Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pick Pulling Machine Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

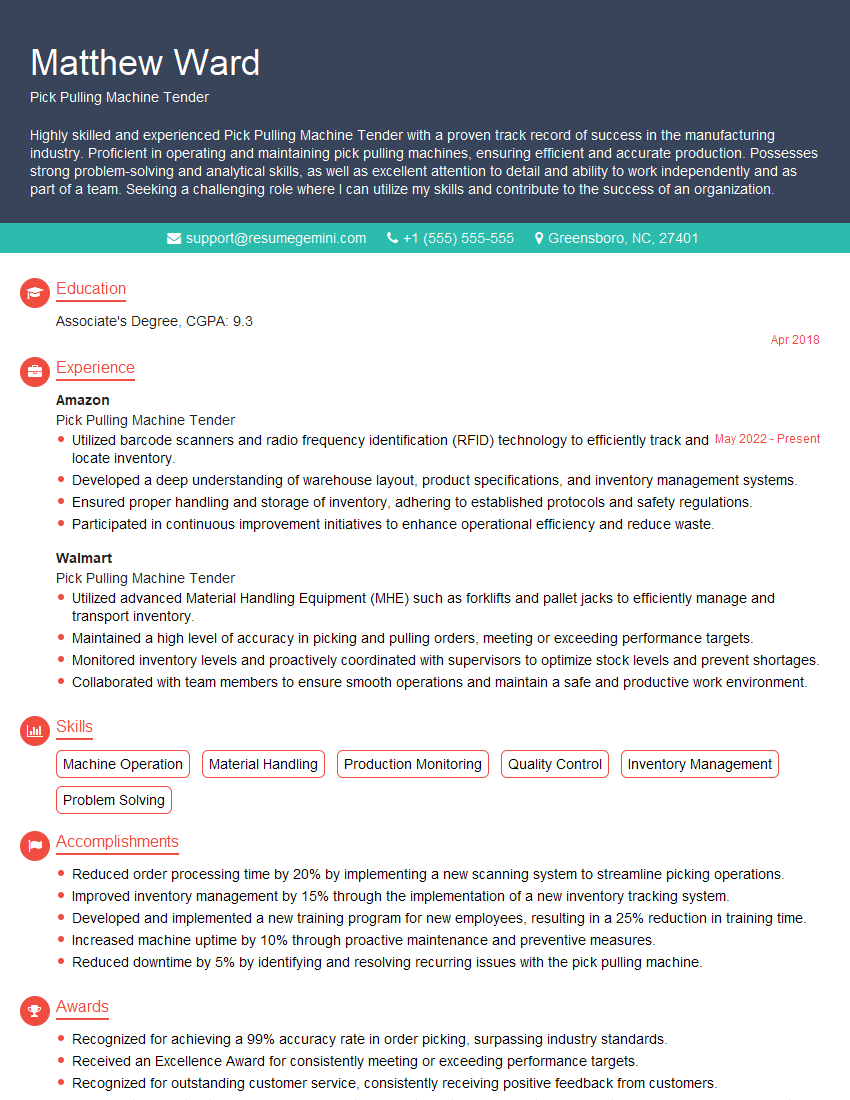

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pick Pulling Machine Tender

1. Explain the process of setting up a pick pulling machine?

- Inspect the machine for any damage or loose parts.

- Mount the correct picking head for the type of material to be picked.

- Adjust the machine settings such as speed, force, and vacuum level according to the material specifications.

- Load the material onto the machine’s conveyor belt.

- Start the machine and monitor its operation closely.

2. What are the different types of picking heads available for a pick pulling machine?

Suction cup:

- For non-porous materials such as glass, metal, and plastics.

- Comes in various shapes and sizes to accommodate different object shapes.

Mechanical gripper:

- For delicate or irregularly shaped objects.

- Uses fingers or clamps to gently grip the object.

Magnetic head:

- For ferrous materials.

- Uses a magnet to lift and move the object.

3. How do you troubleshoot a pick pulling machine that is not picking up objects properly?

- Check the vacuum level and suction cup for any damage.

- Inspect the picking head for any foreign objects or debris that may be interfering with its operation.

- Adjust the machine settings such as speed, force, and vacuum level according to the material specifications.

- Ensure that the material is properly loaded onto the conveyor belt.

- Check for any mechanical issues with the machine’s components, such as belts, gears, or motors.

4. What is the importance of performing regular maintenance on a pick pulling machine?

- Prevents breakdowns and improves machine efficiency.

- Extends the lifespan of the machine.

- Ensures optimal performance and accuracy in picking operations.

- Reduces the risk of accidents and injuries.

5. Explain the safety precautions that must be followed when operating a pick pulling machine?

- Wear appropriate personal protective equipment (PPE), such as safety glasses and gloves.

- Keep hands and other body parts away from the moving parts of the machine.

- Do not operate the machine when it is not properly set up or maintained.

- Ensure that the work area is clear of any obstacles or hazards.

- Follow all machine operating instructions and safety protocols.

6. What factors should be considered when selecting the right pick pulling machine for a specific application?

- Type of material to be picked

- Size and weight of the objects

- Required picking speed and accuracy

- Available space and budget

- Specific industry or application requirements

7. Describe the different types of sensors that can be integrated with a pick pulling machine and their uses.

- Vision sensors: Detect object presence, size, and shape

- Proximity sensors: Detect the presence of nearby objects

- Force sensors: Measure the force applied to the object during picking

- Vacuum sensors: Monitor the vacuum level for suction cup heads

- Temperature sensors: Monitor the temperature of the machine’s components

8. Explain the role of automation in pick pulling machines and its benefits.

- Increases picking speed and efficiency

- Reduces labor costs and improves productivity

- Minimizes errors and improves accuracy

- Enables integration with other automated systems

- Provides data for process optimization and quality control

9. Describe the latest advancements in pick pulling machine technology.

- Vision-based object recognition

- Collaborative robots for improved safety

- Cloud connectivity for remote monitoring

- Machine learning for predictive maintenance

- Advanced vacuum technology for improved gripping

10. How do you stay up-to-date with the latest trends and technologies in the field of pick pulling machines?

- Attend industry events and conferences

- Read technical articles and journals

- Network with professionals in the field

- Participate in online forums and discussion groups

- Explore vendor websites and product demonstrations

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pick Pulling Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pick Pulling Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pick Pulling Machine Tenders are responsible for operating and maintaining pick pulling machines, which are used to sort and package products. Key job responsibilities include:

1. Machine Operation

Operate pick pulling machines according to established procedures.

- Load and unload products from the machine

- Adjust machine settings to ensure accurate sorting and packaging

- Monitor machine performance and identify potential problems

- Perform basic troubleshooting and maintenance tasks

2. Product Handling

Handle products with care to prevent damage.

- Inspect products for defects or damage

- Sort and pack products according to specifications

- Maintain a clean and organized work area

3. Quality Control

Ensure that products meet quality standards.

- Inspect products for defects or damage

- Remove defective products from the line

- Maintain a clean and organized work area

4. Safety

Follow all safety procedures and regulations.

- Wear appropriate personal protective equipment

- Operate machines in a safe manner

- Report any unsafe conditions or practices

Interview Tips

To ace an interview for a Pick Pulling Machine Tender position, it’s essential to demonstrate your technical skills, attention to detail, and commitment to safety. Here are some tips and hacks to help you prepare:

1. Research the Company and Position

Take the time to learn about the company and the specific role you’re applying for. This will help you understand the company’s culture, values, and expectations for the position.

- Visit the company’s website

- Read industry news and articles

- Network with professionals in the field

2. Practice Your Answers

Before your interview, take some time to practice answering common interview questions. This will help you feel more confident and prepared during the interview.

- Use the STAR method (Situation, Task, Action, Result) to answer behavioral questions

- Focus on highlighting your skills and experience that are relevant to the job

- Use specific examples to support your answers

3. Dress Professionally

First impressions matter, so make sure to dress professionally for your interview. This will show the interviewer that you take the job seriously and are committed to making a good impression.

- Wear a suit or business casual attire

- Make sure your clothes are clean and pressed

- Avoid wearing strong scents or jewelry

4. Be Enthusiastic and Positive

Employers want to hire people who are enthusiastic and positive about their work. Show the interviewer that you’re excited about the opportunity to work for the company and that you’re confident in your abilities.

- Smile and make eye contact with the interviewer

- Speak clearly and confidently

- Be prepared to talk about your strengths and why you’re the right person for the job

5. Follow Up

After your interview, take the time to follow up with the interviewer. This shows that you’re interested in the position and that you appreciate their time.

- Send a thank-you note within 24 hours of the interview

- Reiterate your interest in the position

- Ask about the next steps in the hiring process

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pick Pulling Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!