Feeling lost in a sea of interview questions? Landed that dream interview for Chucking and Boring Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Chucking and Boring Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

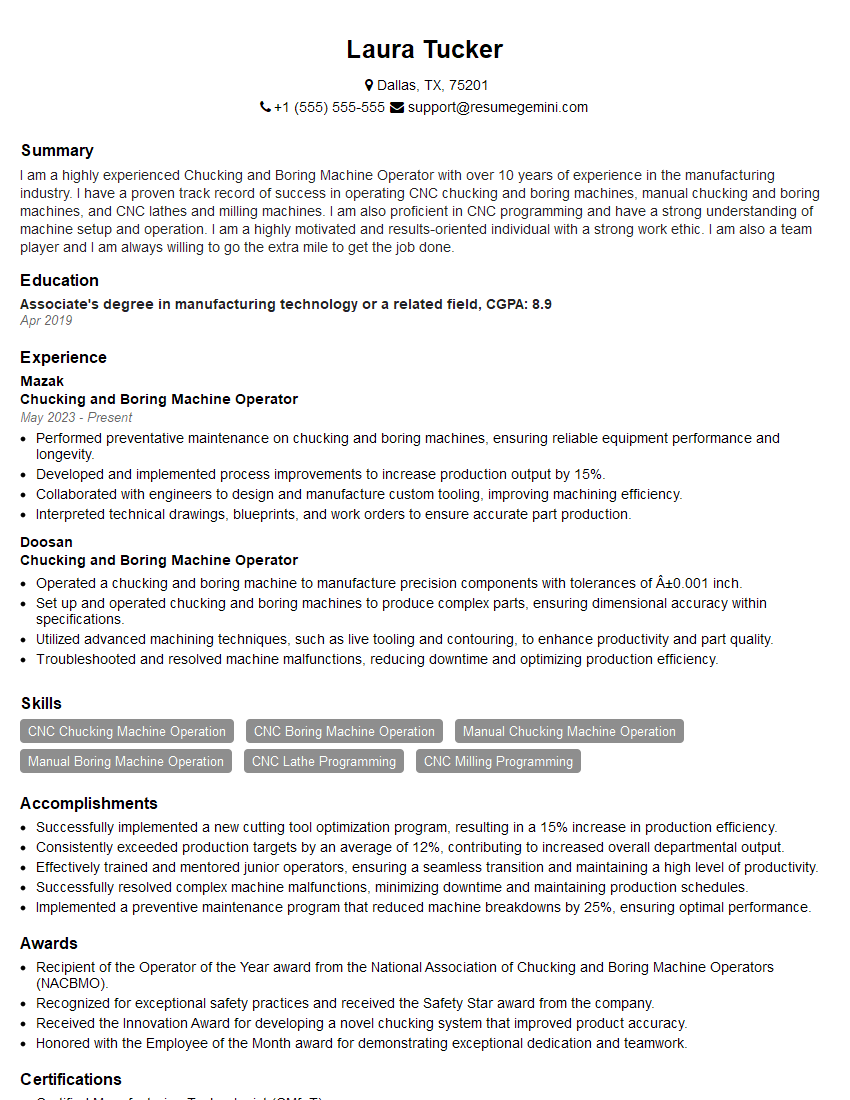

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chucking and Boring Machine Operator

1. What is the difference between chucking and boring a hole?

Chucking is the process of holding a workpiece in a chuck, while boring is the process of enlarging a hole that has already been drilled. Chucking is typically done on a lathe, while boring can be done on a lathe, a boring mill, or a horizontal boring machine.

2. What are the different types of chucking and boring tools?

Chucking tools

- Collet chucks

- Expanding mandrels

- Drawbar chucks

Boring tools

- Boring bars

- Boring heads

- Trepanning tools

3. What are the safety precautions that must be taken when chucking and boring a hole?

- Wear appropriate safety gear, including eye protection, hearing protection, and gloves.

- Inspect the chuck and boring tool before each use to ensure that they are in good condition.

- Securely fasten the workpiece in the chuck.

- Use the correct cutting speed and feed rate for the material being machined.

- Be aware of the potential for chips and coolant to be ejected from the machine.

4. What are the different types of materials that can be chucked and bored?

- Metals

- Plastics

- Wood

- Composites

5. What are the different applications for chucking and boring machines?

- Manufacturing

- Repair

- Prototyping

- Education

6. What are the advantages of using chucking and boring machines?

- High precision

- Versatility

- Efficiency

- Durability

7. What are the disadvantages of using chucking and boring machines?

- High cost

- Complexity

- Safety concerns

8. What are the trends in chucking and boring technology?

- Increased automation

- Improved cutting tools

- New materials

- Advanced software

9. What are the career opportunities for chucking and boring machine operators?

- Machinist

- Tool and die maker

- Manufacturing engineer

- Quality control inspector

10. What are the educational requirements for chucking and boring machine operators?

- High school diploma or equivalent

- Vocational training or apprenticeship

- Experience in machining

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chucking and Boring Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chucking and Boring Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Chucking and Boring Machine Operators play a critical role in the manufacturing industry, utilizing specialized machinery to produce high-precision components. Their responsibilities are diverse and demanding, requiring a comprehensive understanding of machining principles and a commitment to quality and safety.

1. Machine Operation and Setup

Chucking and Boring Machine Operators are responsible for setting up and operating chucking and boring machines according to engineering specifications. They must possess a deep understanding of these machines, including their capabilities and limitations.

- Configure and adjust the machine to specific operation requirements.

- Select and mount the appropriate cutting tools and accessories.

- Inspect and calibrate the machine to ensure accuracy and precision.

2. Material Handling and Inspection

Operators must be proficient in handling raw materials and finished products. They are also responsible for inspecting finished parts to verify conformance to specifications.

- Load and unload materials and parts from the machine.

- Inspect parts using gauging and measuring tools to ensure dimensional accuracy.

- Identify and rectify any deviations from specifications.

3. Process Optimization and Troubleshooting

Operators are expected to optimize production processes and troubleshoot any technical issues that may arise during operation.

- Monitor the machine’s performance and make adjustments to improve efficiency.

- Diagnose and resolve mechanical or software problems that affect machine operation.

- Coordinate with maintenance personnel to resolve complex issues.

4. Safety and Compliance

Safety is paramount in any manufacturing environment. Operators must adhere to established safety protocols and ensure compliance with workplace regulations.

- Follow safety procedures and wear appropriate protective gear.

- Maintain a clean and organized work area to minimize hazards.

- Report any unsafe conditions or practices to supervisors.

Interview Tips

Preparing for an interview for a Chucking and Boring Machine Operator position requires a multifaceted approach. Candidates must demonstrate not only their technical proficiency but also their problem-solving abilities and commitment to safety. Here are some tips to help you ace your interview:

1. Research the Company and Position

Familiarize yourself with the company’s background, values, and the specific requirements of the position. This will help you tailor your answers and demonstrate your understanding of the role.

- Visit the company’s website and social media pages.

- Review the job description thoroughly.

- Prepare questions that show your interest in the company and the position.

2. Highlight Your Technical Skills and Experience

Emphasize your proficiency in operating chucking and boring machines. Provide specific examples of your experience in setting up, operating, and troubleshooting these machines.

- Quantify your accomplishments whenever possible.

- Discuss any specialized training or certifications you have obtained.

- Be prepared to describe your problem-solving approach in detail.

3. Showcase Your Safety and Compliance Knowledge

Safety is a top priority in manufacturing. Highlight your commitment to following established safety protocols and maintaining a safe work environment.

- Describe your experience with safety procedures and regulations.

- Emphasize your attention to detail and ability to identify potential hazards.

- Explain how you promote a safety-conscious culture in the workplace.

4. Prepare Questions to Ask the Interviewer

Asking well-informed questions at the end of the interview demonstrates your interest in the position and the company. Prepare questions that are specific to the role and the industry.

- Ask about the company’s growth plans and future projects.

- Inquire about opportunities for professional development.

- Discuss the company’s safety record and initiatives.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Chucking and Boring Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.