, copper, and brass.

- Plastics: ABS, PVC, and polycarbonate.

- Wood: Hardwoods and softwoods.

- Glass: Annealed and tempered glass.

For each material, I understand its specific properties and adjust my bead forming techniques accordingly to achieve optimal results.

7. How do you ensure the safety of yourself and others while operating bead forming machines?

Safety is a top priority in my work. I adhere to the following measures to ensure a safe work environment:

- Proper attire: Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Machine guarding: Ensure that all machine guards are in place and functioning correctly.

- Safe work practices: Follow established safety procedures, such as lockout/tagout and proper tool usage.

- Emergency preparedness: Familiarize myself with emergency procedures and evacuation routes.

- Hazard identification: Identify potential hazards in the workplace and take steps to minimize risks.

8. What is your experience in using specialized bead forming techniques?

In addition to standard bead forming techniques, I am proficient in the following specialized techniques:

- Wire bending: Creating complex shapes and designs using wire bending machines.

- Hydroforming: Using high-pressure water to form beads in metal sheets.

- Bead rolling: Using a bead roller to create decorative or functional beads on metal surfaces.

- Laser cutting: Utilizing laser technology to cut intricate bead shapes in various materials.

9. How do you stay up-to-date with the latest advancements in bead forming technology?

To stay current with the latest advancements, I engage in the following activities:

- Industry publications: Read trade magazines and journals to keep abreast of new techniques and equipment.

- Conferences and exhibitions: Attend industry events to network with experts and learn about innovative technologies.

- Online resources: Utilize online forums and webinars to connect with other professionals and gain knowledge.

- Manufacturer training: Participate in training programs offered by bead forming machine manufacturers.

- Research and development: Conduct my own research and explore new approaches to improve bead forming processes.

10. What is your approach to continuous improvement in your role as a Bead Machine Operator?

Continuous improvement is essential in my role. I follow these steps to enhance my skills and the production process:

- Identify areas for improvement: Regularly evaluate current practices and seek opportunities for optimization.

- Research and explore: Investigate new technologies, techniques, and best practices that can improve efficiency or quality.

- Implement and test changes: Introduce small-scale changes and monitor their impact on the production process.

- Document and share: Record successful improvements and share them with colleagues to foster a culture of continuous improvement.

- Seek feedback: Regularly solicit feedback from supervisors, colleagues, and customers to identify areas for further growth.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bead Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bead Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bead Machine Operators are responsible for operating and maintaining bead-making machines. They work in a variety of settings, including manufacturing plants, warehouses, and construction sites. Their primary duties include:

1. Machine Operation

Bead Machine Operators are responsible for the safe and efficient operation of bead-making machines. They must be able to follow instructions, read blueprints, and make adjustments to the machine as needed.

- Loading raw materials into the machine

- Monitoring the machine’s operation

- Making adjustments to the machine as needed

2. Machine Maintenance

Bead Machine Operators are also responsible for the maintenance of bead-making machines. They must be able to identify and resolve common problems, and they must be able to perform basic maintenance tasks, such as cleaning and lubrication.

- Cleaning and lubricating the machine

- Inspecting the machine for damage

- Replacing worn or damaged parts

3. Quality Control

Bead Machine Operators are responsible for ensuring that the beads produced by the machine meet quality standards. They must be able to inspect beads for defects, and they must be able to make adjustments to the machine as needed to correct any problems.

- Inspecting beads for defects

- Making adjustments to the machine to correct any problems

- Ensuring that the beads meet quality standards

4. Safety

Bead Machine Operators must always follow safety procedures when operating and maintaining bead-making machines. They must be aware of the potential hazards associated with the machine, and they must take steps to avoid accidents.

- Following safety procedures when operating and maintaining the machine

- Wearing appropriate safety gear

- Keeping the work area clean and organized

Interview Tips

In order to ace your interview for a Bead Machine Operator position, it is important to be prepared. Here are a few tips:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job. You can find information about the company on their website, in their annual report, or in articles about the company in the news.

- Visit the company’s website

- Read the company’s annual report

- Read articles about the company in the news

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Tell me about yourself

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Be prepared to talk about your experience

In your interview, you will be asked about your experience operating and maintaining bead-making machines. Be prepared to talk about your specific responsibilities, and be sure to highlight any skills or experience that are relevant to the position you are applying for.

- Talk about your experience operating and maintaining bead-making machines

- Highlight any skills or experience that are relevant to the position you are applying for

- Be prepared to answer questions about your experience

4. Be enthusiastic and positive

Employers are looking for candidates who are enthusiastic and positive about their work. In your interview, be sure to convey your passion for operating and maintaining bead-making machines. Let the interviewer know that you are excited about the opportunity to work for the company and that you are confident that you have the skills and experience to be successful in the position.

- Be enthusiastic and positive about your work

- Convey your passion for operating and maintaining bead-making machines

- Let the interviewer know that you are excited about the opportunity to work for the company

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bead Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.