Feeling lost in a sea of interview questions? Landed that dream interview for Dielectric Embossing Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Dielectric Embossing Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

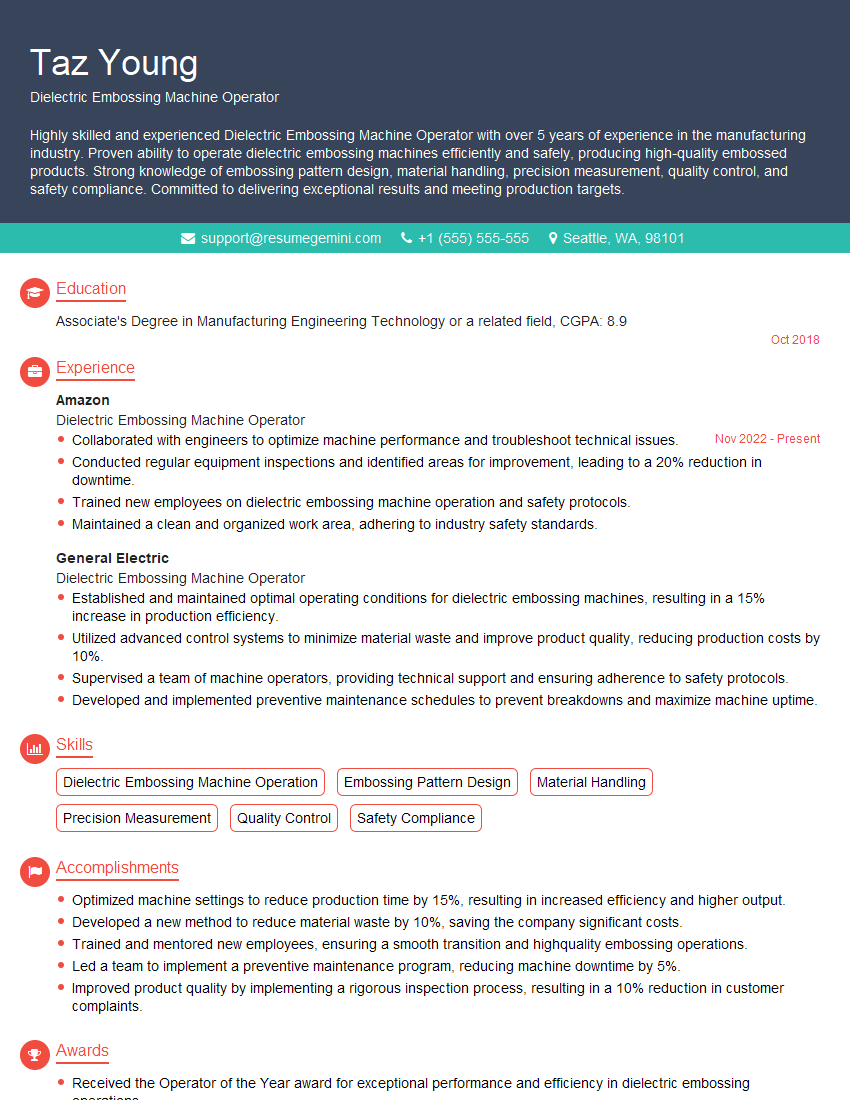

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dielectric Embossing Machine Operator

1. Explain the working principle of a dielectric embossing machine?

A dielectric embossing machine uses a high-frequency electric field to create raised or recessed patterns on the surface of a dielectric material. The process involves the following steps:

- A dielectric material is placed between two electrodes.

- A high-frequency electric field is applied across the electrodes, creating an electric field within the dielectric material.

- The electric field causes the dielectric material to become polarized, resulting in the alignment of the molecules in the material.

- The aligned molecules create a stress gradient within the dielectric material, which causes the material to deform.

- The deformation creates raised or recessed patterns on the surface of the dielectric material.

2. What are the different types of dielectric materials that can be embossed?

- Polyimide

- Polyethylene

- Polypropylene

- Polycarbonate

- Polyester

- PTFE

- FEP

- PFA

3. What are the critical parameters that need to be controlled during the dielectric embossing process?

- Electric field strength

- Frequency of the electric field

- Temperature of the dielectric material

- Pressure applied to the dielectric material

4. What are the different applications of dielectric embossing?

- Electronics

- Medical devices

- Automotive

- Packaging

5. What are the safety precautions that need to be taken when operating a dielectric embossing machine?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a lab coat.

- Ensure that the machine is properly grounded.

- Do not touch any of the electrical components of the machine.

- Keep the work area clean and free of debris.

- Follow all of the manufacturer’s instructions for operating the machine.

6. What are the common problems that can occur during the dielectric embossing process and how can they be troubleshooting?

- Problem: The embossed pattern is not clear or sharp.

- Troubleshooting:

- Increase the electric field strength.

- Increase the frequency of the electric field.

- Increase the temperature of the dielectric material.

- Increase the pressure applied to the dielectric material.

- Problem: The embossed pattern is too deep or too shallow.

- Troubleshooting:

- Decrease the electric field strength.

- Decrease the frequency of the electric field.

- Decrease the temperature of the dielectric material.

- Decrease the pressure applied to the dielectric material.

- Problem: The embossed pattern is not uniform.

- Troubleshooting:

- Ensure that the dielectric material is evenly heated.

- Ensure that the pressure applied to the dielectric material is uniform.

- Check the alignment of the electrodes.

7. What are the maintenance requirements for a dielectric embossing machine?

- Regularly clean the machine, including the electrodes, the work area, and the surrounding area.

- Inspect the electrical components of the machine for any damage or wear.

- Lubricate the machine’s moving parts.

- Calibrate the machine regularly to ensure that it is operating correctly.

8. What are the skills and experience required to be a successful dielectric embossing machine operator?

- Knowledge of the dielectric embossing process

- Experience operating a dielectric embossing machine

- Ability to read and understand technical drawings

- Ability to troubleshoot and repair minor problems

- Good communication and interpersonal skills

9. What are the career advancement opportunities for a dielectric embossing machine operator?

- Dielectric embossing machine supervisor

- Process engineer

- Quality control manager

10. Why are you interested in working as a dielectric embossing machine operator?

I am interested in working as a dielectric embossing machine operator because I am fascinated by the process of creating raised or recessed patterns on the surface of a dielectric material. I am also eager to learn more about the different applications of dielectric embossing and how it can be used to create innovative products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dielectric Embossing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dielectric Embossing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dielectric Embossing Machine Operators are responsible for operating and maintaining dielectric embossing machines, which produce embossed patterns on plastic or paper products. Their key job responsibilities include:

1. Machine Operation

Loading and unloading materials into the machine

- Setting up and adjusting the machine to produce the desired embossing pattern

- Monitoring the machine’s operation and making adjustments as needed

2. Product Inspection

Inspecting finished products for quality and accuracy

- Identifying and correcting any defects

- Ensuring that products meet specifications

3. Machine Maintenance

Performing routine maintenance on the machine

- Cleaning and lubricating parts

- Replacing worn or damaged parts

4. Safety Compliance

Following all safety protocols and procedures

- Wearing appropriate safety gear

- Operating the machine in a safe manner

Interview Tips

To ace an interview for a Dielectric Embossing Machine Operator position, candidates should follow these tips:

1. Research the Company and Position

Learn about the company’s history, products, and values.

- Research the specific job requirements and responsibilities.

- Come to the interview with a clear understanding of the role and how your skills and experience align with the company’s needs.

2. Highlight Relevant Skills and Experience

Emphasize your experience operating and maintaining dielectric embossing machines.

- Provide specific examples of how you have used your skills to solve problems and improve efficiency.

- Highlight your attention to detail and commitment to quality.

3. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivation.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide concrete examples.

- Be able to articulate why you are interested in the position and why you are the best candidate for the job.

4. Be Enthusiastic and Professional

Show your enthusiasm for the position and the company.

- Maintain a positive attitude and be respectful of the interviewer.

- Dress appropriately and arrive on time for your interview.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Dielectric Embossing Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Dielectric Embossing Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.