Are you gearing up for a career in Throwster? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Throwster and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

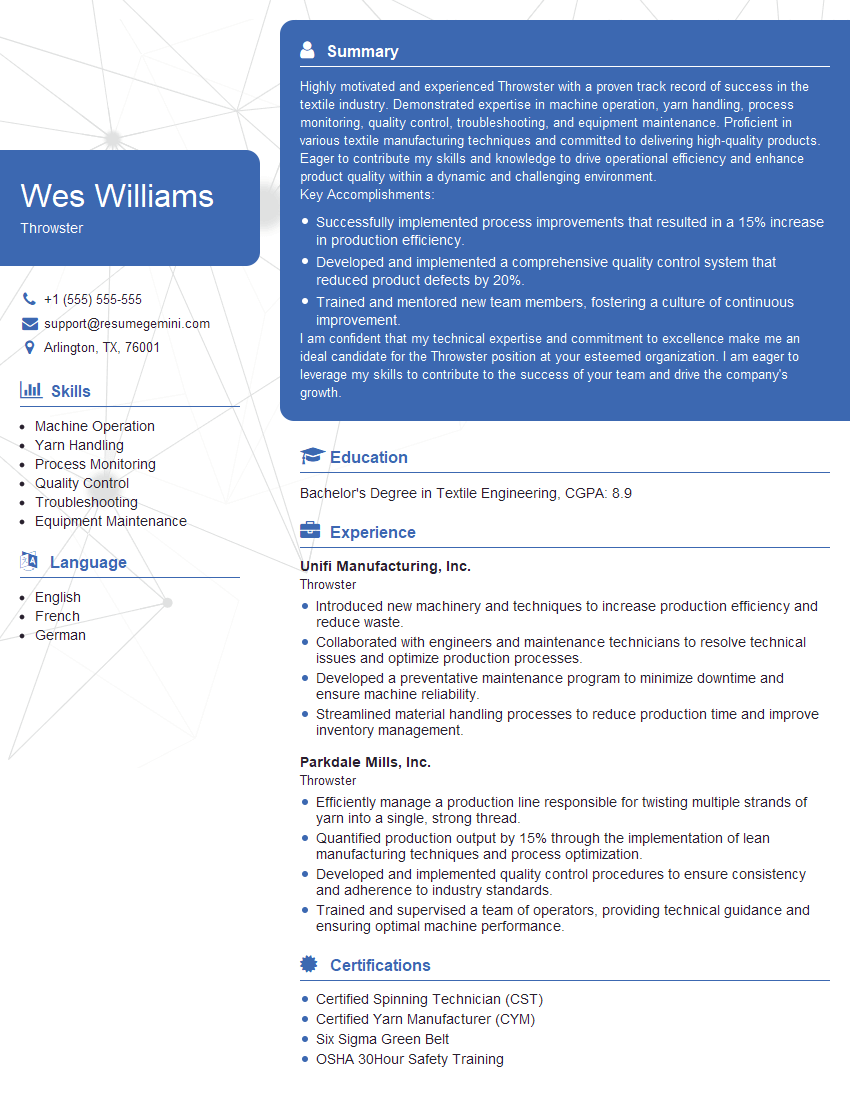

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Throwster

1. Describe the steps involved in optimizing a twisting machine for different yarn counts.

Answer: Optimizing a twisting machine for different yarn counts involves the following steps:

- Identify the desired yarn count and specifications.

- Calculate the required spindle speed and twist multiplier based on the yarn count and twist level.

- Adjust the machine parameters, such as spindle speed, tension, and winding angle, to achieve the desired twist and yarn quality.

- Monitor the machine performance and make necessary adjustments to maintain the desired yarn count and quality.

- Document the optimized machine settings for future reference.

2. Explain the principles behind different yarn twisting methods, such as ring twisting and air-jet twisting.

Answer:

Ring Twisting

- Uses a ring and traveler to impart twist to the yarn.

- Produces yarns with high twist levels and good strength.

- Suitable for a wide range of yarn counts and materials.

Air-Jet Twisting

- Uses a high-velocity air jet to impart twist to the yarn.

- Produces yarns with lower twist levels and improved softness.

- Suitable for delicate yarns and materials that are sensitive to high twist.

3. Describe the factors that affect the quality of twisted yarn.

Answer: The quality of twisted yarn is affected by several factors:

- Yarn count and twist level

- Fiber type and properties

- Machine settings (spindle speed, tension, etc.)

- Environmental conditions (temperature, humidity)

- Operator skill and experience

4. Explain the role of twist in yarn properties, such as strength, elongation, and handle.

Answer:

- Strength: Twist increases yarn strength by interlocking fibers and reducing yarn hairiness.

- Elongation: Twist reduces yarn elongation, making it less stretchy.

- Handle: Twist can affect the yarn’s handle, making it softer or harsher depending on the twist level.

5. Describe the troubleshooting techniques for common twisting machine problems, such as yarn breakage and uneven twist.

Answer: Common twisting machine problems and troubleshooting techniques:

- Yarn Breakage: Check tension settings, spindle speed, and yarn quality.

- Uneven Twist: Check spindle alignment, machine settings, and yarn tension.

- Poor Yarn Quality: Check fiber properties, machine settings, and environmental conditions.

6. Explain the maintenance procedures and safety precautions for twisting machines.

Answer:

Maintenance Procedures

- Regular cleaning and lubrication

- Spindle and bearing inspection

- Tension system calibration

- Electrical and mechanical checks

Safety Precautions

- Wear appropriate PPE (safety glasses, gloves)

- Keep hands away from moving parts

- Follow lockout/tagout procedures

- Be aware of potential tripping hazards

7. Describe the importance of quality control in yarn twisting and the different testing methods used to ensure yarn quality.

Answer: Quality control in yarn twisting ensures:

- Consistency in yarn properties

- Meeting customer specifications

- Minimizing defects and reducing waste

- Yarn count

- Twist level

- Strength and elongation

- Hairiness

- Visual inspection

8. Explain the automation and technological advancements in yarn twisting machines.

Answer: Automation and technological advancements in yarn twisting machines:

- Computerized controls for precise machine settings

- Automatic fault detection and correction systems

- Integrated yarn quality monitoring systems

- Remote monitoring and control capabilities

- Improved energy efficiency and reduced waste

9. Describe the environmental impact of yarn twisting and the measures taken to reduce it.

Answer:

- Energy consumption: Optimizing machine settings and using energy-efficient equipment.

- Waste generation: Reducing yarn breakage and waste through proper maintenance and quality control.

- Noise pollution: Using noise-dampening materials and enclosures.

- Chemical usage: Implementing proper chemical handling and disposal practices.

10. Discuss the current trends and future developments in the yarn twisting industry.

Answer: Current trends and future developments in yarn twisting:

- Increased demand for high-performance yarns

- Adoption of sustainable and eco-friendly practices

- Continued automation and digitalization

- Focus on innovation and new yarn products

- Integration with other textile processes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Throwster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Throwster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Textile Manufacturing

Throwsters are responsible for twisting yarn to create stronger, more durable threads. This process is essential in the production of textiles, and throwsters must have a thorough understanding of the machinery and techniques involved.

Some of the key responsibilities of a throwster include:

- Operating throwing machines to twist yarn

- Monitoring the machines to ensure they are running smoothly

- Maintaining the machines and making repairs

- Inspecting yarn to ensure it meets quality standards

- Following safety procedures

- Working with other members of the production team

- Maintaining production records

Maintaining Equipment

Troubleshooting

Keeping the machinery running smoothly is crucial in a manufacturing environment. Throwsters must be able to quickly identify and fix any problems that arise, to minimize downtime and maintain productivity.

Calibration

Throwsters are responsible for calibrating the throwing machines to ensure that they are producing yarn of the correct twist and tension. This requires a high level of precision and attention to detail.

Maintenance

Throwsters must also perform regular maintenance on the throwing machines to keep them in good working order. This includes cleaning, lubricating, and replacing worn parts.

Safety

Working with heavy machinery can be dangerous, so throwsters must follow all safety procedures. This includes wearing the proper safety gear and being aware of the potential hazards of the job.

Communication and Teamwork

Communication

Throwsters need to be able to communicate effectively with other members of the production team, including supervisors, engineers, and maintenance technicians. They must be able to clearly explain any problems that arise and work together to find solutions.

Teamwork

Throwsters are part of a team that is responsible for producing high-quality yarn. They must be able to work well with others and contribute to the overall success of the team.

Interview Tips

Research the Company and the Position

Before the interview, do some research on the company and the specific position you are applying for. You want to know about the company’s strengths, weaknesses, and competitive advantages. You also want to know about the specific skills and experience the company is looking for in a throwster.

Be Prepared to Talk About Your Experience

In the interview, you will be asked about your experience as a throwster. Be prepared to talk about your skills and experience in detail. You can also talk about your knowledge of the textile industry and your understanding of the throwing process.

Be Professional and Enthusiastic

Dress professionally for the interview and arrive on time. Be enthusiastic and positive throughout the interview. The interviewer wants to see that you are interested in the position and that you are confident in your abilities.

Follow Up

After the interview, send a thank you note to the interviewer. This is a good way to reiterate your interest in the position and to thank them for their time. You can also use the thank you note to ask any questions that you may have forgotten during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Throwster interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!