Feeling lost in a sea of interview questions? Landed that dream interview for Mercerizer Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Mercerizer Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

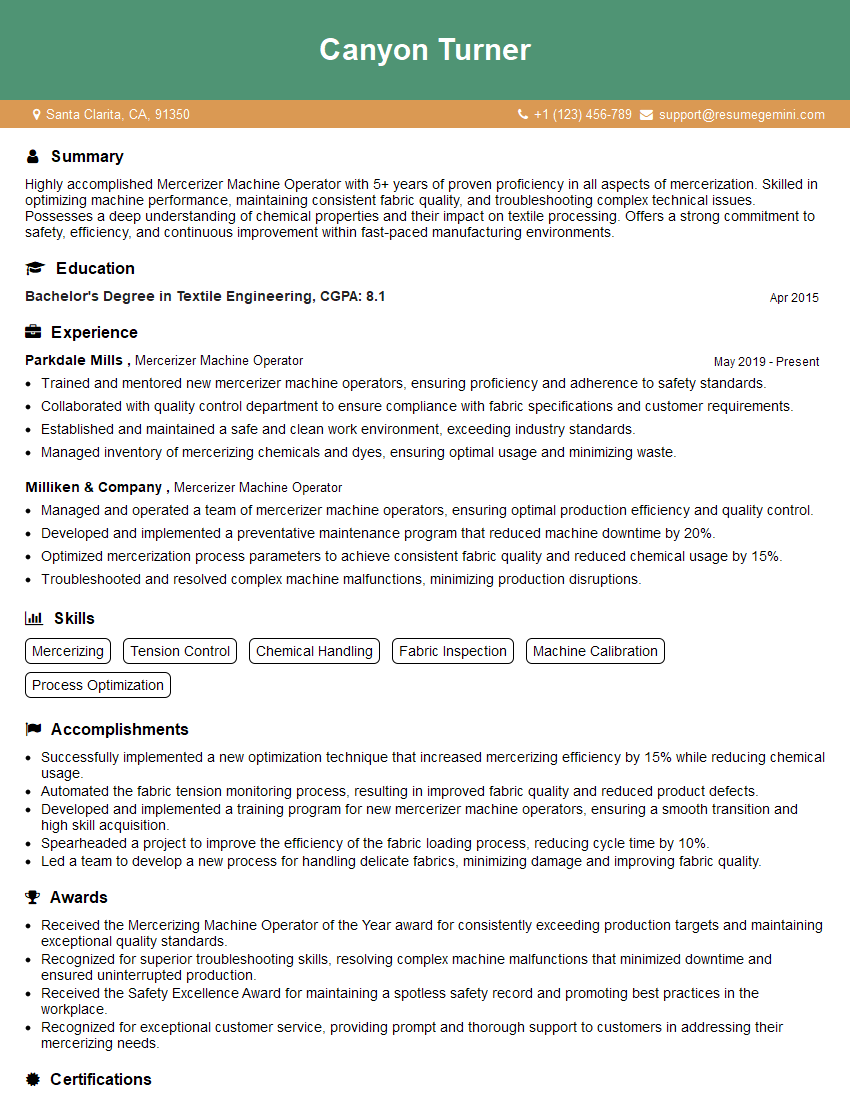

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mercerizer Machine Operator

1. What are the primary responsibilities of a Mercerizer Machine Operator?

The primary responsibilities of a Mercerizer Machine Operator include:

- Operating and maintaining mercerizing machines

- Preparing and treating fabrics for mercerization

- Monitoring and controlling the mercerization process

- Ensuring the quality of the mercerized fabrics

- Troubleshooting and resolving any issues with the machines or the process

2. What are the different types of mercerizing machines?

The most common types of mercerizing machines are:

- Batch mercerizing machines

- Continuous mercerizing machines

- Low-liquor mercerizing machines

3. What are the different stages of the mercerization process?

The mercerization process consists of the following stages:

- Pretreatment

- Steeping

- Washing

- Drying

- Curing

4. What are the key process parameters that must be controlled during mercerization?

The key process parameters that must be controlled during mercerization are:

- Temperature

- Time

- Concentration of the caustic solution

- Tension of the fabric

- Speed of the machine

5. What are the common defects that can occur during mercerization?

The common defects that can occur during mercerization are:

- Overmercerization

- Undermercerization

- Uneven mercerization

- Shrinkage

- Creasing

6. How do you troubleshoot and resolve problems that occur with mercerizing machines?

To troubleshoot and resolve problems that occur with mercerizing machines, you should follow these steps:

- Identify the problem

- Determine the cause of the problem

- Develop a solution to the problem

- Implement the solution

- Monitor the results

7. What are the safety precautions that must be taken when operating a mercerizing machine?

The safety precautions that must be taken when operating a mercerizing machine include:

- Wearing appropriate personal protective equipment (PPE)

- Following proper operating procedures

- Being aware of the hazards associated with the machine

- Knowing how to respond to an emergency

8. What are the quality control procedures that must be followed during mercerization?

The quality control procedures that must be followed during mercerization include:

- Monitoring the process parameters

- Inspecting the finished fabric

- Testing the fabric to ensure that it meets the required specifications

9. What is the difference between mercerization and sanforizing?

Mercerization and sanforizing are two different finishing processes that are used on fabrics. Mercerization is a chemical process that increases the strength, luster, and dye affinity of fabrics. Sanforizing is a mechanical process that reduces the shrinkage of fabrics.

10. What are the advantages of using mercerized fabrics?

Mercerized fabrics have several advantages, including:

- Increased strength

- Improved luster

- Greater dye affinity

- Reduced shrinkage

- Enhanced smoothness

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mercerizer Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mercerizer Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mercerizer Machine Operators are responsible for operating and maintaining mercerizing machines, which are used to treat fabrics to improve their appearance and performance. Key job responsibilities include:

Operating Mercerizing Machines

Loading and unloading fabric rolls onto the mercerizing machine

- Setting up and operating the machine according to specified parameters

- Monitoring the machine during operation to ensure proper functioning

Maintaining Mercerizing Machines

Performing routine maintenance and repairs on the mercerizing machine

- Cleaning and lubricating the machine

- Replacing worn or damaged parts

Fabric Inspection

Inspecting fabrics before and after mercerization to ensure quality

- Identifying and correcting any defects

- Taking measurements and recording data

Quality Assurance

Following established quality control procedures to ensure the production of high-quality fabrics

- Maintaining accurate records of machine settings and fabric characteristics

- Reporting any quality issues to supervisors

Interview Tips

Preparing for an interview for a Mercerizer Machine Operator position requires research, practice, and confidence. Consider the following tips to ace the interview:

Research the Company and Position

Familiarize yourself with the company’s history, products, and values. Research the specific industry and the role of a Mercerizer Machine Operator within it. This knowledge will demonstrate your interest and preparedness.

Practice Common Interview Questions

- Prepare for questions related to your experience operating and maintaining mercerizing machines.

- Practice answering questions about your quality control procedures and problem-solving abilities.

Highlight Your Skills and Experience

Emphasize your technical skills, such as machine operation, maintenance, and fabric inspection. Showcase your attention to detail and commitment to producing high-quality fabrics.

Prepare Questions to Ask the Interviewer

Asking informed questions during the interview demonstrates your engagement and interest in the opportunity. Prepare questions about the company’s growth plans, sustainability initiatives, or training opportunities.

Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately and arrive punctually for your interview. This conveys respect and professionalism.

Be Confident and Enthusiastic

Project confidence and enthusiasm throughout the interview. Highlight your passion for the textile industry and your eagerness to contribute to the team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mercerizer Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.