Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Yarn Conditioner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

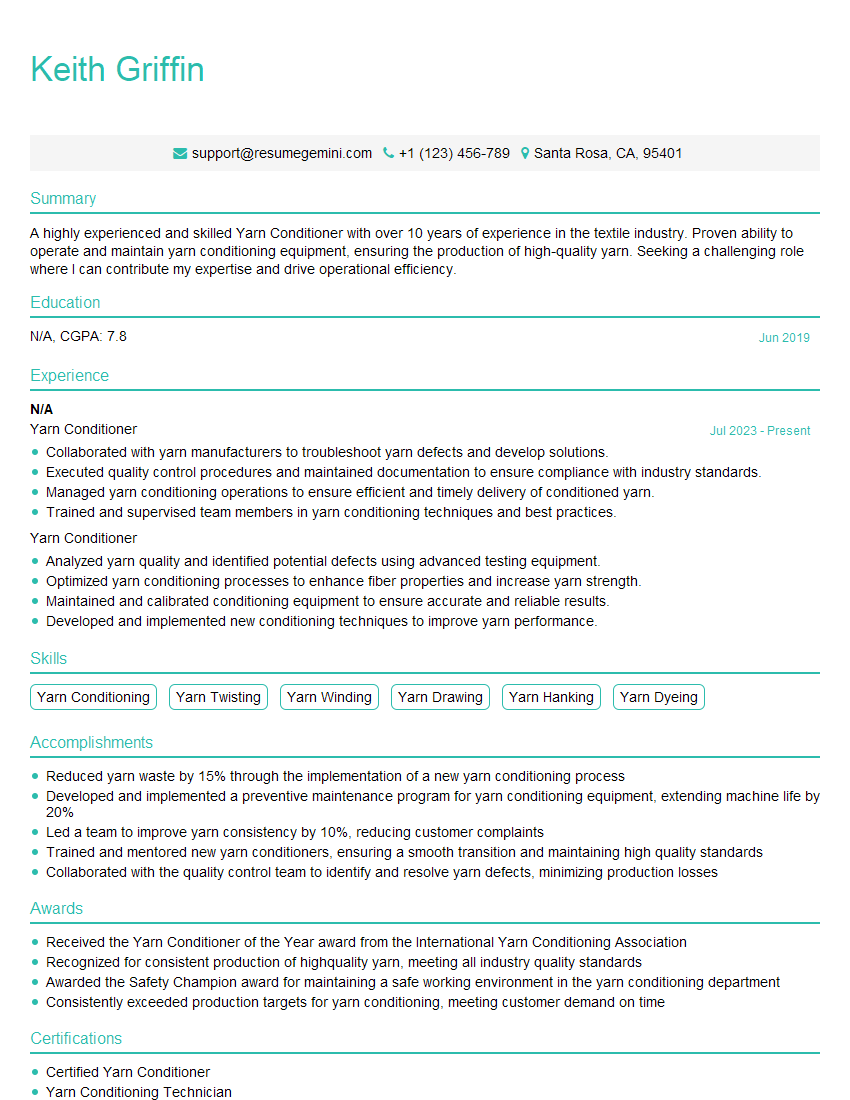

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Yarn Conditioner

1. Explain the process of yarn conditioning?

Yarn conditioning is a process of treating yarn to improve its quality and make it suitable for further processing. It involves several steps:

- Soaking: The yarn is soaked in water or a conditioning solution to remove impurities and soften the fibers.

- Extraction: The excess water or solution is extracted from the yarn using a hydroextractor.

- Drying: The yarn is dried at a controlled temperature and humidity to remove the remaining moisture.

- Cooling: The dried yarn is cooled to room temperature to prevent damage to the fibers.

2. What are the benefits of yarn conditioning?

Improved Yarn Properties:

- Increased tensile strength and elongation

- Enhanced luster and appearance

- Reduced hairiness and pilling

Process Efficiency:

- Improved dyeing and finishing results

- Reduced yarn breakage during weaving or knitting

- Increased productivity and reduced downtime

3. How do you determine the optimal conditioning parameters for different types of yarn?

Optimal conditioning parameters vary depending on the fiber composition, yarn count, and end use. Factors to consider include:

- Fiber Type: Different fibers (e.g., cotton, polyester, wool) have different moisture absorption and desorption rates.

- Yarn Count: Finer yarns require shorter conditioning times and lower temperatures to prevent damage.

- End Use: The intended use of the yarn (e.g., apparel, home textiles, industrial applications) influences the desired properties.

- Experience and Industry Standards: Industry practices and data provide guidance on suitable conditioning parameters.

4. Describe the different types of yarn conditioning machines?

Yarn conditioning machines vary in design and functionality. Common types include:

- Batch Conditioning Machines: Process small batches of yarn in a controlled environment.

- Continuous Conditioning Machines: Handle large volumes of yarn in a continuous flow process.

- Air Conditioning Machines: Use heated air to remove moisture from yarn.

- Steam Conditioning Machines: Expose yarn to steam to enhance moisture absorption.

5. Explain the role of humidity in yarn conditioning?

Humidity plays a crucial role in yarn conditioning. Controlled humidity:

- Prevents excessive moisture absorption that can weaken the fibers.

- Promotes uniform moisture distribution throughout the yarn.

- Improves the yarn’s handle and elasticity.

- Minimizes the risk of yarn breakage and defects.

6. How do you troubleshoot common problems that arise during yarn conditioning?

Common problems and troubleshooting steps include:

- Uneven Conditioning: Adjust machine settings, check temperature and humidity levels, and ensure proper yarn tension.

- Yarn Breakage: Inspect machine rollers for damage, adjust yarn tension, and check for fiber defects.

- Yarn Damage: Reduce drying temperature, shorten conditioning time, and check for chemical imbalances.

- Color Changes: Use appropriate conditioning solutions, avoid excessive heat or moisture, and consider fiber compatibility.

7. How do you ensure the quality of yarn after conditioning?

Quality assurance measures include:

- Regular testing of yarn properties (tensile strength, elongation, etc.)

- Monitoring machine settings and environmental conditions

- Visual inspection of yarn for defects and uneven conditioning

- Documentation of conditioning parameters and test results

8. Explain the effect of conditioning on yarn dyeing?

Properly conditioned yarn:

- Absorbs dye more evenly, resulting in better color fastness and shade consistency.

- Reduces dye uptake variation, leading to improved dye utilization and cost savings.

- Minimizes dye migration and bleeding, ensuring sharp color definition.

- Improves the durability and performance of dyed yarns.

9. How do you optimize energy efficiency during yarn conditioning?

Energy-saving strategies include:

- Using energy-efficient conditioning machines

- Optimizing machine settings to reduce energy consumption

- Reusing waste heat from conditioning processes

- Implementing automated controls to minimize energy losses

10. Describe the latest advancements in yarn conditioning technology?

Advancements include:

- Automated conditioning systems with real-time monitoring and control

- High-efficiency machines with reduced energy consumption

- Advanced sensors for precise humidity and temperature control

- Data analytics tools for optimizing conditioning parameters

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Yarn Conditioner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Yarn Conditioner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Yarn Conditioner is responsible for operating machines that apply conditioning agents to yarn to improve its quality and performance. This role plays a pivotal role in the textile industry, ensuring the final product meets the desired standards.

1. Machine Operation

Operate conditioning machines to apply various agents, such as waxes, oils, and softeners, to yarn.

- Monitor machine settings and adjust as needed to achieve optimal conditioning results.

- Maintain and troubleshoot conditioning machines to ensure smooth operation.

2. Yarn Quality Control

Inspect conditioned yarn to ensure it meets quality standards.

- Perform physical and chemical tests on yarn to assess its strength, elasticity, and other properties.

- Identify and resolve any issues with yarn quality to maintain product integrity.

3. Production Optimization

Optimize conditioning processes to improve yarn quality and efficiency.

- Experiment with different conditioning agents and parameters to find the optimal combination for each yarn type.

- Monitor production data and make adjustments to improve throughput and reduce waste.

4. Safety and Compliance

Adhere to safety protocols and maintain a clean and organized work environment.

- Use personal protective equipment (PPE) when handling chemicals.

- Follow environmental regulations and ensure proper disposal of conditioning agents.

Interview Tips

Preparing thoroughly for a Yarn Conditioner interview can significantly increase your chances of success. Here are some essential tips to help you ace the interview:

1. Research the Company and Role

Take the time to research the company you’re applying to and the specific role of Yarn Conditioner. Understanding their business operations, industry trends, and the responsibilities of the position will help you tailor your answers effectively.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating conditioning machines, conducting quality control tests, and optimizing production processes. Provide specific examples from your previous experience that demonstrate your technical expertise.

3. Showcase Your Process Improvement Mindset

Yarn Conditioners are often tasked with identifying and resolving issues to improve yarn quality and efficiency. Highlight your ability to analyze data, troubleshoot problems, and implement solutions that enhance the production process.

4. Emphasize Quality Assurance

Quality control is paramount for Yarn Conditioners. Explain your understanding of yarn quality standards and your commitment to maintaining the highest levels of product integrity. Describe your experience in conducting physical and chemical tests, and your ability to interpret results and take appropriate actions.

5. Communicate Effectively

Yarn Conditioners often work in a team environment and communicate with supervisors, quality control personnel, and production staff. Showcase your ability to communicate clearly and effectively, both verbally and in writing.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Yarn Conditioner, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Yarn Conditioner positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.