Feeling lost in a sea of interview questions? Landed that dream interview for Barrel Lathe Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Barrel Lathe Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

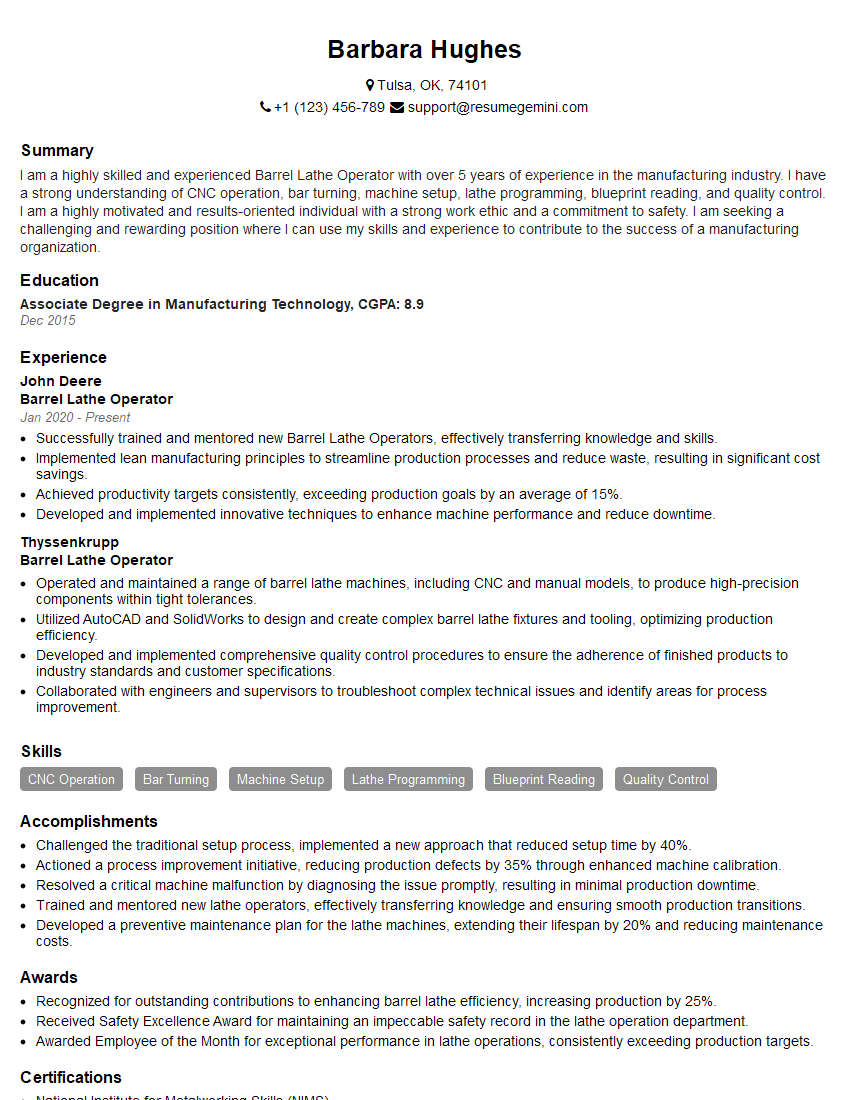

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Barrel Lathe Operator

1. Describe the process of setting up a barrel lathe machine for a specific part.

Answer: The process of setting up a barrel lathe machine for a specific part involves the following steps:

- Select and install the appropriate tooling: This includes the correct cutting tools, collets, and workholding devices.

- Load the material: Place the material to be machined into the lathe’s chuck or collet.

- Align the workpiece: Use the machine’s controls to align the workpiece with the cutting tool.

- Set the cutting parameters: Determine and set the appropriate spindle speed, feed rate, and depth of cut based on the material and desired finish.

- Run a test cut: Perform a short test cut to verify the setup and cutting parameters before starting full production.

2. How do you ensure that the parts produced on the barrel lathe meet the required specifications?

Answer: To ensure that parts produced on the barrel lathe meet the required specifications, I follow these practices:

- Regular machine calibration and maintenance: Calibrate the machine regularly to maintain accuracy and prevent errors.

- Use of precision measuring tools: Utilize calipers, micrometers, and other measuring tools to verify the dimensions of the parts.

- Inspection during operation: Monitor the cutting process and inspect parts at regular intervals to catch any deviations.

- Implementation of statistical process control (SPC): Collect and analyze data to identify and eliminate sources of variation.

- Adherence to established quality standards: Follow industry standards and company protocols to ensure consistency and quality.

3. Explain the different types of cutting tools used on a barrel lathe.

Answer: There are various types of cutting tools used on a barrel lathe, each with specific applications:

- Turning tools: Used for external and internal turning operations, removing material to create cylindrical or tapered shapes.

- Boring tools: Designed to enlarge existing holes or create new ones.

- Facing tools: Used to create flat surfaces perpendicular to the lathe’s axis.

- Threading tools: Used for cutting threads on the workpiece.

- Knurling tools: Create a diamond or straight pattern on the workpiece surface.

4. How do you handle and prevent common problems that may occur during barrel lathe operations?

Answer: Common problems during barrel lathe operations and my strategies to handle and prevent them include:

- Chattering: Occurs due to excessive vibration. I adjust the cutting parameters, use sharp tools, and ensure the workpiece is properly secured.

- Tool breakage: Caused by using blunt or incorrect tools. I inspect tools regularly, select the appropriate materials, and apply cutting lubricants.

- Surface finish issues: Resulting from worn tools or improper cutting conditions. I maintain tool sharpness, optimize cutting parameters, and use coolant.

- Dimensional errors: Arising from machine calibration issues or operator errors. I calibrate the machine regularly, follow setup procedures carefully, and use precision measuring instruments.

- Safety hazards: I prioritize safety by wearing proper gear, following protocols, and maintaining a clean work environment.

5. Describe the safety protocols that you follow when operating a barrel lathe.

Answer: I adhere to the following safety protocols when operating a barrel lathe:

- Wear appropriate safety gear: Safety glasses, gloves, and appropriate clothing.

- Secure the workpiece properly: Use chucks, collets, or other workholding devices to prevent workpiece slippage.

- Inspect the machine and tools: Check for any damage or defects before operation.

- Maintain a clean work area: Remove debris and spills to prevent tripping hazards.

- Follow proper setup procedures: Ensure the machine is properly adjusted and calibrated.

- Be aware of surroundings: Pay attention to other operators and equipment in the area.

6. How do you maintain and troubleshoot a barrel lathe machine?

Answer: I perform regular maintenance and troubleshooting on barrel lathe machines to ensure optimal performance and prevent breakdowns:

- Regular maintenance: Clean and lubricate the machine regularly, replace worn or damaged components, and check for any loose connections.

- Troubleshooting: In case of any issues, I check for error messages, inspect components for wear or damage, and consult technical manuals or consult with experienced technicians.

- Calibration and alignment: Regularly calibrate the machine to ensure accuracy and alignment of the spindle, chuck, and tailstock.

- Use of specialized tools: I utilize specialized tools such as dial indicators, micrometers, and vibration analyzers for accurate measurements and troubleshooting.

7. Explain the concept of feed rate and how it affects the machining process on a barrel lathe.

Answer: Feed rate refers to the rate at which the cutting tool advances along the workpiece during the machining process:

- Impact on surface finish: A higher feed rate can result in a rougher surface finish, while a lower feed rate produces a finer finish.

- Machining time: Increasing the feed rate can reduce machining time, but it can also increase the load on the machine and cutting tool.

- Tool wear: Excessive feed rates can lead to rapid wear of the cutting tool, reducing its lifespan.

- Material considerations: The feed rate must be adjusted based on the material being machined, with harder materials requiring lower feed rates.

8. Describe the different types of materials that can be machined on a barrel lathe.

Answer: A barrel lathe can machine a wide variety of materials, including:

- Metals: Steel, aluminum, brass, copper, titanium, and alloys.

- Plastics: Acrylic, polycarbonate, nylon, and polyethylene.

- Wood: Hardwoods, softwoods, and engineered wood products.

- Composites: Fiberglass, carbon fiber, and other composite materials.

- Other materials: Bone, ivory, and specialized materials for specific applications.

9. How do you calculate the spindle speed for a given cutting operation on a barrel lathe?

Answer: To calculate the spindle speed (N) for a given cutting operation on a barrel lathe, the following formula is used:

- N = (12 x V) / (π x D)

- Where:

- N = spindle speed in revolutions per minute (RPM)

- V = cutting speed in meters per minute (m/min)

- D = workpiece diameter in millimeters (mm)

- π = mathematical constant approximately equal to 3.14

10. Describe the process of operating a barrel lathe in both manual and CNC modes.

Answer: Operating a barrel lathe in manual mode involves manually controlling the machine’s movements and settings:

- Manual mode: The operator uses handwheels or levers to move the cutting tool and adjust the spindle speed and feed rate.

- CNC mode: Computerized numerical control (CNC) allows the machine to be programmed with specific instructions, enabling automated operation.

- Advantages of CNC: Increased precision, repeatability, and productivity compared to manual operation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Barrel Lathe Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Barrel Lathe Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Barrel Lathe Operators are responsible for operating and maintaining barrel lathes and other related equipment in the workplace. They ensure that the equipment is running smoothly and efficiently, and that the products being produced meet the required specifications. Some of the key job responsibilities of a Barrel Lathe Operator include:

1. Operating Barrel Lathes

Barrel Lathe Operators are responsible for setting up and operating barrel lathes. This involves tasks such as loading and unloading workpieces, selecting and installing the appropriate tooling, and setting the correct cutting parameters. The operator must also monitor the lathe during operation to ensure that it is running properly and that the workpiece is being machined to the correct specifications.

2. Maintaining Barrel Lathes

Barrel Lathe Operators are also responsible for maintaining their equipment. This involves tasks such as cleaning and lubricating the lathe, inspecting and replacing worn parts, and performing minor repairs. The operator must also keep a log of all maintenance performed on the lathe.

3. Troubleshooting Problems

Barrel Lathe Operators may encounter problems with their equipment from time to time. It is the operator’s responsibility to troubleshoot these problems and make repairs if possible. If the operator is unable to repair the problem, they must report it to their supervisor.

4. Producing Quality Products

Barrel Lathe Operators are responsible for producing quality products. This means that the operator must ensure that the workpieces are machined to the correct specifications and that they meet the required quality standards.

Interview Tips

To ace the interview for a Barrel Lathe Operator position, it is important to prepare thoroughly. Here are some tips to help you prepare:

1. Research the Company and the Position

Before the interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, and it will also help you to prepare for the specific questions that you may be asked during the interview.

2. Prepare for Common Interview Questions

There are a number of common interview questions that you are likely to be asked during an interview for a Barrel Lathe Operator position. These questions may include:

- Tell me about your experience operating barrel lathes.

- What are your strengths and weaknesses as a Barrel Lathe Operator?

- What are your goals for this position?

- Why are you interested in working for this company?

3. Practice Your Answers

Once you have prepared for the common interview questions, it is important to practice your answers. This will help you to feel more confident and prepared during the actual interview.

4. Dress Professionally

It is important to dress professionally for an interview for a Barrel Lathe Operator position. This shows the interviewer that you are serious about the job and that you are committed to making a good impression.

5. Be Yourself

The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

Next Step:

Now that you’re armed with the knowledge of Barrel Lathe Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Barrel Lathe Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini