Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Gang Head Saw Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

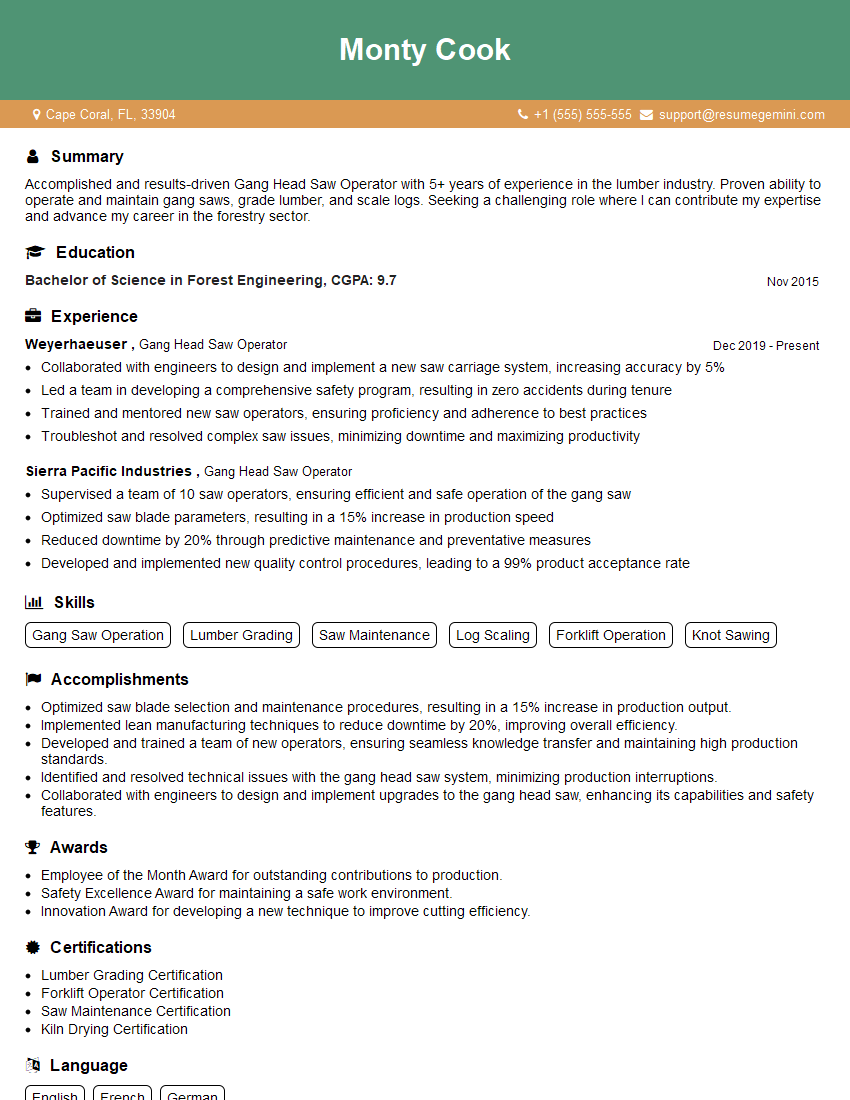

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Gang Head Saw Operator

1. Explain the process of setting up a gang head saw?

Setting up a gang head saw involves several steps to ensure accuracy and efficiency:

- Inspect and clean the saw: Verify the condition of the saw blades, bearings, and frame. Remove any debris or contaminants.

- Mount the saw blades: Install the appropriate saw blades onto the gang saw spindle, ensuring proper alignment and tension.

- Set the saw blade height and tilt: Adjust the saw blades to the desired cutting height and tilt based on the workpiece dimensions and cutting requirements.

- Set the feed speed: Determine the optimal feed rate based on the material type, thickness, and desired cut quality.

- Test the setup: Perform a test cut on a scrap piece to ensure the saw blades are cutting accurately and the workpiece is being fed at the correct speed.

2. Describe the factors that affect the quality of the cut made by a gang head saw?

Saw blade selection

- Blade material (e.g., carbide, HSS)

- Blade tooth geometry (e.g., pitch, gullet depth)

- Blade sharpness

Workpiece characteristics

- Material type (e.g., wood, metal)

- Thickness and density

- Surface condition

Saw operation parameters

- Feed speed

- Saw blade speed

- Cutting depth

Maintenance and calibration

- Regular blade sharpening and replacement

- Proper saw alignment and calibration

- Monitoring of feed rate and saw blade speed

3. How do you troubleshoot common problems encountered when operating a gang head saw?

- Blade chatter or vibration: Check for loose bolts or bearings, improper blade tension, or workpiece alignment issues.

- Excessive burring or tearing: Adjust saw blade speed, feed rate, or use a different blade with a finer tooth pitch.

- Burn marks or discoloration: Reduce feed rate or increase cutting speed, check for blade sharpness, or use a coolant.

- Incorrect cut dimensions: Verify saw blade alignment, workpiece positioning, or reset feed speed.

- Mechanical failures: Inspect saw frame, spindle, or other components for damage or wear, and contact a qualified technician for repairs.

4. What are the safety precautions to observe when working with a gang head saw?

- Wear appropriate safety gear (e.g., eye protection, earplugs, gloves)

- Ensure the saw is properly grounded and guarded.

- Keep hands and fingers away from moving parts.

- Never operate the saw while under the influence of drugs or alcohol.

- Inspect the saw and blades regularly for any damage or defects.

- Follow manufacturer’s operating instructions and guidelines.

5. How do you maintain and calibrate a gang head saw to ensure optimal performance?

Maintaining and calibrating a gang head saw is essential for its efficient and accurate operation:

- Regular cleaning and lubrication: Remove debris from the saw frame, spindle, and blades, and apply lubricant to moving parts.

- Blade sharpening and replacement: Sharpen or replace saw blades as needed to maintain their cutting edge.

- Alignment and calibration: Check and adjust the saw blade alignment, spindle runout, and feed speed to ensure precise cutting.

- Tensioning: Regularly inspect and adjust the saw blade tension to prevent chatter and vibration.

- Follow manufacturer’s instructions: Refer to the manufacturer’s manual for specific maintenance and calibration procedures.

6. What troubleshooting steps would you take if the saw blade breaks during operation?

- Shut off the saw and disconnect power immediately: Ensure safety first.

- Inspect the broken blade: Determine the cause of failure (e.g., improper tension, dull blade, hitting a foreign object).

- Replace the broken blade: Install a new blade following proper setup procedures.

- Check for damage to the saw frame or spindle: Inspect these components for any impact or damage caused by the broken blade.

- Restart the saw and test: Once the new blade is installed, run a test cut to ensure the saw is operating properly.

7. Describe the techniques you use to maximize the efficiency and accuracy of a gang head saw?

- Proper blade selection: Choose saw blades with the appropriate tooth geometry and material for the workpiece and desired cut quality.

- Optimal feed rate: Determine the ideal feed rate based on the material type, thickness, and blade capabilities.

- Precision setup: Ensure accurate alignment of the saw blades, workpiece, and feed system.

- Maintenance and calibration: Regularly inspect and calibrate the saw to maintain peak performance.

- Optimized cutting parameters: Adjust saw blade speed, feed rate, and cutting depth based on the workpiece and desired results.

8. How do you manage multiple woodworking projects simultaneously while operating a gang head saw?

- Prioritization and planning: Establish a schedule and prioritize projects based on deadlines and resource availability.

- Efficient setups: Optimize saw setups to minimize changeover time between projects.

- Material preparation: Ensure materials are cut to size and organized for each project to streamline workflow.

- Continuous monitoring: Regularly check the progress of each project and adjust operations as needed.

- Effective communication: Coordinate with colleagues and supervisors to ensure seamless project execution.

9. What is the role of a gang head saw operator in ensuring workplace safety?

- Maintaining a clean and organized work area: Reduce trip and fall hazards.

- Inspecting equipment regularly: Check for any damage or defects that could pose risks.

- Following safety protocols: Adhere to established safety procedures, such as wearing proper PPE.

- Reporting potential hazards: Identify and report any unsafe conditions or practices to supervisors.

- Participating in safety training: Stay up-to-date on industry best practices and safety regulations.

10. How do you stay abreast of the latest advancements in gang head saw technology and techniques?

- Attending industry events and conferences: Network with experts and learn about new technologies.

- Reading industry publications and online resources: Stay informed about industry trends and best practices.

- Seeking training and certification: Enhance skills and knowledge through formal training programs.

- Collaborating with colleagues: Share knowledge and experiences with other gang head saw operators.

- Consulting with manufacturers and suppliers: Stay updated on the latest advancements and product developments.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Gang Head Saw Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Gang Head Saw Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Gang Head Saw Operator is answerable to oversee the operation of sawing machines and ensure the production of quality lumber. Their duties include:

1. Machine Operation and Maintenance

Setup and run different sawing machines, such as head saws, circular saws, and resaws.

- Operate machines at the correct speeds and settings.

- Maintain machines and make adjustments as needed.

- Troubleshoot and repair machine problems.

2. Lumber Quality Control

Monitor the quality of lumber being produced.

- Inspect lumber for defects, such as knots, cracks, and splits.

- Make adjustments to the sawing process to improve lumber quality.

- Grade and sort lumber according to the company’s standards.

3. Production

Supervise and assist a team of saw operators to optimize the production of lumber.

- Ensure the team meets production quotas.

- Train and develop saw operators.

- Assist with the planning and scheduling of production.

4. Safety

Make sure the work environment is safe for employees.

- Enforce safety rules and regulations.

- Conduct safety training for employees.

- Inspect equipment for potential hazards.

Interview Tips

Preparing thoroughly for a job interview can significantly increase your chances of success. Here are some tips to help you ace the interview for a Gang Head Saw Operator position:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and services. Also, read the job description carefully to gain a clear understanding of the duties and responsibilities of a Gang Head Saw Operator.

- Find out about their sustainability practices and safety record if those matter to you.

- Prepare questions to ask the interviewer which demonstrate your interest and knowledge of the company.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in your resume and cover letter. When answering interview questions, use specific examples to illustrate your abilities.

- Quantify your accomplishments whenever possible. For example, instead of saying, “I managed a team of saw operators,” you could say, “I led a team of six saw operators, resulting in a 15% increase in production.”

- If you have experience with specific types of sawing machines, be sure to mention them.

3. Practice Common Interview Questions

Many common interview questions are asked in almost every job interview.

- These questions include things like, “Why are you interested in this position? and “What are your strengths and weaknesses?”

- Prepare thoughtful and concise answers to these questions. You can also practice answering them out loud.

4. Dress Professionally and Be on Time

Your appearance and punctuality will make a positive impression on the interviewer. Dress professionally and arrive for your interview on time.

- If you have long hair, tie it back or wear it in a neat style.

- Avoid wearing cologne or perfume, as some people may be allergic to them.

5. Be Enthusiastic and Positive

A positive attitude will go a long way in an interview. Be enthusiastic about the position and the company.

- Smile and make eye contact with the interviewer.

- Speak clearly and confidently.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Gang Head Saw Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Gang Head Saw Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.