Are you gearing up for an interview for a Yarn Finisher position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Yarn Finisher and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

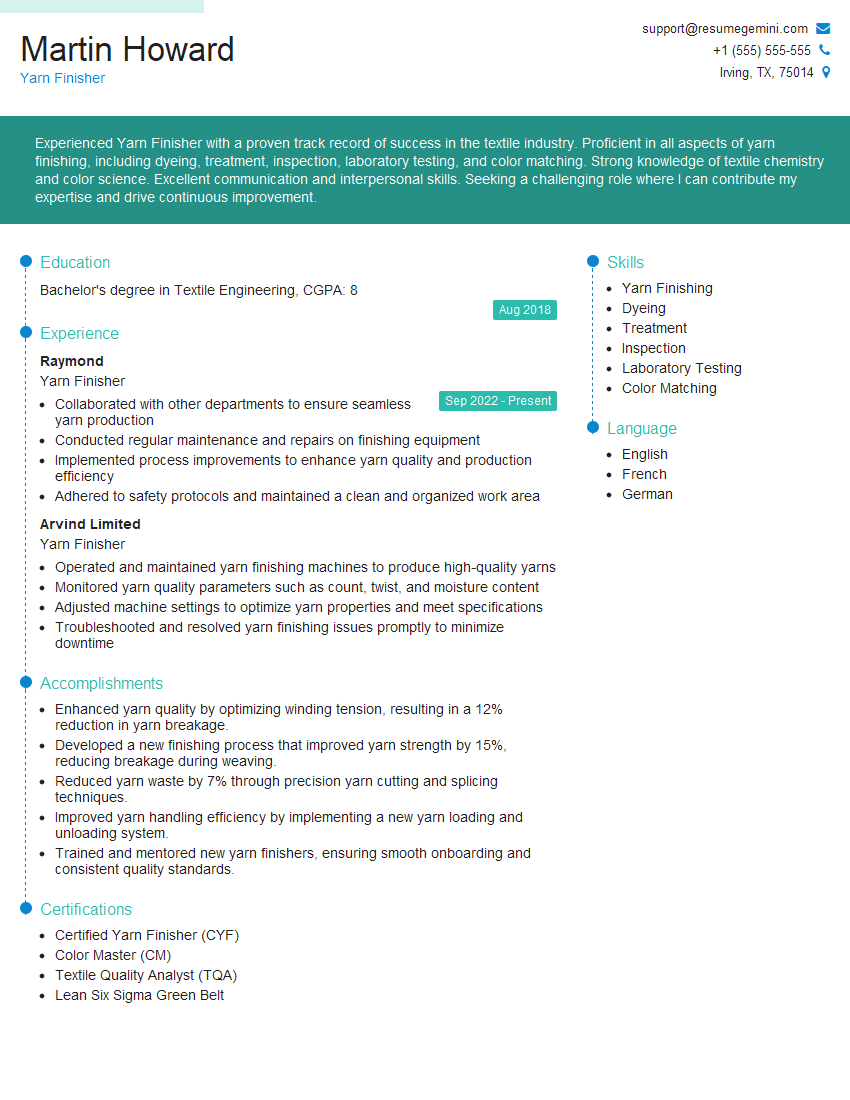

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Yarn Finisher

1. Describe the typical process flow of yarn finishing in a textile mill?

The typical process flow of yarn finishing in a textile mill includes the following steps:

- Yarn Preparation: This involves inspecting the yarn for any defects and removing any impurities or knots.

- Scouring: This process removes dirt, oil, and other contaminants from the yarn using detergents and chemicals.

- Bleaching: This process whitens the yarn using chemicals like hydrogen peroxide or sodium hypochlorite.

- Dyeing: This process adds color to the yarn using dyes and chemicals.

- Drying: This process removes excess moisture from the yarn using heat and air.

- Conditioning: This process brings the yarn to a desired moisture content and temperature to improve its handle and stability.

- Winding: This process packages the yarn onto bobbins or cones for further processing or storage.

2. What are the different methods of yarn dyeing?

Chemical Dyeing

- Direct Dyeing: Dyes attach directly to the fiber.

- Reactive Dyeing: Dyes form chemical bonds with the fiber.

Physical Dyeing

- Disperse Dyeing: Dyes disperse in water and migrate into the fiber.

- Vat Dyeing: Dyes are reduced to colorless form and then oxidized to colored form within the fiber.

Other Methods

- Space Dyeing: Creates patterns by dyeing portions of the yarn in different colors.

- Yarn Printing: Prints designs and patterns on the yarn.

3. What are the key quality parameters to consider when evaluating the finished yarn?

- Strength: The ability of the yarn to withstand breaking under tension.

- Elongation: The amount the yarn can stretch before breaking.

- Evenness: The consistency of the yarn’s diameter and thickness.

- Hairiness: The presence of loose fibers on the yarn’s surface.

- Colorfastness: The resistance of the yarn’s color to fading or bleeding.

- Moisture Content: The amount of moisture present in the yarn.

4. Describe the types of machinery used in yarn finishing?

- Scouring Machines: Used for removing impurities from yarn using water, detergents, and chemicals.

- Bleaching Machines: Used for whitening yarn using chemicals like hydrogen peroxide or sodium hypochlorite.

- Dyeing Machines: Used for adding color to yarn using dyes and chemicals.

- Drying Machines: Used for removing excess moisture from yarn using heat and air.

- Conditioning Machines: Used for bringing yarn to a desired moisture content and temperature.

- Winding Machines: Used for packaging yarn onto bobbins or cones.

5. What are the common challenges faced in yarn finishing and how do you overcome them?

- Yarn Breakage: Can be overcome by using high-quality yarn, proper tension control, and regular machine maintenance.

- Color Variation: Can be overcome by using accurate dye recipes, proper temperature control, and consistent dyeing times.

- Uneven Dyeing: Can be overcome by ensuring proper yarn preparation, using high-quality dyes, and optimizing dyeing conditions.

- Excess Moisture: Can be overcome by using efficient drying machines and maintaining proper drying conditions.

- Yarn Contamination: Can be overcome by implementing strict quality control measures throughout the finishing process.

6. How do you ensure the safety of workers in a yarn finishing environment?

- Proper Training: Train workers on safe work practices and hazardous materials handling.

- Protective Gear: Provide workers with appropriate protective gear, such as gloves, masks, and safety glasses.

- Ventilation: Ensure adequate ventilation to remove harmful fumes and dust.

- Emergency Procedures: Establish clear emergency procedures and train workers on how to respond.

- Regular Inspections: Conduct regular inspections of equipment and work areas to identify potential hazards.

7. Describe the role of quality control in yarn finishing?

- Yarn Inspection: Inspect yarn for defects, unevenness, and colorfastness.

- Process Monitoring: Monitor yarn finishing processes to ensure they meet quality standards.

- Data Analysis: Analyze quality data to identify trends and areas for improvement.

- Continuous Improvement: Implement quality improvement initiatives to enhance yarn quality and reduce defects.

8. What are the emerging technologies and trends in yarn finishing?

- Automation: Using automated systems to enhance efficiency and reduce labor costs.

- Digital Dyeing: Using digital printing technology to create complex and precise patterns on yarn.

- Sustainable Finishing: Employing eco-friendly processes and materials to reduce environmental impact.

- Performance Enhancement: Developing advanced finishing techniques to improve yarn properties, such as strength, moisture management, and antimicrobial performance.

9. How do you stay updated with the latest developments in yarn finishing technology?

- Industry Events: Attend industry exhibitions and conferences to learn about new technologies and trends.

- Training Programs: Participate in training programs offered by machinery manufacturers and industry associations.

- Technical Journals: Read industry-related journals and publications to stay informed about research and innovations.

- Networking: Connect with professionals in the yarn finishing field to exchange knowledge and ideas.

10. Why are you interested in this Yarn Finisher position at our company?

I am very enthusiastic about this Yarn Finisher position at your esteemed company because it aligns perfectly with my skills, experience, and career aspirations. With my in-depth knowledge of yarn finishing processes, quality control techniques, and industry best practices, I am confident that I can make significant contributions to your team.

Moreover, I am eager to leverage my expertise to optimize yarn finishing operations, reduce defects, and enhance the overall quality of your products. I am also keen on staying abreast of the latest technological advancements and implementing sustainable practices in my work.

I am confident that my dedication, teamwork abilities, and commitment to delivering exceptional results would make me a valuable asset to your organization. I am eager to learn from experienced professionals, contribute to the company’s success, and grow within this role.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Yarn Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Yarn Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Yarn Finisher is a textile professional responsible for the final stages of yarn production, ensuring its quality and conformance to specifications. The key job responsibilities include:

1. Yarn Inspection

Inspecting yarn for defects, impurities, and adherence to specifications.

- Using visual and mechanical inspection techniques to identify flaws.

- Checking yarn properties such as count, twist, strength, and color.

2. Yarn Conditioning

Controlling yarn moisture content and temperature to maintain optimal quality.

- Operating conditioning machines to adjust yarn properties.

- Monitoring humidity and temperature levels to ensure proper yarn conditioning.

3. Yarn Dyeing and Finishing

Dyeing and finishing yarn to enhance its aesthetic and functional properties.

- Selecting appropriate dyes and chemicals for yarn dyeing.

- Operating dyeing equipment and monitoring dye application process.

- Applying finishes such as softeners, lubricants, and flame retardants.

4. Yarn Packaging and Storage

Packaging and storing yarn to protect it from damage and ensure proper inventory management.

- Selecting packaging materials and methods to maintain yarn quality.

- Storing yarn in controlled environments to prevent moisture absorption or degradation.

- Maintaining inventory records and ensuring proper stock levels.

Interview Tips

To ace an interview for a Yarn Finisher position, candidates should prepare thoroughly and demonstrate their knowledge, skills, and experience. Here are some tips:

1. Research the Company and Role

Familiarize yourself with the company’s background, products, and reputation in the industry. Research the specific role, understanding its key responsibilities and expectations.

- Visit the company’s website and social media pages.

- Read industry publications and articles related to yarn finishing.

- Prepare questions to ask the interviewer about the company and the role.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in yarn inspection, conditioning, dyeing, and finishing. Showcase your proficiency in operating machinery and handling chemicals.

- Provide specific examples of how you have applied these skills in previous roles.

- Quantify your accomplishments, such as reducing yarn defects or improving yarn quality.

- Be prepared to discuss your knowledge of industry standards and best practices.

3. Demonstrate Attention to Detail and Quality

Yarn finishing requires meticulous attention to detail and a commitment to quality. Highlight your ability to identify defects, follow specifications, and maintain a high level of accuracy.

- Describe your experience using inspection techniques and quality control systems.

- Emphasize your commitment to meeting or exceeding customer expectations.

- Provide examples of how you have identified and resolved quality issues.

4. Showcase Teamwork and Communication Skills

Yarn Finishers often work within a team environment and need to communicate effectively with colleagues, supervisors, and customers.

- Describe your experience working in a team-based setting.

- Provide examples of how you have communicated effectively with others, both verbally and in writing.

- Emphasize your ability to listen attentively and respond appropriately.

5. Prepare for Common Interview Questions

Practice answering common interview questions related to yarn finishing, such as:

- “Tell me about your experience in yarn inspection and quality control.”

- “Describe the different yarn dyeing and finishing techniques you are familiar with.”

- “How do you ensure that yarn meets customer specifications?”

- “What are the key challenges you have faced in yarn finishing, and how did you overcome them?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Yarn Finisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!