Feeling lost in a sea of interview questions? Landed that dream interview for Circular Head Saw Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Circular Head Saw Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

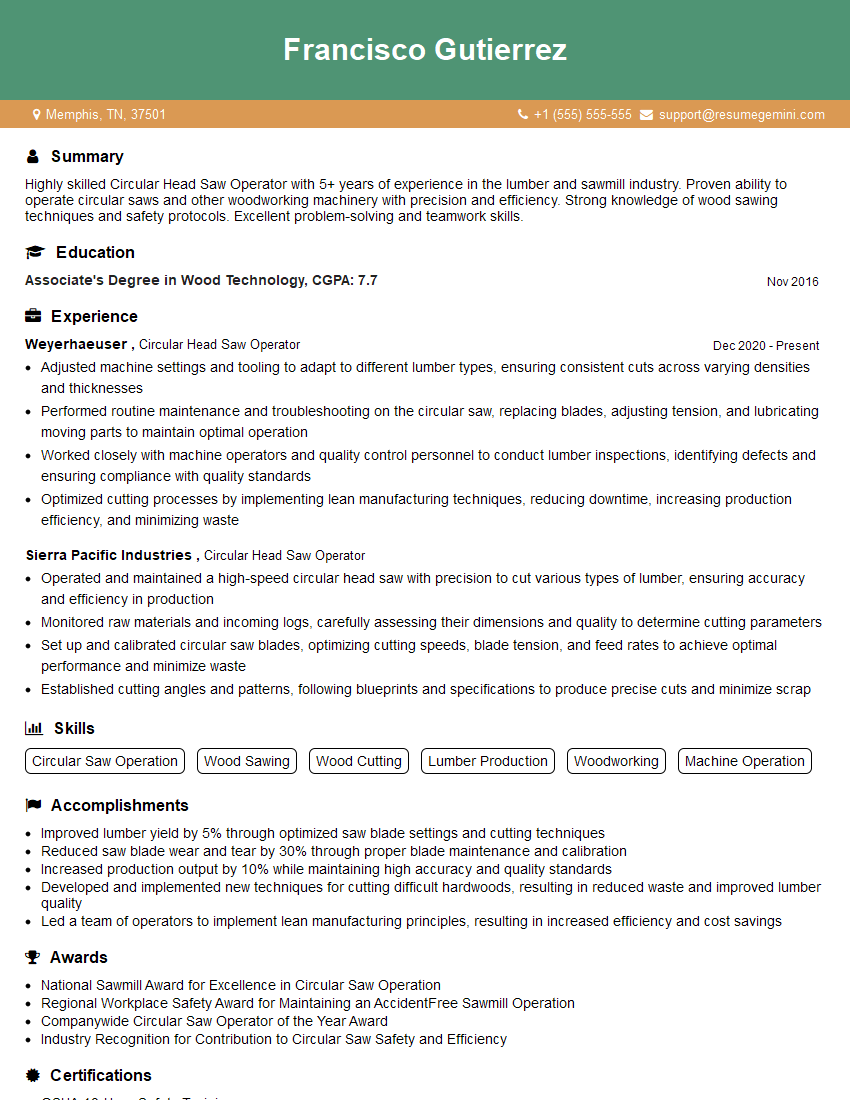

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Circular Head Saw Operator

1. How would you ensure that the circular saw blade is properly aligned and tensioned?

To ensure proper alignment and tension of the circular saw blade, I follow these steps:

- Alignment: I use a dial indicator to check the blade’s alignment with the saw table and adjust the blade’s position using the saw’s built-in alignment mechanisms.

- Tension: I refer to the manufacturer’s specifications for the recommended tension for the blade size and material. Using a tension wrench, I tighten the blade to the appropriate level.

2. What safety precautions do you take when operating a circular head saw?

To ensure safety when operating a circular head saw, I adhere to the following precautions:

Proper Attire:

- Wear snug-fitting, non-restrictive clothing.

- Use appropriate safety glasses and hearing protection.

Machine Inspection:

- Check the saw for proper grounding and blade guard functionality.

- Ensure the saw is stable and free of any loose parts.

Material Handling:

- Securely clamp the workpiece to the saw table.

- Use push sticks to guide material through the blade.

3. Can you describe the different types of circular saw blades and their applications?

There are several types of circular saw blades, each designed for specific applications:

Crosscut Blades:

- Intended for cutting across the grain.

- Have fewer teeth with larger gullets to efficiently remove sawdust.

Ripping Blades:

- Used for cutting with the grain.

- Feature more teeth with smaller gullets to provide a smooth cut.

Combination Blades:

- Versatile blades designed for both crosscutting and ripping.

- Have a combination of tooth shapes and sizes.

4. How do you determine the correct feed rate for a circular saw?

To determine the optimal feed rate for a circular saw, I consider several factors:

- Blade type: Crosscut blades require a faster feed rate than ripping blades.

- Material thickness: Thicker materials need a slower feed rate.

- Hardness of material: Harder materials require a slower feed rate.

- Saw power: More powerful saws can handle higher feed rates.

By adjusting the feed rate appropriately, I ensure efficient cutting and prevent blade damage.

5. How do you maintain and troubleshoot a circular head saw?

To maintain and troubleshoot a circular head saw, I follow these steps:

Regular Maintenance:

- Clean the saw regularly to remove sawdust and debris.

- Lubricate the saw’s moving parts as per the manufacturer’s instructions.

- Inspect the blade for wear or damage and replace it if necessary.

Troubleshooting:

- Blade binding: Check for dull or damaged blades, insufficient feed rate, or misaligned material.

- Excessive vibration: Ensure the saw is stable, the blade is properly tensioned, and the workpiece is securely clamped.

- Sparks during cutting: Adjust the feed rate, check for blade dullness, or consider using a different blade type.

6. Can you explain the concept of kerf and how it affects cutting operations?

Kerf refers to the width of the cut produced by a circular saw blade:

- Blade thickness: Thicker blades create a wider kerf.

- Blade design: Blades with more teeth per inch (TPI) produce a narrower kerf.

A wider kerf can affect the accuracy and efficiency of cutting operations, so selecting the appropriate blade for the desired cut is crucial.

7. What factors influence the quality of a cut made by a circular saw?

Several factors impact the quality of a cut made by a circular saw:

- Blade sharpness: Dull blades produce ragged cuts.

- Blade type: Crosscut blades provide cleaner cuts than ripping blades.

- Feed rate: Too fast or too slow feed rates can affect cut quality.

- Material type: Harder materials require slower feed rates and sharper blades.

- Saw stability: A stable saw ensures more precise cuts.

8. How do you handle different types of wood while using a circular saw?

Handling different wood types requires specific adjustments:

Hardwoods:

- Use sharp blades and a slower feed rate.

- Consider using a scoring blade for cleaner cuts.

Softwoods:

- Use blades with more TPI for a smoother finish.

- Maintain a faster feed rate.

Plywood:

- Use blades designed for plywood to prevent chipping.

- Support the plywood well to avoid splintering.

9. Describe the importance of using proper dust collection when operating a circular saw.

Proper dust collection is crucial for:

- Health and safety: Sawdust can cause respiratory issues and irritate eyes.

- Machine maintenance: Dust accumulation can damage saw components.

- Work environment: Excessive dust can obstruct visibility and make the work area hazardous.

Using effective dust collection systems, such as dust extractors or vacuums, is essential to maintain a clean and safe work environment.

10. How do you ensure the accuracy of cuts made with a circular saw?

To ensure accurate cuts, I employ the following techniques:

- Using a straight edge or guide: This provides a reference for the saw to follow.

- Measuring and marking: I carefully measure and mark the desired cut lines.

- Feathering the saw: I start the cut slowly and gradually increase the pressure to avoid chipping.

- Practice: Regular practice and experience improve accuracy.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Circular Head Saw Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Circular Head Saw Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Circular Head Saw Operators are responsible for operating, maintaining, and troubleshooting circular head saws, used for cutting a variety of materials. Their key job responsibilities include:

1. Cutting Operations

Operate circular head saws to cut materials such as wood, plastic, and metal to specified dimensions and shapes.

- Select and install appropriate saw blades based on material type and cutting requirements.

- Adjust machine settings, including blade height, speed, and feed rate, to optimize cutting performance.

2. Material Handling

Load and unload materials onto the saw table, ensuring proper alignment and support.

- Secure materials using clamps or jigs to prevent movement during cutting.

- Monitor material flow and make adjustments as necessary to maintain production efficiency.

3. Equipment Maintenance

Perform daily and periodic maintenance tasks on circular head saws to ensure optimal performance and safety.

- Inspect saws, blades, and accessories for wear or damage.

- Lubricate and clean machinery as per manufacturer’s instructions.

- Troubleshoot minor malfunctions and perform basic repairs.

4. Quality Control

Monitor the cutting process to ensure product quality meets specifications.

- Inspect cut pieces for accuracy, dimensions, and finish.

- Make adjustments to machine settings or cutting techniques as needed to correct any deviations.

5. Safety and Compliance

Adhere to established safety procedures and regulations related to circular head saw operation.

- Wear appropriate personal protective equipment (PPE), such as eye protection, earplugs, and gloves.

- Follow lockout/tagout procedures when performing maintenance or repairs.

- Maintain a clean and organized work area to minimize hazards.

Interview Tips

To prepare for a Circular Head Saw Operator interview, candidates should focus on showcasing their technical skills, safety awareness, and attention to detail.

1. Research the Company and Role

Gather information about the company’s industry, products, and specific job requirements to tailor your answers accordingly.

- Examine the job description thoroughly to identify the key responsibilities and qualifications.

- Consider how your experience and skills align with the company’s needs.

2. Highlight Technical Proficiency

Demonstrate your expertise in operating and maintaining circular head saws, including:

- Blade selection and installation.

- Machine setup and adjustment.

- Troubleshoot cutting issues.

- Safety protocols and preventive maintenance techniques.

3. Emphasize Safety and Quality

Stress your understanding of safety procedures and your commitment to maintaining a safe work environment.

- Explain how you ensure proper PPE usage, follow lockout/tagout protocols, and maintain a clean work area.

- Highlight your ability to monitor cutting operations and implement quality control measures to meet specifications.

4. Showcase Attention to Detail

Emphasize your ability to perform precise cutting operations and inspect products for accuracy and quality.

- Provide examples of your attention to detail, such as using precision measuring tools or implementing quality control procedures.

- Explain how you handle deviations from specifications and ensure corrective actions are taken.

5. Practice Answering Common Questions

Prepare for typical interview questions tailored to this role, such as:

- Describe your experience in operating circular head saws.

- How do you ensure safe cutting practices in your work environment?

- Provide an example of a challenging cutting task you have successfully completed.

- How do you handle deviations from cutting specifications?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Circular Head Saw Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!