Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Automatic Profile Shaper Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

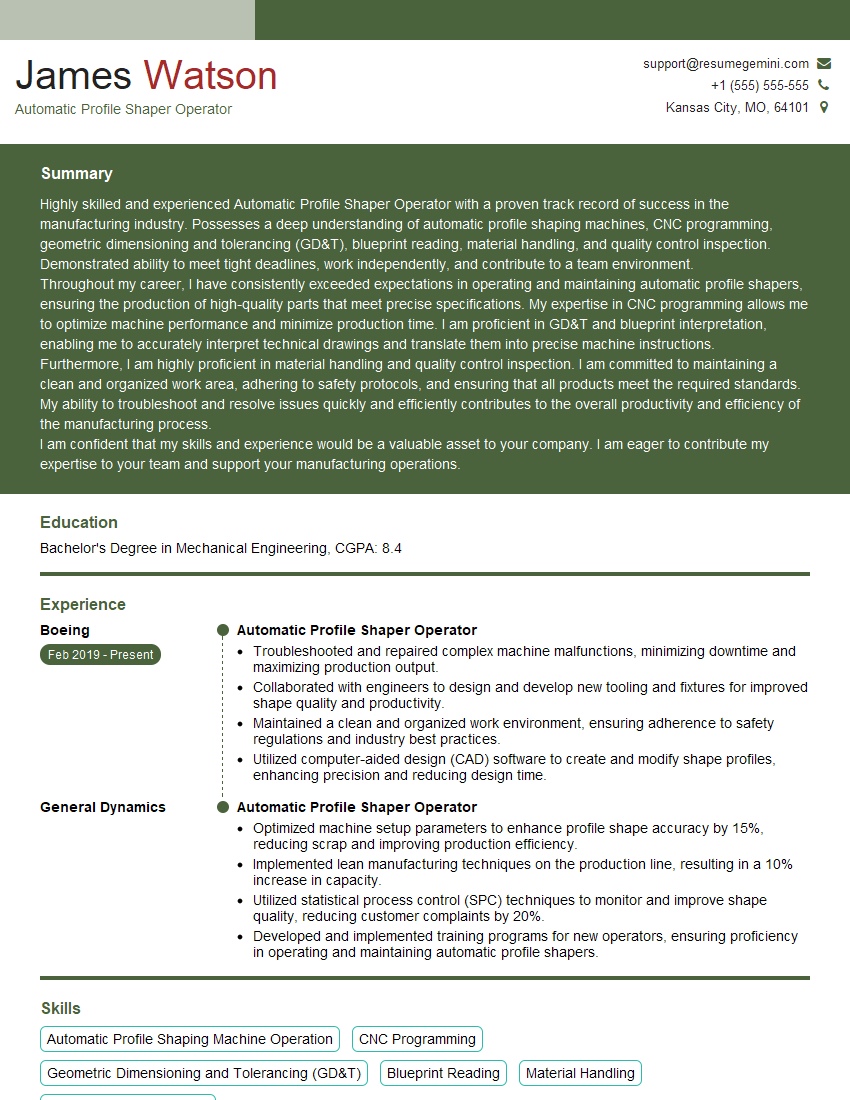

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automatic Profile Shaper Operator

1. Describe the basic principles of operation of an Automatic Profile Shaper?

An Automatic Profile Shaper is a machine tool that uses a rotating cutter to shape the profile of a workpiece. The workpiece is held in a fixture, and the cutter is moved along the desired profile path. The cutter is usually made of carbide or diamond, and the workpiece is usually made of metal or plastic.

- The machine is controlled by a computer, which reads the profile path from a CAD file.

- The computer then generates a series of commands that move the cutter along the path.

- The cutter is rotated at a high speed, and the workpiece is fed into the cutter at a controlled rate.

- The result is a workpiece that has been shaped to the desired profile.

2. What are the different types of Automatic Profile Shapers?

Vertical Profile Shapers

- The cutter is mounted on a vertical spindle.

- The workpiece is held on a table that moves in the X and Y axes.

- This type of shaper is used for shaping flat or slightly curved profiles.

Horizontal Profile Shapers

- The cutter is mounted on a horizontal spindle.

- The workpiece is held on a table that moves in the X and Z axes.

- This type of shaper is used for shaping complex profiles.

3. What are the key factors to consider when selecting an Automatic Profile Shaper?

- The size of the workpiece

- The complexity of the profile

- The desired accuracy

- The budget

4. What are the different types of cutters used in Automatic Profile Shapers?

Single-point cutters

- These cutters have a single cutting edge.

- They are used for shaping simple profiles.

Multi-point cutters

- These cutters have multiple cutting edges.

- They are used for shaping complex profiles.

5. What are the different types of fixtures used in Automatic Profile Shapers?

Mechanical fixtures

- These fixtures use clamps or screws to hold the workpiece in place.

- They are simple to use and inexpensive.

Vacuum fixtures

- These fixtures use a vacuum to hold the workpiece in place.

- They are more expensive than mechanical fixtures, but they can be used to hold workpieces of any shape.

6. What are the different types of controls used in Automatic Profile Shapers?

Manual controls

- These controls allow the operator to manually move the cutter and the workpiece.

- They are simple to use, but they require a skilled operator.

CNC controls

- These controls use a computer to control the movement of the cutter and the workpiece.

- They are more expensive than manual controls, but they can produce more accurate and consistent results.

7. What is the difference between a profile shaper and a milling machine?

- Profile shapers are used to shape the profile of a workpiece.

- Milling machines are used to cut flat surfaces into a workpiece.

- Profile shapers typically have a single cutting edge, while milling machines typically have multiple cutting edges.

- Profile shapers are typically used for low-volume production, while milling machines are typically used for high-volume production.

8. What are the safety precautions that must be taken when operating an Automatic Profile Shaper?

- Wear appropriate safety gear, including safety glasses, gloves, and a dust mask.

- Keep the work area clean and free of debris.

- Make sure the machine is properly grounded.

- Never operate the machine without the guard in place.

- Be aware of the moving parts of the machine.

9. What are the maintenance procedures that must be performed on an Automatic Profile Shaper?

- Clean the machine regularly.

- Lubricate the moving parts regularly.

- Inspect the cutter and the fixture regularly.

- Calibrate the machine regularly.

10. What are the troubleshooting tips for Automatic Profile Shapers?

- If the machine is not cutting properly, the cutter may be dull or damaged.

- If the workpiece is not being held securely, the fixture may be loose.

- If the machine is making excessive noise, the bearings may be worn.

- If the machine is not moving smoothly, the drive belt may be loose or damaged.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automatic Profile Shaper Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automatic Profile Shaper Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Automatic Profile Shaper Operator plays a crucial role in the manufacturing process, operating and maintaining advanced machinery to create precise profiles on metal components. Their key responsibilities include:

1. Machine Operation and Setup

Setting up and operating automatic profile shapers to cut and shape metal parts according to specified dimensions and tolerances.

2. Tooling and Fixture Maintenance

Inspecting, cleaning, and replacing cutting tools and fixtures to ensure optimal performance and precision.

3. Quality Assurance and Inspection

Performing quality checks on finished parts using measuring instruments and ensuring they meet required specifications.

4. Preventive Maintenance

Conducting regular maintenance tasks on the machine, including lubrication, cleaning, and minor repairs, to prevent breakdowns and maintain efficiency.

Interview Tips

To ace the interview for an Automatic Profile Shaper Operator position, candidates should consider the following tips:

1. Research the Company and Industry

Understand the company’s background, products, and industry trends. This demonstrates your interest and preparation.

2. Highlight Relevant Experience

Emphasize your previous experience with automatic profile shapers or similar machines. Quantify your accomplishments with specific examples.

3. Demonstrate Technical Skills

Showcase your knowledge of machine operation, tooling, and quality control procedures. Provide examples of how you have solved technical problems.

4. Emphasize Precision and Attention to Detail

Highlight your ability to work precisely and meet tight tolerances. Explain how you ensure the quality of your work.

5. Prepare for Common Interview Questions

Research common interview questions for this role, such as those related to machine setup, safety, and troubleshooting. Practice your answers to present yourself confidently.

6. Ask Informed Questions

Asking thoughtful questions about the role, company, or industry shows your engagement and interest. This also gives the interviewer an opportunity to assess your curiosity.

7. Follow Up Professionally

Send a thank-you note to the interviewer within 24 hours, expressing your appreciation and reiterating your interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Automatic Profile Shaper Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.