Feeling lost in a sea of interview questions? Landed that dream interview for Bolt Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Bolt Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

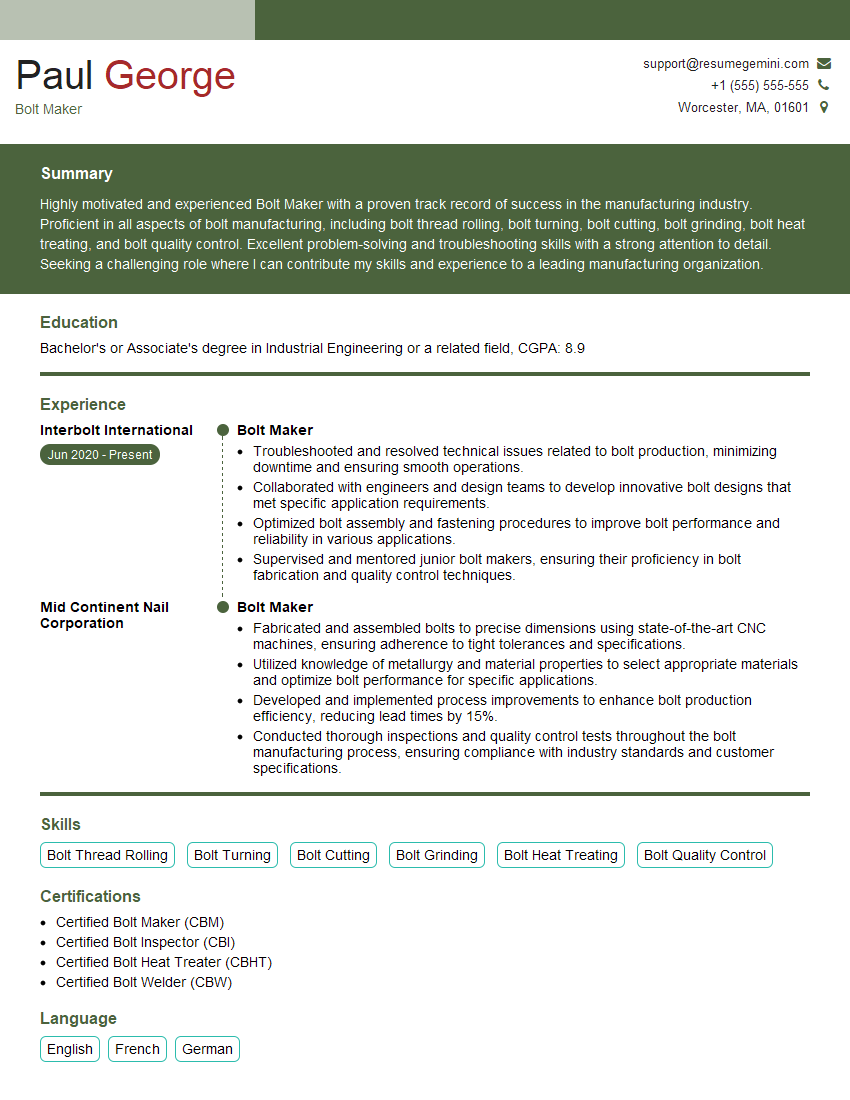

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bolt Maker

1. What are the different types of bolts you have made in the past?

In previous roles, I have experience in manufacturing a wide range of bolts, including:

- Hex bolts

- Socket bolts

- Cap screws

- Set screws

2. What is the process of making a bolt?

Heading

- The raw material, typically steel, is cut to the desired length.

- The head of the bolt is formed by hammering or pressing the metal.

Threading

- The threads are cut into the bolt using a thread rolling or cutting machine.

- The pitch and diameter of the threads are carefully controlled to ensure they meet specifications.

Heat Treatment

- The bolts may undergo heat treatment to improve their strength and durability.

- This process involves heating the bolts to a specific temperature and then cooling them in a controlled manner.

Coating

- The bolts may be coated with a protective layer, such as zinc or nickel plating, to resist corrosion.

- This coating extends the lifespan of the bolts, especially in harsh environments.

3. What are the different types of materials used to make bolts?

Bolts can be made from various materials, each with its unique properties:

- Steel: Commonly used for its strength and durability, available in different grades and alloys.

- Stainless Steel: Resistant to corrosion and oxidation, suitable for marine or chemical environments.

- Brass: Offers corrosion resistance and good machinability, often used in electrical applications.

- Aluminum: Lightweight and corrosion-resistant, but has lower strength compared to steel.

- Titanium: High strength, lightweight, and excellent corrosion resistance, used in aerospace and high-performance applications.

4. What are the factors to consider when selecting the right type of bolt for an application?

Choosing the appropriate bolt for an application requires considering several factors:

- Tensile Strength: The bolt’s ability to withstand pulling forces without breaking.

- Shear Strength: The bolt’s resistance to forces that cause it to slide or break parallel to the threads.

- Material Compatibility: Ensuring the bolt material is suitable for the environment and application.

- Corrosion Resistance: Selecting a bolt material that can withstand the corrosive elements in the environment.

- Dimensions: Matching the bolt’s length, diameter, and thread pitch to the specific requirements.

5. What are the common quality control checks performed during bolt production?

Quality control measures are crucial to ensure the bolts meet specifications:

- Dimensional Inspection: Verifying the bolt’s dimensions, including length, diameter, and thread pitch.

- Tensile Testing: Evaluating the bolt’s tensile strength by pulling it until it breaks.

- Shear Testing: Assessing the bolt’s shear strength by applying force parallel to the threads.

- Visual Inspection: Checking for defects such as cracks, burrs, or uneven threads.

- Coating Inspection: Ensuring the protective coating meets the required thickness and adherence standards.

6. How do you stay updated on the latest industry standards and best practices for bolt manufacturing?

Staying abreast of advancements in the field is essential:

- Attending Industry Conferences: Participating in conferences and workshops to learn about new technologies and industry trends.

- Reading Trade Publications: Subscribing to industry magazines and journals to stay informed about the latest research and best practices.

- Participating in Online Forums: Joining online communities and discussion groups to connect with other professionals and exchange ideas.

- Training and Certifications: Completing training programs and obtaining certifications to demonstrate proficiency in up-to-date manufacturing techniques.

7. What are the safety precautions that need to be taken when working with bolt-making machinery?

Safety is paramount in a bolt manufacturing environment:

- Wearing Proper Protective Gear: Using safety glasses, gloves, and earplugs to protect against hazards.

- Operating Machinery Carefully: Following established procedures and avoiding loose clothing or jewelry that can get caught.

- Maintaining a Clean Work Area: Keeping the work area organized and free of tripping hazards.

- Inspecting Equipment Regularly: Checking machinery for any damage or malfunctions before use.

- Adhering to Emergency Protocols: Knowing the emergency shutdown procedures and evacuation routes.

8. How do you handle production deadlines and ensure timely delivery of bolt orders?

Timely delivery is crucial in meeting customer expectations:

- Planning and Scheduling: Creating a production schedule that allocates resources effectively and allows for buffer time.

- Monitoring Progress: Regularly tracking production progress and identifying any potential delays or bottlenecks.

- Communicating with Customers: Keeping customers informed about the status of their orders and providing updates if there are any changes.

- Prioritizing Urgent Orders: Adjusting the production schedule to accommodate urgent orders while considering overall delivery commitments.

- Continuous Improvement: Regularly reviewing and improving production processes to increase efficiency and reduce lead times.

9. What is your approach to troubleshooting and resolving production issues that may arise during bolt manufacturing?

Problem-solving is essential for maintaining smooth production:

- Identifying the Root Cause: Analyzing the issue to determine its underlying cause rather than just treating symptoms.

- Considering Multiple Solutions: Exploring various options to resolve the issue, evaluating their potential impact and feasibility.

- Implementing and Monitoring Solutions: Implementing the chosen solution and closely monitoring its effectiveness.

- Documenting the Process: Recording the issue, its cause, and the implemented solution for future reference.

- Preventive Measures: Identifying steps to prevent similar issues from recurring in the future.

10. How do you ensure the quality of the bolts produced and maintain consistency in manufacturing standards?

Quality assurance is vital to maintaining customer satisfaction:

- Adhering to Quality Standards: Complying with established quality standards and industry specifications.

- Regular Inspections: Conducting thorough inspections of raw materials, work-in-progress, and finished products.

- Testing and Validation: Performing tests to verify the bolts meet the required strength, durability, and dimensional accuracy.

- Continuous Improvement: Regularly reviewing and enhancing quality control processes to improve consistency.

- Customer Feedback: Using customer feedback to identify areas for improvement and address any concerns promptly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bolt Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bolt Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bolt Makers are responsible for the production of bolts, which are essential fasteners used in various industries. Their primary duties include:

1. Bolt Production

Bolt Makers operate bolt-making machines to produce bolts of various sizes and specifications. They ensure that the bolts meet the required dimensions, strength, and quality standards.

- Set up and calibrate bolt-making machines

- Load raw materials into the machines

- Monitor the production process and make adjustments as needed

- Inspect finished bolts for defects and quality

2. Raw Material Handling

Bolt Makers handle raw materials such as wire rods or bars. They load the materials into the bolt-making machines and ensure that the materials are of the correct specifications.

- Load raw materials into the machines

- Inspect raw materials for defects

- Store raw materials safely

3. Machine Maintenance

Bolt Makers perform basic maintenance on bolt-making machines. They clean, lubricate, and adjust the machines to ensure optimal performance.

- Clean and lubricate machines

- Adjust machines to maintain production efficiency

- Report any maintenance issues to supervisors

4. Quality Control

Bolt Makers inspect finished bolts for defects and quality. They use measuring tools and gauges to ensure that the bolts meet the required specifications.

- Inspect finished bolts for defects

- Measure bolts to ensure they meet specifications

- Sort and package bolts based on quality

Interview Tips

To prepare for a Bolt Maker interview, candidates should consider the following tips:

1. Research the Company and Industry

Research the company and the industry to gain an understanding of their operations and the role of a Bolt Maker within that context. This will help you tailor your answers to the specific requirements of the position.

- Visit the company’s website and social media pages

- Read industry publications and articles

- Attend industry events and conferences

2. Practice Common Interview Questions

Practice answering common interview questions related to your skills, experience, and qualifications. Develop clear and concise responses that highlight your strengths and abilities as a Bolt Maker.

- Describe your experience operating bolt-making machines

- Explain how you ensure the quality of bolts

- Give an example of a time you solved a problem with a bolt-making machine

3. Showcase Your Knowledge of the Industry

Bolt Makers should demonstrate their knowledge of the industry and the latest technologies used in bolt production. This shows your commitment to staying up-to-date with industry trends and practices.

- Discuss recent advancements in bolt-making technology

- Share your thoughts on industry best practices

- Explain how you stay informed about the latest industry news

4. Highlight Your Commitment to Quality

Bolt Makers should emphasize their commitment to producing high-quality bolts. Describe your attention to detail and your ability to meet or exceed quality standards.

- Share examples of your quality control procedures

- Discuss your experience with industry quality standards

- Explain how you maintain a clean and organized work area

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bolt Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!