Are you gearing up for a career in Box Blank Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Box Blank Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

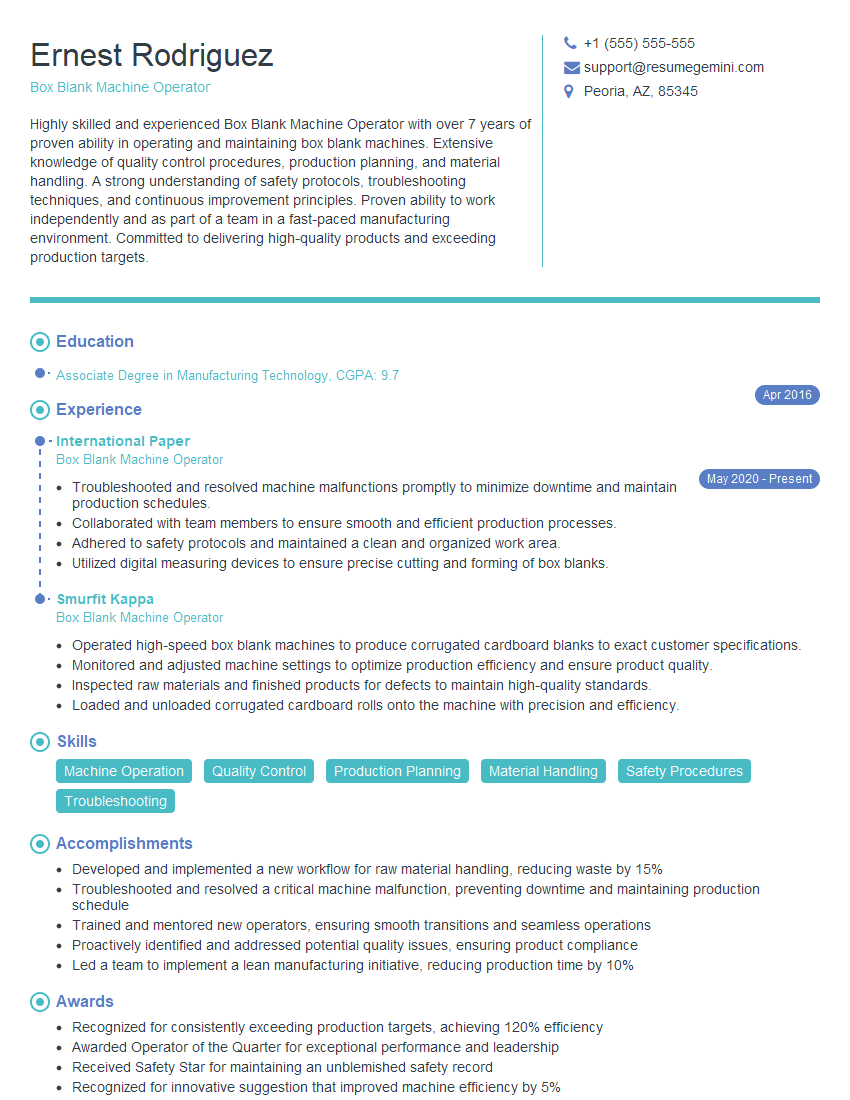

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Box Blank Machine Operator

1. What are the key responsibilities of a Box Blank Machine Operator?

As a Box Blank Machine Operator, my primary responsibilities encompass:

- Operating and monitoring Box Blank Machine to produce high-quality blanks

- Setting up and adjusting machine parameters, including cutting, creasing, and slitting operations

- Inspecting blanks for quality assurance and making necessary adjustments

- Maintaining a clean and organized work area, adhering to safety protocols

- Troubleshoot and resolve any technical issues or machine malfunctions promptly

2. Describe the different types of paper and paperboard used in Box Blank Machine operations?

Paperboard Types

- Solid Board: Multi-ply board known for strength and rigidity

- Corrugated Board: Consists of a fluted medium sandwiched between paperboard liners

Paper Types

- Kraft Paper: Durable and resistant to tearing

- Coated Paper: Provides a smooth surface for printing

- Recycled Paper: Eco-friendly option made from recycled materials

3. How do you ensure the accurate cutting and creasing of blanks on the Box Blank Machine?

To ensure precise cutting and creasing, I follow these steps:

- Proper Machine Setup: Calibrate cutting tools, adjust blade height, and set creasing depth accurately

- Material Preparation: Check paperboard condition and moisture content to prevent tearing or jamming

- Test Runs: Conduct trial runs to verify settings and make necessary adjustments

- Regular Maintenance: Sharpen blades, clean cutting dies, and lubricate moving parts to maintain optimal performance

4. What are the common quality control checks performed on Box Blanks?

I conduct thorough quality control checks on Box Blanks to ensure they meet specifications:

- Dimensions: Verify the length, width, and height of blanks using measuring tools

- Crease Quality: Examine creases for sharpness, accuracy, and absence of cracking

- Cut Quality: Inspect for clean cuts, no tearing or burrs

- Board Condition: Check for any imperfections, damage, or moisture issues

5. How do you handle machine malfunctions or breakdowns during Box Blank production?

When machine malfunctions occur, I follow a structured process:

- Immediate Response: Identify the issue and take immediate action to prevent further damage or downtime

- Troubleshooting: Analyze the problem, refer to manuals or consult with maintenance personnel

- Repair or Adjustment: Perform minor repairs or adjustments if possible, or contact maintenance for major issues

- Restart and Monitoring: Once resolved, restart the machine and monitor its performance to ensure it operates smoothly

6. Explain the importance of maintaining proper blade sharpness and its impact on Box Blank quality?

Sharp blades are crucial for high-quality Box Blanks:

- Precision Cutting: Sharp blades produce clean, precise cuts, preventing tearing or burrs

- Reduced Waste: Accurate cutting minimizes material waste and improves efficiency

- Crease Quality: Proper blade sharpness contributes to sharp and well-defined creases

- Machine Longevity: Dull blades put excessive strain on the machine, leading to wear and tear

7. How do you ensure the smooth operation and productivity of the Box Blank Machine?

I prioritize the following practices to maintain smooth operations:

- Regular Cleaning: Keep the machine clean to prevent paper dust buildup and ensure smooth movement

- Lubrication: Lubricate moving parts regularly to reduce friction and wear

- Daily Inspections: Conduct daily inspections to identify potential issues and address them promptly

- Operator Training: Ensure operators are well-trained and follow proper operating procedures

8. Describe the different types of box styles that can be produced on a Box Blank Machine?

Our Box Blank Machine is capable of producing a wide range of box styles:

- Regular Slotted Container (RSC): Standard box style with four flaps

- Full Overlap Container (FOL): Box with flaps that fully overlap

- Half Slotted Container (HSC): Box with two slotted flaps and two unslotted flaps

- Die-Cut Boxes: Boxes with custom shapes and designs created using dies

9. What are the safety protocols that you strictly adhere to while operating the Box Blank Machine?

Safety is paramount. I strictly follow these protocols:

- Personal Protective Equipment: Wear safety glasses, gloves, and appropriate clothing

- Machine Guarding: Ensure all guards and safety features are in place and operational

- Lockout/Tagout Procedures: Follow proper procedures when performing maintenance or repairs

- Emergency Stop Button: Be familiar with the location and operation of the emergency stop button

10. How do you stay updated with the latest advancements in Box Blank Machine technology?

To stay abreast of advancements:

- Attend Industry Conferences: Network with experts and learn about new technologies and best practices

- Read Trade Publications: Keep up with industry news and trends through journals and magazines

- Manufacturer Training: Participate in training sessions offered by Box Blank Machine manufacturers to enhance skills

- Online Resources: Explore websites and forums dedicated to Box Blank Machine technology

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Box Blank Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Box Blank Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Box Blank Machine Operators are responsible for the set-up and operation of box blank machines that produce cardboard boxes for various purposes such as packaging and storage. They ensure high-quality production, monitor equipment, and maintain a safe work environment.

1. Machine Operation

Operate box blank machines to convert cardboard sheets into flat or corrugated box blanks.

- Adjust and calibrate machine settings for different box sizes and specifications.

- Load and feed cardboard sheets into the machine.

- Monitor the production process, including speed, pressure, and temperature.

2. Quality Control

Ensure the quality of box blanks meets specifications.

- Inspect box blanks for defects such as cuts, tears, and misalignment.

- Make adjustments to the machine or process as needed.

3. Maintenance and Troubleshooting

Perform basic maintenance and troubleshooting tasks.

- Clean and lubricate machine components.

- Identify and resolve minor machine issues.

- Report major issues to supervisors.

4. Material Handling

Handle and transport cardboard sheets and box blanks safely and efficiently.

- Load and unload cardboard sheets from pallets.

- Stack and move box blanks to designated storage areas.

Interview Tips

Preparing thoroughly for a Box Blank Machine Operator interview is crucial to make a strong impression and increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to research the company and the specific Box Blank Machine Operator position you are applying for. This will give you insights into the company’s culture, values, and the requirements of the role.

- Visit the company website to learn about their products, services, and mission.

- Look into industry-specific publications and news articles to stay updated on the latest trends and technologies.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful and concise answers. Practice delivering your responses clearly and confidently.

- Prepare to discuss your experience in operating box blank machines.

- Highlight your knowledge of quality control procedures and troubleshooting techniques.

- Emphasize your attention to detail and ability to work in a fast-paced environment.

3. Dress Professionally

First impressions matter, so dress professionally for the interview. Choose attire that is clean, pressed, and appropriate for a manufacturing setting.

- Wear closed-toe shoes and comfortable pants that allow for movement.

- Avoid wearing loose clothing or jewelry that could pose a safety hazard.

4. Be Enthusiastic and Ask Questions

Show your enthusiasm for the position and the company during the interview. Ask thoughtful questions to demonstrate your interest and eagerness to learn more.

- Inquire about the company’s growth plans and opportunities for career advancement.

- Ask about the specific challenges and rewards of being a Box Blank Machine Operator in their organization.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Box Blank Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.