Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Textile Coating Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Textile Coating Machine Operator so you can tailor your answers to impress potential employers.

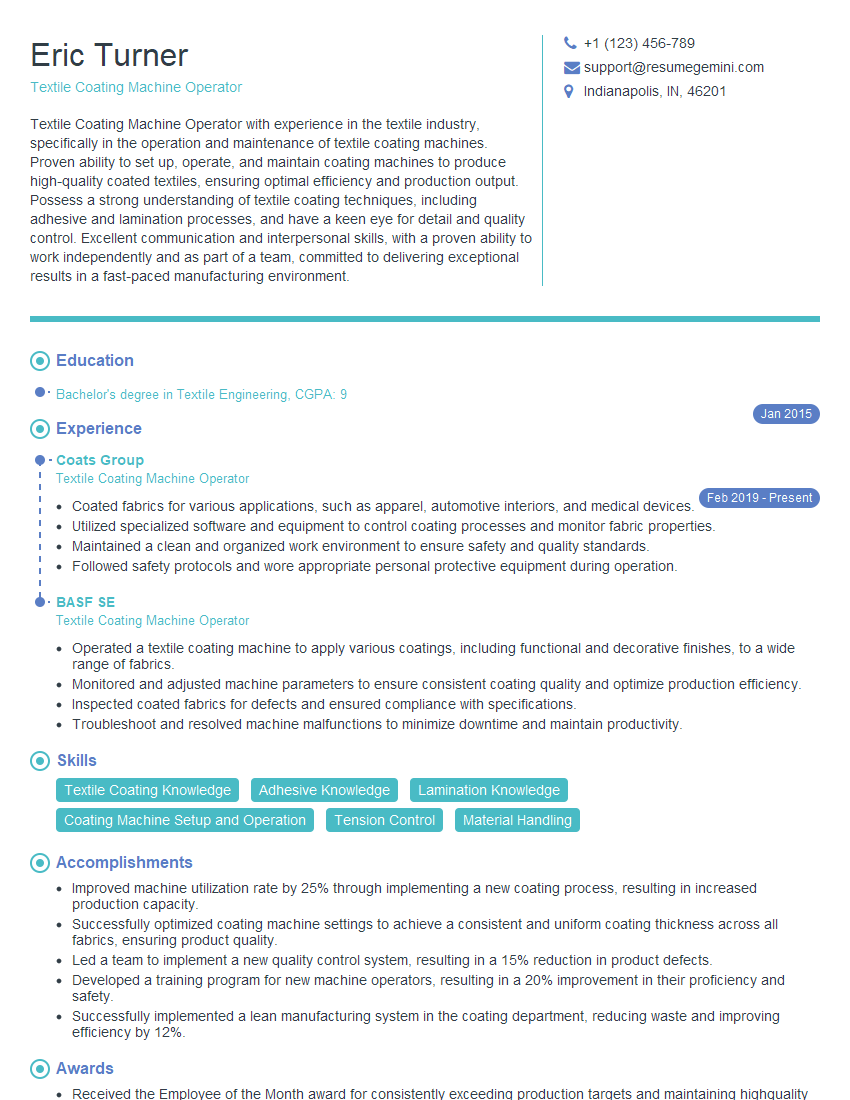

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Textile Coating Machine Operator

1. Describe the process of calibrating and adjusting coating machine for optimum coating thickness.

- Inspect the coating head, ensuring it is clean and free of debris.

- Calibrate the coating thickness gauge to ensure accurate measurements.

- Adjust the coating speed, pressure, and temperature to achieve the desired thickness.

- Monitor the coating process and make adjustments as needed to maintain consistent thickness.

- Record and document the calibration and adjustment settings for future reference.

2. How do you troubleshoot and resolve common coating defects such as uneven coating, blisters, and wrinkles?

Uneven Coating

- Check the coating head for clogs or blockages.

- Adjust the coating speed and pressure to ensure even distribution.

- Inspect the substrate for any imperfections or irregularities.

Blisters

- Reduce the coating thickness.

- Adjust the curing temperature and time to prevent trapped air or moisture.

- Use a primer or adhesive to improve adhesion between the substrate and coating.

Wrinkles

- Tighten the substrate tension.

- Increase the drying temperature to reduce moisture content.

- Use a wrinkle-resistant coating formulation.

3. Explain the importance of maintaining a clean and organized work area for textile coating operations.

- Prevents contamination of the coating materials and substrate.

- Reduces the risk of coating defects, such as uneven coating or bubbles.

- Maintains a safe and organized work environment.

- Improves efficiency and productivity by eliminating the need to search for materials or tools.

- Ensures compliance with industry regulations and quality standards.

4. Discuss the different types of coating materials used in textile coating and their properties.

- Acrylic coatings: Durable, flexible, and moisture-resistant.

- Polyurethane coatings: Strong, abrasion-resistant, and weather-resistant.

- Silicone coatings: Heat-resistant, waterproof, and anti-adhesive.

- Fluoropolymer coatings: Chemical-resistant, non-stick, and high-temperature resistant.

- Natural coatings: Derived from plants or animals, biodegradable and sustainable.

5. Describe the safety precautions that should be taken when operating textile coating machines.

- Wear appropriate personal protective equipment (PPE) including gloves, protective clothing, and safety glasses.

- Follow proper lockout/tagout procedures before servicing the machine.

- Handle coating materials with care to avoid spills or leaks.

- Maintain good ventilation to prevent the accumulation of hazardous fumes or vapors.

- Be aware of potential hazards such as moving parts, high temperatures, and electrical equipment.

6. How do you monitor and control the coating process to ensure quality and consistency?

- Regularly inspect the coated textiles for any defects or variations.

- Use quality control instruments, such as thickness gauges and spectrophotometers, to measure and assess coating properties.

- Maintain records of coating parameters, including coating thickness, temperature, and speed.

- Make adjustments to the coating process as needed to maintain consistent quality and meet customer specifications.

- Implement statistical process control techniques to monitor and improve the coating process.

7. Explain the different methods of drying coated textiles and their advantages and disadvantages.

Air Drying

- Advantages: Inexpensive, easy to implement, low energy consumption.

- Disadvantages: Slow drying time, can be affected by ambient conditions.

Convection Drying

- Advantages: Faster drying time than air drying, less affected by ambient conditions.

- Disadvantages: Requires specialized equipment, can be energy-intensive.

Radiation Drying

- Advantages: Very fast drying time, can be used for heat-sensitive materials.

- Disadvantages: High equipment cost, can cause discoloration in some materials.

8. Describe the maintenance and cleaning procedures for textile coating machines.

- Regularly clean the coating head and other components to prevent buildup and clogging.

- Inspect the machine for any wear or damage and perform necessary repairs.

- Calibrate the machine regularly to ensure accurate and consistent operation.

- Follow manufacturer’s instructions for proper maintenance and cleaning procedures.

- Maintain a maintenance log to document maintenance activities and identify areas for improvement.

9. How do you stay updated with the latest advancements and best practices in textile coating technology?

- Attend industry conferences and seminars.

- Read trade publications and technical journals.

- Consult with equipment manufacturers and coating material suppliers.

- Engage in discussions with other coating professionals.

- Participate in online forums and webinars.

10. Describe a challenging situation you faced while working as a Textile Coating Machine Operator and how you overcame it.

- Identify the specific challenge faced, such as a coating defect or malfunctioning equipment.

- Explain the steps taken to diagnose and troubleshoot the problem.

- Describe the solution implemented and the results achieved.

- Highlight any technical knowledge or problem-solving skills applied.

- Quantify the impact of the solution, such as improved coating quality or increased efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Textile Coating Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Textile Coating Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Textile Coating Machine Operators are responsible for a range of tasks throughout the production process. These include:1. Machine Setup and Maintenance

Preparing the textile coating machine by installing and configuring the necessary components for production.

- Adjusting machine settings, such as speed, temperature, and tension.

- Performing regular inspections and preventative maintenance tasks to ensure machine is in good working condition.

2. Material Handling

Loading and unloading fabrics and textiles into the coating machine.

- Inspecting the fabric for defects and making necessary adjustments.

- Monitoring the coating process to ensure that the correct materials and thickness are being used.

3. Coating Application

Controlling the flow of the coating material to ensure uniform and precise application.

- Monitoring the drying process to ensure that the coating adheres properly to the fabric.

- Making adjustments to the coating process based on the desired finish and specifications.

4. Quality Control

Inspecting coated fabrics to ensure they meet the desired quality standards.

- Performing quality control tests to check the coating’s thickness, adhesion, and appearance.

- Reporting any discrepancies or defects to the supervisor.

Interview Tips

Preparing for an interview for a Textile Coating Machine Operator position can help you increase your chances of success. Here are some tips:1. Research the Company and Position

Learn about the company’s background, products, and values.

- Research the specific Textile Coating Machine Operator role and its responsibilities.

- Identify potential interview questions and prepare your answers.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in textile coating, machine operation, and quality control.

- Provide specific examples of your experience in these areas.

- Quantify your accomplishments whenever possible, using numbers and metrics.

3. Demonstrate Attention to Detail

Textile Coating Machine Operators must be precise and meticulous in their work.

- Highlight your strong attention to detail and ability to follow instructions carefully.

- Provide examples of situations where you ensured accuracy and quality in your work.

4. Show Willingness to Learn

The textile coating industry is constantly evolving.

- Emphasize your willingness to learn new techniques and technologies.

- Express your interest in staying up-to-date on industry best practices.

5. Prepare Questions for the Interviewer

Asking well-informed questions shows your interest and engagement in the position.

- Prepare questions about the company’s growth plans, sustainability initiatives, and training opportunities.

- Questions about specific aspects of the Textile Coating Machine Operator role demonstrate your genuine interest.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Textile Coating Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.