Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hat Blocking Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

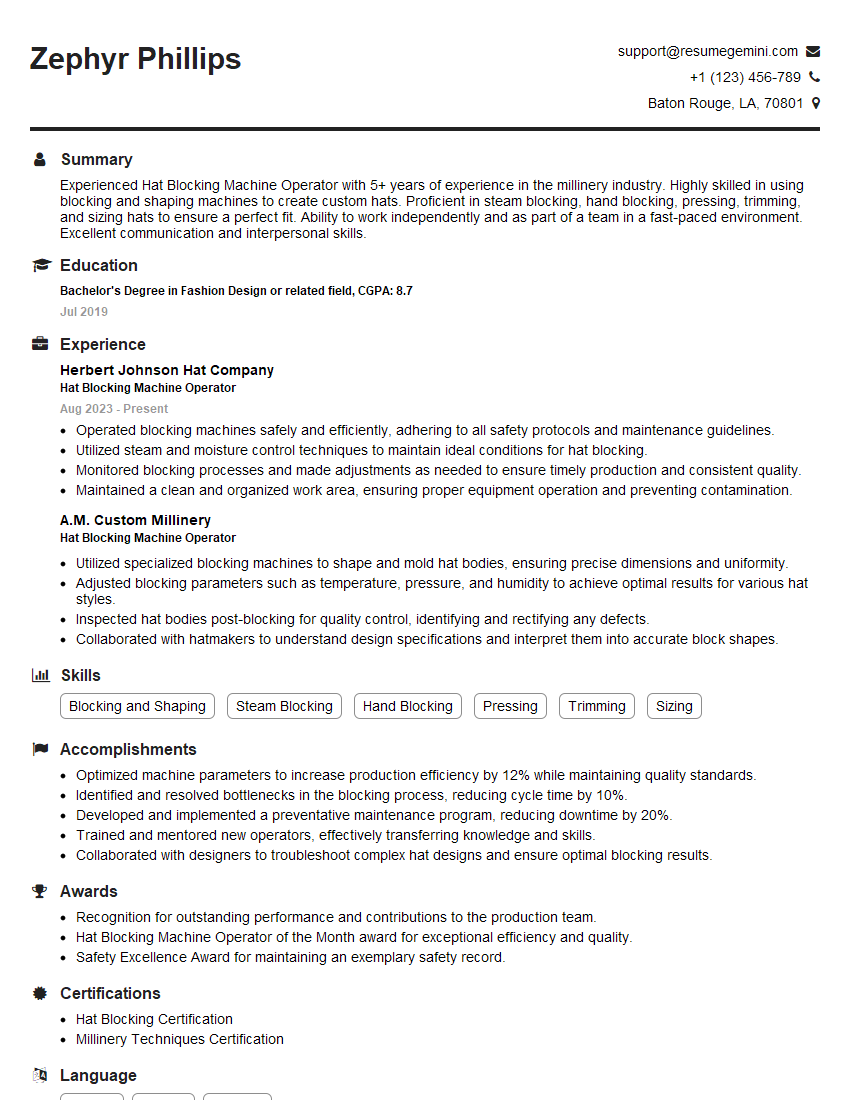

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hat Blocking Machine Operator

1. What is the purpose of a hat blocking machine?

A hat blocking machine is used to shape and form hat bodies into the desired shape and size. It uses a combination of heat, pressure, and moisture to manipulate the material and create the desired shape and style.

2. What different types of hat blocking machines are there?

Mechanical Hat Blocking Machine

- Manually operated

- Uses a mold and pressure to shape the hat

Hydraulic Hat Blocking Machine

- Uses hydraulic pressure to shape the hat

- Capable of producing complex shapes

Steam Hat Blocking Machine

- Uses steam to soften and shape the hat

- Suitable for delicate materials

3. What are the key factors to consider when selecting a hat blocking machine?

The key factors to consider when selecting a hat blocking machine include:

- Type of material to be blocked

- Desired shape and size of the finished hat

- Production volume and efficiency

- Available budget

4. What are the steps involved in operating a hat blocking machine?

The general steps involved in operating a hat blocking machine include:

- Preparing the hat body

- Loading the hat body onto the machine

- Selecting the desired shape and size

- Applying heat, moisture, and pressure

- Removing the finished hat from the machine

5. How do you maintain a hat blocking machine?

To maintain a hat blocking machine, it is recommended to:

- Clean the machine regularly

- Lubricate moving parts

- Check for wear and tear

- Calibrate the machine as necessary

6. What safety precautions should be taken when operating a hat blocking machine?

When operating a hat blocking machine, it is essential to follow safety precautions, such as:

- Wearing protective clothing and equipment

- Keeping hands away from moving parts

- Not overloading the machine

- Following all manufacturer’s instructions

7. What types of materials can be blocked on a hat blocking machine?

Various materials can be blocked on a hat blocking machine, including:

- Felt

- Straw

- Leather

- Fabric

8. How do you determine the correct temperature and pressure settings for different materials?

Determining the correct temperature and pressure settings for different materials requires knowledge and experience. It involves:

- Understanding the material’s properties

- Consulting manufacturer’s guidelines

- Experimenting with different settings to achieve the desired results

9. What are some common problems that can occur when blocking hats and how do you troubleshoot them?

Common problems during hat blocking and their troubleshooting include:

- Hat body not shaping correctly: Adjust temperature, pressure, or moisture levels.

- Hat body cracking: Use a material more suitable for blocking or reduce pressure.

- Machine malfunction: Check for loose connections, wear and tear, or follow manufacturer’s troubleshooting guide.

10. How do you stay updated on the latest techniques and technologies in hat blocking?

To stay updated in hat blocking, it is recommended to:

- Attend industry events and workshops

- Read industry publications and articles

- Connect with other hat blocking professionals

- Experiment with new techniques and materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hat Blocking Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hat Blocking Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hat Blocking Machine Operators use specialized machinery to shape and form hats from various materials such as straw, felt, and leather. Their primary duties include:

1. Machine Operation

Operate and maintain hat blocking machines, ensuring smooth functioning and optimal output.

- Adjust machine settings and calibrate equipment for different hat designs and sizes.

- Monitor machine cycles and intervene promptly to address any issues or malfunctions.

2. Hat Shaping and Forming

Place and secure hat bodies onto the blocking machine, aligning them precisely for proper shaping.

- Apply steam, heat, or pressure to mold and shape the hats according to specified dimensions.

- Inspect hats for accuracy and make necessary adjustments to achieve the desired shape and fit.

3. Quality Control

Inspect finished hats for defects and ensure they meet quality standards.

- Check for proper shape, size, and symmetry, adhering to established quality specifications.

- Identify and rectify any irregularities or imperfections by making adjustments to the blocking process.

4. Production and Efficiency

Maintain a consistent work pace to meet production targets and deadlines.

- Maximize machine utilization and minimize downtime to optimize productivity.

- Adhere to safety protocols and follow established procedures to ensure a safe and efficient work environment.

Interview Tips

Preparing for an interview for a Hat Blocking Machine Operator position requires thorough research and understanding of the industry and your own skills and experience. Here are some tips to help you ace the interview:

1. Research the Company and Position

Prior to the interview, invest time in researching the company and the specific position you are applying for. This will demonstrate your interest and enthusiasm for the role and allow you to tailor your answers to the company’s needs.

- Visit the company website to learn about their products, services, and company culture.

- Read industry publications and articles to stay informed about current trends and best practices.

2. Practice Your Answers

Take the time to carefully consider and prepare your answers to common interview questions. This will help you to present yourself confidently and clearly during the interview.

- Prepare examples of your experience that demonstrate your skills in machine operation, hat shaping, and quality control.

- Practice answering questions about your motivation for applying for the role and your career goals.

3. Dress Professionally and Arrive on Time

Make sure to dress professionally for your interview, as first impressions matter. Arrive on time for your interview, as punctuality demonstrates respect for the interviewer’s time.

- Choose clothing that is clean, pressed, and appropriate for a business environment.

- Arrive for your interview a few minutes early to allow for any unexpected delays.

4. Be Enthusiastic and Ask Questions

During the interview, show genuine enthusiasm for the position and the company. Be prepared to ask thoughtful questions about the role and the company, as this shows your interest and engagement.

- Maintain eye contact, smile, and speak clearly to project confidence and enthusiasm.

- Ask questions about the company’s growth plans, their commitment to quality, and their employee training programs.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Hat Blocking Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Hat Blocking Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.