Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Gripper Installer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Gripper Installer so you can tailor your answers to impress potential employers.

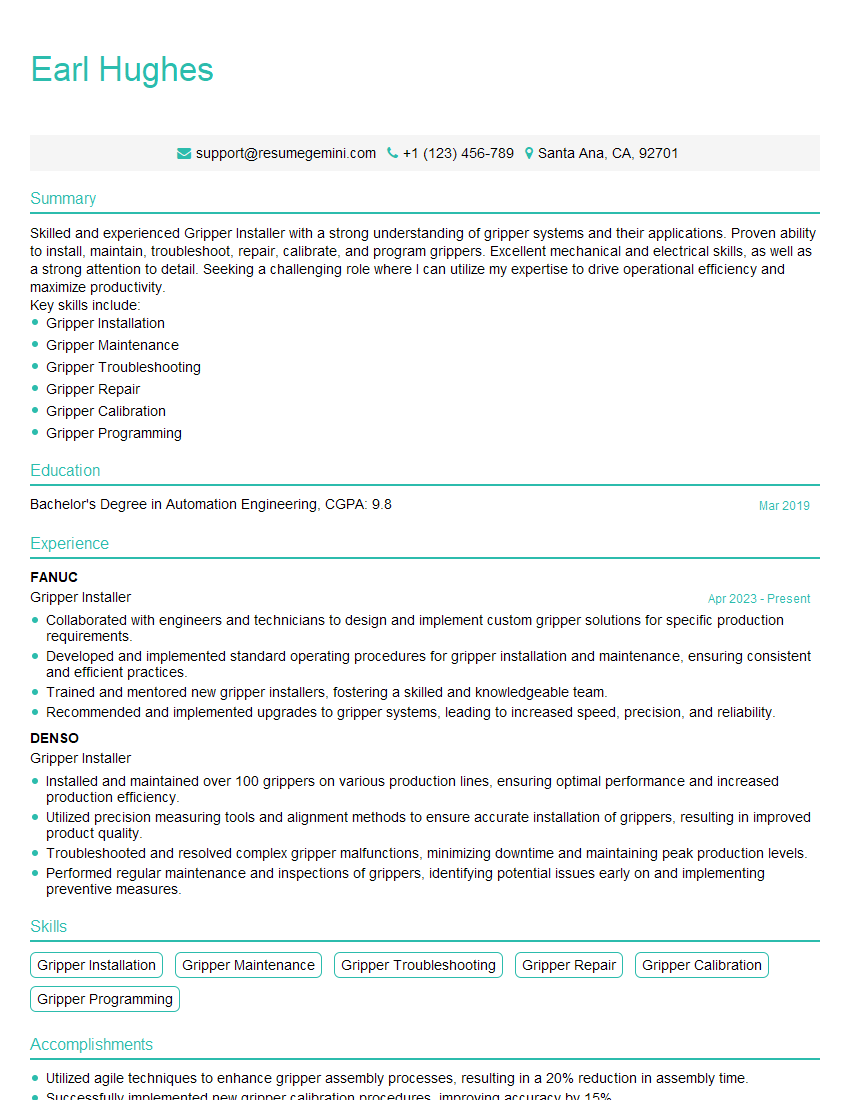

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gripper Installer

1. What are the different types of grippers used in manufacturing processes?

- Mechanical grippers use mechanical force to grasp and hold objects.

- Pneumatic grippers use compressed air to power their movement.

- Hydraulic grippers use hydraulic fluid to power their movement.

- Vacuum grippers use suction to hold objects.

- Magnetic grippers use magnets to hold ferrous objects.

2. What are the important factors to consider when selecting a gripper for a particular application?

subheading of the answer

- The size and shape of the object being gripped.

- The weight of the object being gripped.

- The required gripping force.

- The speed at which the object needs to be gripped.

- The environment in which the gripper will be used.

subheading of the answer

- The cost of the gripper.

- The availability of the gripper.

- The reputation of the gripper manufacturer.

3. What are the common problems that can occur with grippers and how can they be prevented?

- Grippers can become worn or damaged over time, which can affect their performance.

- Grippers can become contaminated with dirt or debris, which can also affect their performance.

- Grippers can be improperly installed, which can lead to problems.

4. What are the different types of gripper controls?

- Manual gripper controls are operated by hand.

- Pneumatic gripper controls are operated by compressed air.

- Hydraulic gripper controls are operated by hydraulic fluid.

- Electric gripper controls are operated by electricity.

5. What are the advantages and disadvantages of using pneumatic grippers?

- Advantages of using pneumatic grippers include their low cost, light weight, and ease of use.

- Disadvantages of using pneumatic grippers include their limited gripping force, their susceptibility to contamination, and their noise.

6. What are the advantages and disadvantages of using hydraulic grippers?

- Advantages of using hydraulic grippers include their high gripping force, their ability to operate in harsh environments, and their relatively long service life.

- Disadvantages of using hydraulic grippers include their high cost, their weight, and their complexity.

7. What are the advantages and disadvantages of using electric grippers?

- Advantages of using electric grippers include their high gripping force, their ability to operate in harsh environments, and their relatively long service life.

- Disadvantages of using electric grippers include their high cost, their weight, and their complexity.

8. What are the safety considerations when working with grippers?

- Grippers can be dangerous if they are not used properly.

- Grippers should always be inspected before use to make sure that they are in good working condition.

- Grippers should never be used to lift or move people.

- Grippers should never be used in areas where there is a risk of electrical shock.

9. What are the latest trends in gripper technology?

- The latest trends in gripper technology include the development of new materials, new designs, and new control systems.

- New materials are being developed that are lighter, stronger, and more durable than traditional materials.

- New designs are being developed that are more compact, more efficient, and more versatile than traditional designs.

- New control systems are being developed that are more sophisticated, more user-friendly, and more reliable than traditional control systems.

10. What are the different types of gripper fingers?

- There are many different types of gripper fingers, each with its own advantages and disadvantages.

- Some of the most common types of gripper fingers include:

- Parallel fingers

- Angular fingers

- Conical fingers

- Cup fingers

- Friction fingers

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gripper Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gripper Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Gripper Installer, you will be responsible for the installation, maintenance, and repair of grippers used in various industrial settings. Your key responsibilities will include:

1. Installation and Setup

Conduct site surveys to assess installation requirements for grippers in manufacturing and assembly lines.

- Assemble and install grippers according to blueprints and specifications.

- Configure and calibrate grippers to optimize performance and accuracy.

2. Troubleshooting and Maintenance

Diagnose and resolve operational issues with grippers, including electrical, pneumatic, and mechanical problems.

- Perform preventive maintenance tasks to ensure the smooth operation of grippers.

- Replace worn or damaged components to maintain optimal performance.

3. Safety and Compliance

Adhere to all safety protocols and regulations related to the installation and operation of grippers.

- Ensure that grippers are installed in a manner that minimizes potential hazards.

- Train operators on the proper use and maintenance of grippers.

4. Collaboration and Communication

Collaborate with engineers, electricians, and other technicians to ensure successful installation and operation of grippers.

- Communicate with customers to understand their needs and provide technical support.

- Document installation procedures and maintenance records for future reference.

Interview Tips

To ace your interview for a Gripper Installer position, consider the following tips:

1. Research the Company and Role

Thoroughly research the company and the specific requirements of the Gripper Installer role.

- Understand the company’s industry, products, and values.

- Review the job description carefully and identify the key skills and experience required.

2. Showcase Your Technical Skills

Highlight your technical proficiency in installing, maintaining, and troubleshooting grippers.

- Provide specific examples of complex installations or repairs you have handled.

- Discuss your understanding of gripper mechanics, electrical systems, and pneumatics.

3. Emphasize Safety and Compliance

Demonstrate your commitment to safety and compliance in your work.

- Explain your knowledge of relevant safety regulations and industry standards.

- Share examples of how you ensure the safe operation of grippers in your previous roles.

4. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses.

- For example, you may be asked about your experience with different types of grippers, your troubleshooting process, or your approach to working in a team.

- Prepare STAR (Situation, Task, Action, Result) stories to illustrate your skills and experience.

5. Ask Insightful Questions

Ask thoughtful questions at the end of the interview to show your interest and engagement.

- Inquire about the company’s plans for future gripper installations or upgrades.

- Ask about the opportunities for professional development and career growth within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gripper Installer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.