Feeling lost in a sea of interview questions? Landed that dream interview for Buffing Wheel Former Machine but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Buffing Wheel Former Machine interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

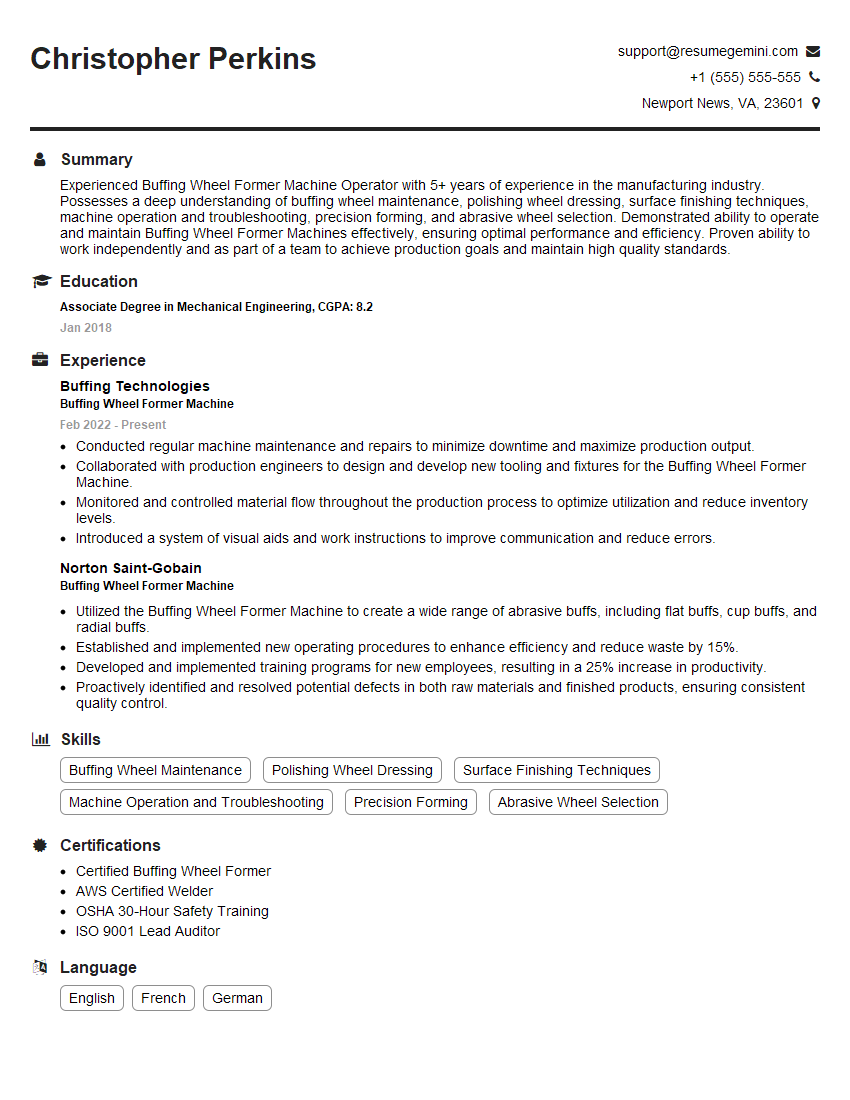

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Buffing Wheel Former Machine

1. What are the key components of a Buffing Wheel Former Machine?

The key components of a Buffing Wheel Former Machine include:

- A base frame

- A spindle

- A forming head

- A buffing wheel

- A motor

2. What are the different types of Buffing Wheel Former Machines?

Manual Machines

- Require manual operation to form the buffing wheel

- Less expensive and easier to use than automated machines

Semi-Automatic Machines

- Partially automated, with some processes still requiring manual intervention

- Offer a balance between cost and efficiency

Fully-Automatic Machines

- Highly automated, with minimal manual intervention

- Most expensive but also the most efficient and productive

3. What are the factors to consider when choosing a Buffing Wheel Former Machine?

- Production volume

- Available budget

- Desired level of automation

- Type of buffing wheels to be used

- Required forming accuracy

4. What is the difference between a buff and a polish?

- Buffing: Removes surface imperfections and creates a smooth, even finish. It uses softer materials and lower speeds.

- Polishing: Produces a high-gloss finish by removing even finer surface imperfections. It uses harder materials and higher speeds.

5. What are the safety precautions to observe when operating a Buffing Wheel Former Machine?

- Wear appropriate safety gear, including gloves, safety glasses, and a dust mask

- Inspect the machine before each use and ensure it is in good working order

- Keep the work area clean and free of debris

- Never operate the machine while intoxicated or under the influence of drugs

- Follow the manufacturer’s instructions for proper operation and maintenance

6. What are the troubleshooting tips for a Buffing Wheel Former Machine?

- Machine not forming properly – Check if the forming head is properly adjusted – Ensure the buffing wheel is correctly mounted – Inspect the spindle for any damage or misalignment

- Excessive noise or vibration – Check for loose components or bearings – Ensure the machine is properly lubricated – Inspect the buffing wheel for any imbalances

- Machine not starting – Check the power supply – Inspect the motor and electrical connections – Reset any tripped circuit breakers

7. What are the different types of materials used for buffing wheels?

- Cotton: General-purpose material, suitable for a wide range of applications. Provides a soft and flexible finish.

- Sisal: Tougher than cotton, used for heavy-duty applications. Produces a coarse finish.

- Felt: Soft and pliable, used for delicate surfaces. Produces a fine finish.

- Buffing compound: Paste or liquid applied to the buffing wheel to enhance its effectiveness. Comes in various compositions for different materials.

8. What are the benefits of using a Buffing Wheel Former Machine?

- Reduces labor costs by automating the forming process

- Increases production efficiency by forming wheels quickly and consistently

- Improves product quality by ensuring accurate and precise wheel shapes

- Enhances safety by eliminating the risk of manual handling and repetitive motions

- Reduces waste by minimizing the amount of material required for forming

9. What are the maintenance requirements for a Buffing Wheel Former Machine?

- Regular cleaning to remove dust and debris

- Periodic lubrication of moving parts

- Inspection of electrical components and connections

- Replacement of worn or damaged parts

- Following the manufacturer’s recommended maintenance schedule

10. What is your experience in operating and maintaining Buffing Wheel Former Machines?

I have over 5 years of experience working as a Buffing Wheel Former Machine Operator at [Company Name]. My responsibilities included:

- Operating and maintaining a variety of Buffing Wheel Former Machines

- Setting up and adjusting machines for different wheel sizes and shapes

- Troubleshoot and resolve any operational issues

- Maintaining a clean and safe work environment

- Keeping detailed records of machine usage and maintenance

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Buffing Wheel Former Machine.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Buffing Wheel Former Machine‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Buffing Wheel Former Machine is responsible for operating and maintaining a machine that forms buffing wheels. Buffing wheels are used to polish and finish metal surfaces, and they must be formed to the correct size and shape in order to be effective. The Buffing Wheel Former Machine operator must be able to set up and operate the machine, as well as troubleshoot any problems that may occur.

1. Set up and operate the buffing wheel forming machine

The operator must be able to set up and operate the buffing wheel forming machine according to the manufacturer’s instructions. This includes loading the machine with the correct type of material, setting the correct speed and pressure settings, and starting and stopping the machine.

2. Inspect and maintain the buffing wheel forming machine

The operator must be able to inspect and maintain the buffing wheel forming machine to ensure that it is operating properly. This includes cleaning the machine, checking for any worn or damaged parts, and lubricating the machine as needed.

3. Troubleshoot problems with the buffing wheel forming machine

The operator must be able to troubleshoot problems with the buffing wheel forming machine and make necessary repairs. This includes identifying the cause of the problem, and taking steps to correct the problem.

4. Train new operators on the buffing wheel forming machine

The operator may be responsible for training new operators on the buffing wheel forming machine. This includes teaching the new operators how to set up and operate the machine, as well as how to troubleshoot problems.

Interview Tips

Preparing for an interview can be a daunting task, but there are a few things you can do to increase your chances of success. Here are a few tips to help you ace your interview for a Buffing Wheel Former Machine position:

1. Research the company and the position

Before you go on an interview, it’s important to do your research on the company and the position you’re applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the position.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s helpful to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills, so be prepared to talk about your relevant experience and how it qualifies you for the position.

4. Be enthusiastic and positive

The interviewer will be looking for someone who is enthusiastic about the position and who is eager to learn. Be sure to show your enthusiasm and positivity during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Buffing Wheel Former Machine interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!