Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wood Machinist position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

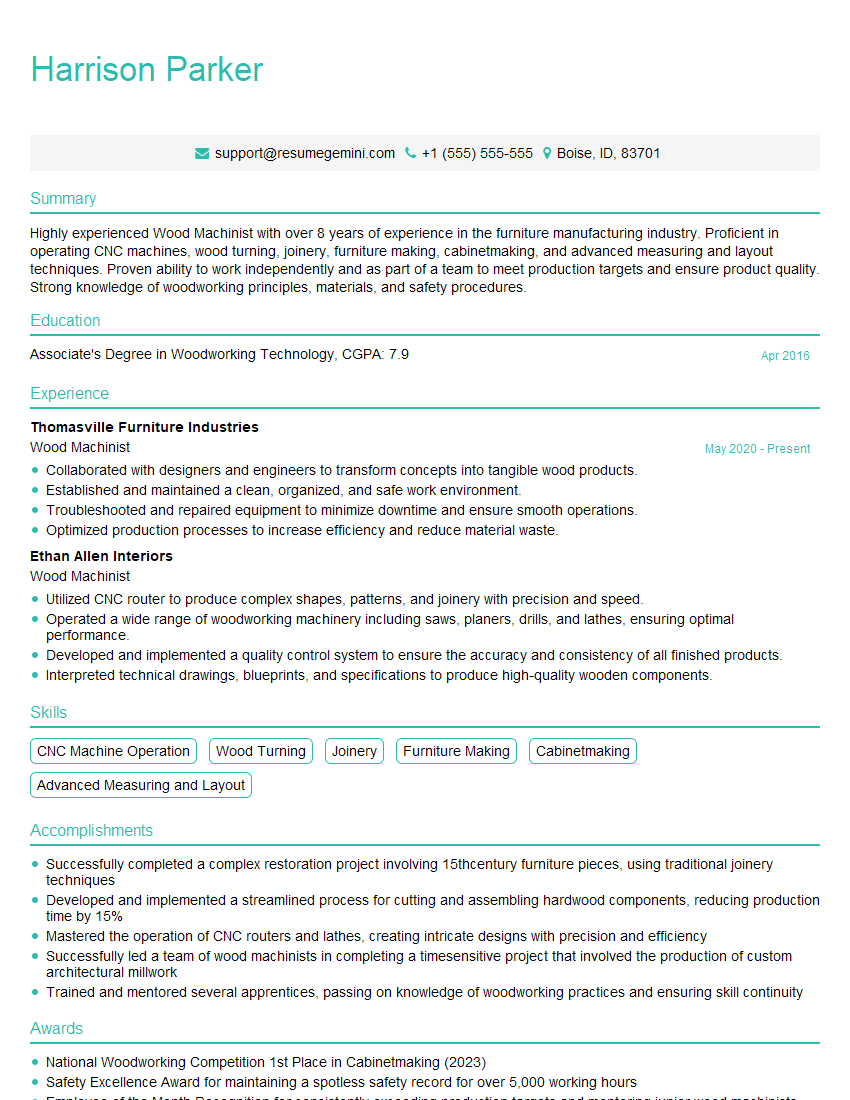

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Machinist

1. Tell me about your experience with different types of wood joinery techniques?

I have extensive experience with a wide range of wood joinery techniques, including:

- Butt joints: This is a simple and common joint used to connect two pieces of wood end-to-end.

- Edge joints: This joint is used to connect two pieces of wood along their edges, creating a stronger and more durable joint than a butt joint.

- Miter joints: This joint is used to connect two pieces of wood at a 90-degree angle, creating a clean and finished look.

- Dovetail joints: This is a strong and durable joint that is often used in furniture making and other fine woodworking applications.

- Mortise and tenon joints: This joint is used to connect two pieces of wood perpendicular to each other, creating a very strong and stable joint.

2. What are the different types of wood machining tools and their uses?

Cutting tools

- Saws: Used for cutting wood to length or shape.

- Knives: Used for shaping and smoothing wood.

- Drills: Used for creating holes in wood.

Shaping tools

- Routers: Used for shaping and profiling wood.

- Sanders: Used for smoothing and finishing wood.

- Grinders: Used for sharpening cutting tools.

3. How do you ensure accuracy and precision when working with wood?

I use a variety of tools and techniques to ensure accuracy and precision when working with wood, including:

- Measuring tools: I use precision measuring tools, such as rulers, calipers, and micrometers, to ensure that my cuts and measurements are accurate.

- Layout tools: I use layout tools, such as squares, protractors, and compasses, to mark out the cuts and shapes that I need to make.

- Jigs and fixtures: I use jigs and fixtures to hold the wood in place and guide my cuts and measurements.

- Careful setup: I take the time to carefully set up my tools and workpiece before making any cuts.

4. What are the safety precautions that you take when operating wood machinery?

I take a number of safety precautions when operating wood machinery, including:

- Wearing proper safety gear: I always wear safety glasses, gloves, and ear protection when operating wood machinery.

- Keeping the work area clean and organized: I keep my work area clean and organized to avoid tripping or falling hazards.

- Inspecting tools before use: I always inspect my tools before use to make sure that they are in good working order.

- Following proper operating procedures: I always follow the proper operating procedures for each machine that I use.

5. How do you maintain and troubleshoot wood machinery?

I perform regular maintenance on my wood machinery to keep it in good working order and prevent problems. This includes:

- Cleaning and lubricating: I clean and lubricate my machines regularly to prevent rust and wear.

- Sharpening cutting tools: I sharpen my cutting tools regularly to ensure that they are sharp and efficient.

- Troubleshooting: If I experience any problems with my machines, I troubleshoot the problem and make the necessary repairs or adjustments.

6. What are the different types of wood finishes and their uses?

There are a variety of different wood finishes available, each with its own unique properties and uses. Some of the most common types of wood finishes include:

- Oil finishes: Oil finishes penetrate into the wood and provide a natural-looking finish that enhances the wood’s grain.

- Varnish finishes: Varnish finishes create a protective coating over the wood that is resistant to moisture and scratches.

- Lacquer finishes: Lacquer finishes are similar to varnish finishes, but they are more durable and resistant to chemicals.

- Shellac finishes: Shellac finishes are made from a natural resin and provide a hard and durable finish that is resistant to alcohol and water.

7. How do you choose the right wood finish for a particular project?

When choosing a wood finish for a particular project, I consider a number of factors, including:

- The type of wood: Different types of wood have different properties, so it is important to choose a finish that is compatible with the type of wood that you are using.

- The desired look: The desired look of the finished product is also an important factor to consider when choosing a wood finish.

- The intended use: The intended use of the finished product will also influence the choice of wood finish.

8. What are the different types of woodworking machines and their uses?

There are a variety of different woodworking machines available, each with its own unique purpose. Some of the most common types of woodworking machines include:

- Table saws: Table saws are used to cut wood to length or shape.

- Miter saws: Miter saws are used to cut angles in wood.

- Drill presses: Drill presses are used to drill holes in wood.

- Sanders: Sanders are used to smooth and finish wood.

- Routers: Routers are used to shape and profile wood.

9. What are the different types of wood joints and their uses?

There are a variety of different wood joints available, each with its own unique purpose. Some of the most common types of wood joints include:

- Butt joints: Butt joints are the simplest type of wood joint, and they are used to connect two pieces of wood end-to-end.

- Edge joints: Edge joints are used to connect two pieces of wood along their edges.

- Miter joints: Miter joints are used to connect two pieces of wood at a 90-degree angle.

- Dovetail joints: Dovetail joints are strong and durable joints that are often used in furniture making.

- Mortise and tenon joints: Mortise and tenon joints are strong and durable joints that are often used in construction.

10. What are the different types of wood materials and their properties?

There are a variety of different wood materials available, each with its own unique properties. Some of the most common types of wood materials include:

- Hardwoods: Hardwoods are strong and durable woods that are often used in furniture making and other applications where strength is important.

- Softwoods: Softwoods are less strong and durable than hardwoods, but they are more affordable and easier to work with.

- Plywood: Plywood is a composite wood material that is made from thin layers of wood that are glued together.

- MDF: MDF is a composite wood material that is made from wood fibers that are bonded together with resin.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wood Machinists play a crucial role within the manufacturing industry, operating and maintaining various woodworking machinery to create high-quality wood products. Their key responsibilities include:1. Machine Operation

Wood Machinists operate a wide range of woodworking machinery, including saws, planers, molders, and sanders. They must be proficient in setting up and calibrating these machines to achieve precise and efficient cutting, shaping, and finishing of wood components.

2. Material Handling

Wood Machinists are responsible for handling and moving raw materials and finished products throughout the production process. This involves loading and unloading materials onto machinery, ensuring proper feeding and removal during processing, and safely storing and transporting finished goods.

3. Quality Control

Wood Machinists are expected to maintain high standards of quality control throughout the production process. They regularly inspect raw materials and finished products to ensure they meet specifications, identifying and addressing any defects or deviations from the desired outcome.

4. Machine Maintenance

Wood Machinists are often responsible for basic maintenance and upkeep of their machinery. They perform regular cleaning, lubrication, and minor repairs to ensure optimal performance, prevent breakdowns, and extend the lifespan of their equipment.

5. Safety Compliance

Wood Machinists must adhere strictly to safety protocols and regulations in the workplace. They wear appropriate personal protective equipment (PPE), follow established safety procedures, and ensure that their work environment is free from hazards, minimizing the risk of accidents or injuries.

Interview Tips

To ace an interview for a Wood Machinist position, candidates should consider the following tips:1. Research the Company and Industry

Before the interview, thoroughly research the company and the industry they operate in. This will give you a good understanding of their business, values, and current trends, allowing you to tailor your answers accordingly.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful and concise answers. Practice delivering your responses clearly and professionally, highlighting your skills, experience, and enthusiasm for the role.

3. Showcase Your Skills and Experience

Emphasize your proficiency in operating and maintaining woodworking machinery, and provide specific examples of your accomplishments and contributions in previous roles. Quantify your achievements whenever possible using specific metrics.

4. Ask Relevant Questions

Prepare a list of thoughtful questions to ask the interviewer at the end of the interview. This demonstrates your interest in the position, the company, and the industry, and gives you an opportunity to clarify any remaining doubts.

5. Be Professional and Enthusiastic

Dress professionally, arrive on time for the interview, and maintain a positive and enthusiastic attitude throughout. Show that you are eager to join the team and contribute to the company’s success.

With these tips and a thorough understanding of the key job responsibilities, candidates can significantly improve their chances of impressing the interviewer and securing the Wood Machinist position.Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wood Machinist interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.