Feeling lost in a sea of interview questions? Landed that dream interview for Gripper Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Gripper Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

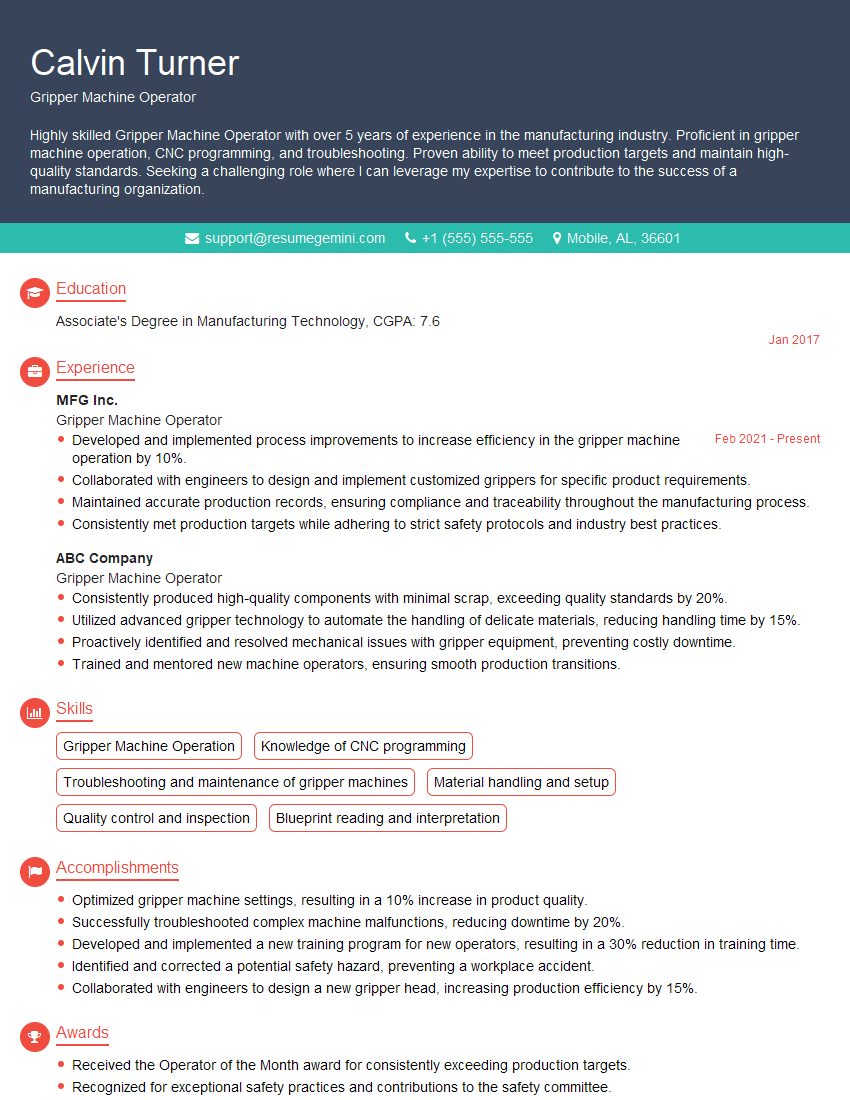

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gripper Machine Operator

1. What do you understand about a gripper machine, and how does it operate?

- A gripper machine is an automated device used in various industries to grip, manipulate, and move objects.

- It consists of two or more jaws or fingers that open and close to grasp or release objects.

- The jaws are usually powered by pneumatic or hydraulic cylinders and controlled by PLC or CNC systems.

- Gripper machines can be programmed to perform specific movements and sequences, making them suitable for repetitive and precise tasks.

2. Explain the different types of grippers and their applications?

- Parallel grippers: Have jaws that move parallel to each other, suitable for gripping flat objects or objects with parallel surfaces.

- Angular grippers: Have jaws that move in an angular or rotating motion, used for gripping cylindrical or irregular-shaped objects.

- Vacuum grippers: Use vacuum suction to grip objects, ideal for delicate or porous surfaces.

- Magnetic grippers: Use magnetic force to grip ferrous objects, useful for handling heavy or metallic objects.

3. What are the key factors to consider when selecting a gripper for a specific application?

- Object size and shape: Gripper jaws should be compatible with the object’s dimensions and geometry.

- Object weight and fragility: Grip force and jaw design must be appropriate to safely handle the object.

- Application requirements: Consider the precision, speed, and cycle time required for the task.

- Environment: Account for factors such as temperature, humidity, and potential contaminants.

- Cost and maintenance: Factor in the initial investment and ongoing maintenance costs.

4. How do you perform preventive maintenance on a gripper machine to ensure optimal performance?

- Regular visual inspections: Check for wear, damage, or leaks on jaws, cylinders, and other components.

- Pneumatic/Hydraulic system maintenance: Ensure proper air pressure, fluid levels, and filter cleanliness.

- Electrical system maintenance: Inspect wiring, connections, and sensors for damage or loose connections.

- Jaw alignment and calibration: Check and adjust jaw alignment to ensure accurate gripping.

- Software updates: Install software updates or patches to address any performance issues or bugs.

5. Describe the safety precautions to observe when operating a gripper machine?

- Proper training: Operators must receive thorough training on machine operation and safety procedures.

- PPE usage: Safety glasses, gloves, and other appropriate PPE should be worn during operation.

- Hazard identification: Be aware of potential hazards such as moving parts, pinch points, and electrical components.

- Guarding: Ensure that all moving parts are properly guarded to prevent accidental contact.

- Emergency stop: Know the location of and how to use the emergency stop button in case of an emergency.

6. How do you troubleshoot common problems that may arise with a gripper machine?

- Gripper not gripping objects: Check jaw alignment, air pressure/fluid levels, and electrical connections.

- Objects slipping from the gripper: Adjust grip force, check jaw wear or damage, or consider using a different gripper type.

- Leaking or noisy cylinders: Inspect for leaks in seals, check air pressure/fluid levels, and lubricate as necessary.

- Software errors: Restart the machine, check for software updates, and contact the manufacturer if the error persists.

- Mechanical issues: Check for loose bolts, worn gears, or other mechanical problems that may affect machine performance.

7. Describe the steps involved in programming a gripper machine to perform a specific task?

- Define the task: Clearly identify the objects to be handled, their placement, and the desired movements.

- Select the appropriate gripper: Determine the type of gripper and its specifications based on the task requirements.

- Program the motion sequence: Create a program that specifies the sequence of movements, including opening/closing jaws, moving to target positions, and any other necessary actions.

- Define inputs and outputs: Specify the sensors or inputs that trigger the gripper movements and the outputs that control the gripper.

- Test and optimize: Thoroughly test the program, make adjustments as needed, and optimize for speed and efficiency.

8. How do you optimize the performance of a gripper machine in terms of speed and accuracy?

- Use the right gripper: Choose a gripper designed for the specific task and object characteristics.

- Proper calibration: Ensure that the gripper is properly calibrated to minimize errors and maximize gripping precision.

- Optimize motion parameters: Adjust the speed and acceleration of the gripper movements based on the application requirements.

- Use feedback sensors: Integrate sensors to provide real-time feedback on object position and grip force, enabling adaptive control.

- Regular maintenance: Perform preventive maintenance as per the manufacturer’s recommendations to ensure optimal performance.

9. Discuss the advantages of using a gripper machine in a manufacturing environment?

- Increased productivity: Automation with gripper machines reduces cycle time and frees up human operators for other tasks.

- Improved accuracy and precision: Gripper machines provide consistent and precise gripping and placement of objects.

- Reduced labor costs: Automated gripping eliminates the need for manual handling, reducing labor costs.

- Enhanced safety: Gripper machines can perform tasks in hazardous environments or with heavy objects, improving worker safety.

- Improved product quality: Accurate gripping and placement reduce the risk of damage or defects.

10. What are the latest advancements or trends in gripper machine technology?

- Collaborative robots: Gripper machines integrated with collaborative robots enhance human-machine interaction.

- Adaptive gripping: Grippers with sensors and AI algorithms adapt to variations in object shape and size.

- Vision-guided gripping: Grippers with integrated vision systems enhance object recognition and precise placement.

- Wireless connectivity: Gripper machines with wireless connectivity enable remote monitoring and control.

- End-of-arm tooling: Advanced end-of-arm tooling options expand the capabilities of gripper machines for specific applications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gripper Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gripper Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Gripper Machine Operator plays a pivotal role in manufacturing processes, ensuring efficient operation of gripper machines. The primary responsibilities include:

1. Machine Operation

Effectively operate gripper machines to pick, place, and transfer materials or products.

- Calibrate and adjust machines to maintain optimum performance.

- Monitor machine functions and troubleshoot any operational issues.

2. Production Monitoring

Monitor production processes to ensure accuracy and efficiency.

- Inspect products for defects or discrepancies.

- Maintain production records and report any deviations from standard.

3. Machine Maintenance

Perform routine maintenance and cleaning of machines.

- Lubricate and repair machines as needed.

- Follow established maintenance schedules to prevent breakdowns.

4. Safety Compliance

Adhere to all safety regulations and protocols.

- Wear appropriate safety gear.

- Operate machines in a safe and responsible manner.

Interview Tips

Preparing for a Gripper Machine Operator interview requires a thorough understanding of the job responsibilities and industry knowledge. Here are some tips to help ace the interview:

1. Research the Company and Role

Familiarize yourself with the company’s products, services, and culture. Research the specific role and responsibilities to demonstrate your interest and understanding.

- Visit the company website and LinkedIn page.

- Read industry publications and articles to gain insights.

2. Highlight Relevant Experience

Emphasize your practical experience in operating gripper machines or similar equipment. Quantify your accomplishments using specific metrics.

- Describe your responsibilities in detail.

- Provide examples of how you improved efficiency or reduced machine downtime.

3. Demonstrate Technical Skills

Showcase your technical knowledge of gripper machines, including their mechanical components, programming, and troubleshooting procedures.

- Explain the principles of gripper operation.

- Discuss common maintenance procedures.

4. Emphasize Safety Awareness

Stress your commitment to safety and your understanding of industry regulations. Describe your experience in following safety protocols.

- Explain your understanding of PPE and safety procedures.

- Provide examples of how you ensure a safe work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Gripper Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.