Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Yarn Mercerizer Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

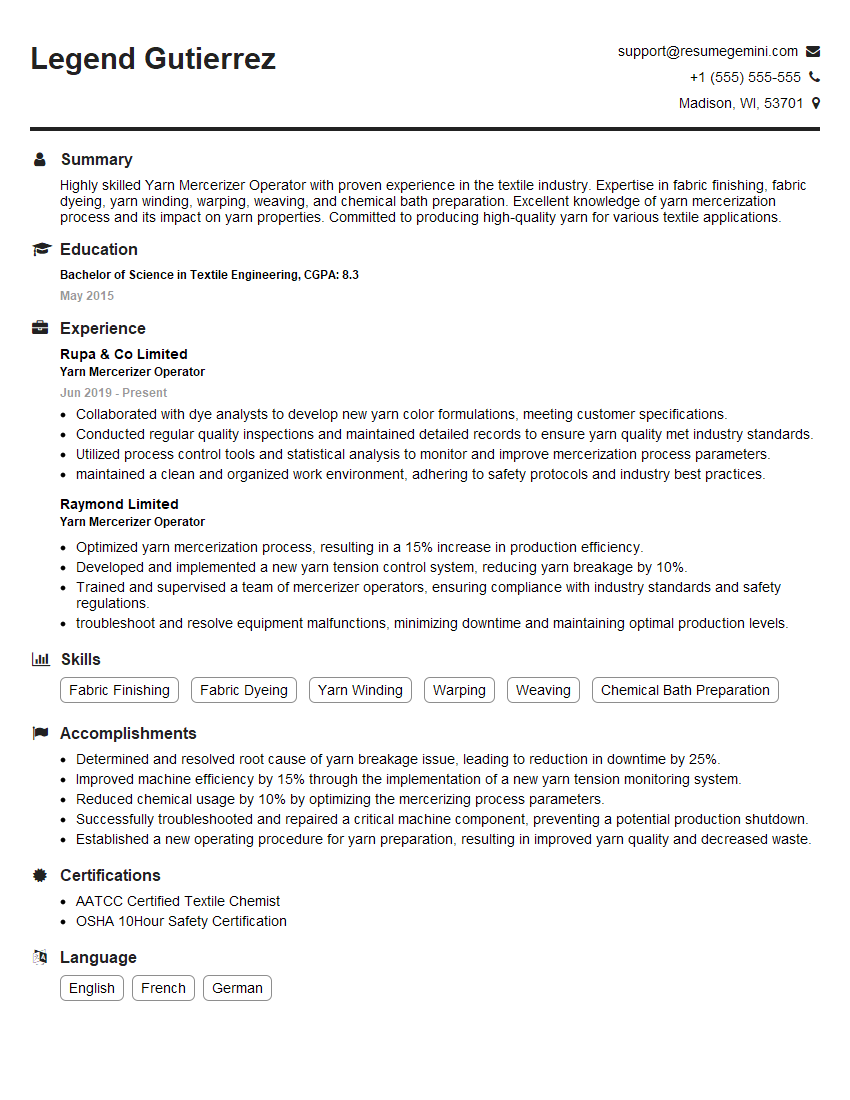

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Yarn Mercerizer Operator

1. Explain the process of yarn mercerization?

- Yarn mercerization is a chemical treatment that changes the physical and chemical properties of cotton yarn.

- The process involves treating the yarn with a strong alkali solution, such as sodium hydroxide, under tension.

- This causes the yarn to swell and the cellulose fibers to become more aligned, resulting in a stronger, smoother, and more lustrous yarn.

2. What are the key parameters that need to be controlled during the mercerization process?

Temperature

- The temperature of the alkali solution is critical to the mercerization process.

- Too high a temperature can damage the yarn, while too low a temperature will not produce the desired results.

Concentration of alkali solution

- The concentration of the alkali solution also affects the mercerization process.

- A higher concentration of alkali will produce a more pronounced mercerization effect, but it can also damage the yarn if it is too high.

Tension

- The tension applied to the yarn during mercerization is important to ensure that the yarn is stretched and the cellulose fibers are aligned.

- Too much tension can damage the yarn, while too little tension will not produce the desired results.

3. What are the benefits of yarn mercerization?

- Increased strength

- Improved luster

- Increased uniformity

- Improved dye uptake

- Reduced shrinkage

4. What are the different types of mercerizing machines?

- Batch mercerizing machines

- Continuous mercerizing machines

5. What are the safety precautions that need to be taken when working with yarn mercerization chemicals?

- Wear appropriate personal protective equipment, such as gloves, goggles, and a respirator.

- Handle chemicals with care and avoid contact with skin and eyes.

- Dispose of chemicals properly according to local regulations.

6. What are the troubleshooting tips for yarn mercerization?

- If the yarn is not mercerizing properly, check the temperature, concentration of alkali solution, and tension.

- If the yarn is damaged during mercerization, reduce the tension or concentration of alkali solution.

- If the yarn is not taking up dye evenly, check the concentration of alkali solution and the dye bath temperature.

7. What are the quality control tests that need to be performed on mercerized yarn?

- Strength test

- Luster test

- Dye uptake test

- Shrinkage test

8. What are the latest developments in yarn mercerization technology?

- Use of enzymes to improve the mercerization process

- Development of new mercerizing machines that are more efficient and environmentally friendly

- Use of nanotechnology to create new mercerized yarns with unique properties

9. What are the challenges facing the yarn mercerization industry?

- Environmental regulations

- Rising costs of raw materials

- Competition from other yarn processing technologies

10. What are the future prospects for the yarn mercerization industry?

- The yarn mercerization industry is expected to grow in the coming years due to the increasing demand for high-quality yarns.

- New developments in yarn mercerization technology are expected to make the process more efficient and environmentally friendly.

- The use of nanotechnology is expected to create new mercerized yarns with unique properties that will open up new applications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Yarn Mercerizer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Yarn Mercerizer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Yarn Mercerizer Operators are responsible for operating and maintaining yarn mercerizing machines, which use a chemical treatment to improve the strength, luster, and dye receptivity of yarn. Their key responsibilities include:

1. Machine Operation

Setting up and operating yarn mercerizing machines

- Loading yarn onto the machine

- Adjusting machine settings to achieve desired results

2. Yarn Treatment

Preparing yarn for mercerization by removing impurities and sizing

- Controlling the temperature, concentration, and duration of the mercerizing solution

- Monitoring the yarn’s progress through the machine

3. Quality Control

Inspecting yarn after mercerization to ensure it meets quality standards

- Testing yarn for strength, elasticity, and luster

- Making necessary adjustments to the mercerizing process

4. Machine Maintenance

Performing routine maintenance and repairs on mercerizing machines

- Cleaning and lubricating machine parts

- Replacing worn or damaged components

Interview Tips

To ace an interview for a Yarn Mercerizer Operator position, candidates should prepare thoroughly and demonstrate their knowledge and skills. Here are some tips:

1. Research the Company

Familiarize yourself with the company’s history, products, and values.

- Visit the company’s website

- Read industry publications and news articles

2. Practice Common Interview Questions

Prepare for questions about your experience, skills, and qualifications.

- Use the STAR method (Situation, Task, Action, Result) to answer behavioral questions

- Quantify your accomplishments whenever possible

3. Highlight Your Technical Skills

Emphasize your knowledge of yarn mercerizing processes, machinery, and quality control techniques.

- Describe your experience with specific mercerizing machines

- Explain how you ensure the quality of the yarn you produce

4. Show Your Enthusiasm

Convey your passion for the textile industry and your desire to contribute to the company’s success.

- Share your knowledge of industry trends and best practices

- Express your interest in learning and growing within the organization

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Yarn Mercerizer Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.