Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cleat Maker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cleat Maker so you can tailor your answers to impress potential employers.

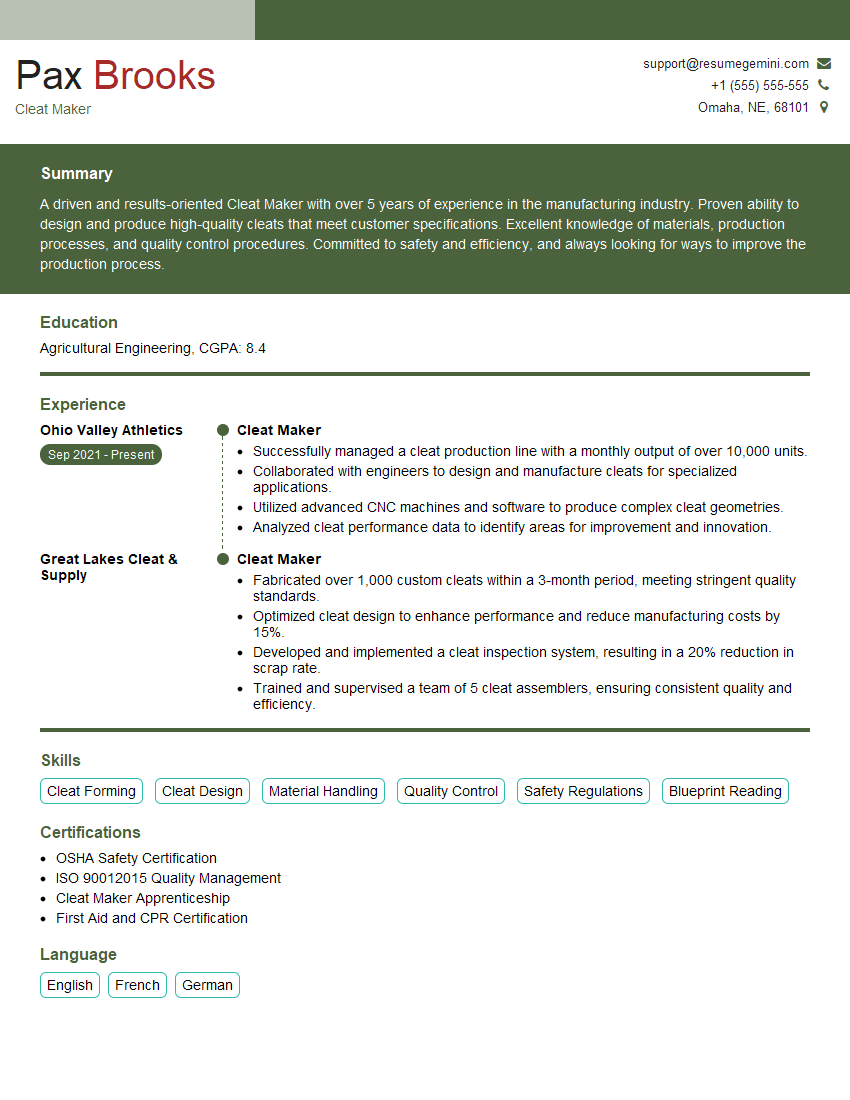

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cleat Maker

1. What are the different types of cleats used in footwear?

There are several types of cleats used in footwear, each designed for specific purposes and terrains. Some common types include:

- Screw-in cleats: These cleats are screwed into the sole of the footwear and provide excellent grip and stability on hard surfaces.

- Molded cleats: These cleats are molded directly into the sole of the footwear and offer good grip on a variety of surfaces.

- Detachable cleats: These cleats can be attached and detached from the footwear, allowing for quick changes depending on the conditions.

2. What are the key factors to consider when selecting the right cleats for a particular application?

Material

- The material of the cleats should be appropriate for the intended surface and activity. For example, metal cleats are suitable for hard surfaces, while rubber or plastic cleats are better for softer surfaces.

Shape and size

- The shape and size of the cleats can impact grip and traction. Larger cleats provide more stability, while smaller cleats offer greater flexibility.

Attachment method

- The attachment method determines how the cleats are secured to the footwear. Screw-in cleats provide the most secure attachment, while detachable cleats allow for easy adjustments.

3. What are the common materials used for making cleats?

The choice of material for cleats depends on the desired performance characteristics. Common materials include:

- Metal: Metal cleats, such as steel or aluminum, provide excellent traction and durability, but they can be heavy and noisy.

- Plastic: Plastic cleats are lightweight, flexible, and cost-effective, but they may not offer the same level of grip as metal cleats.

- Rubber: Rubber cleats offer good grip and shock absorption, making them suitable for sports that require agility and impact protection.

4. What are the manufacturing processes involved in producing cleats?

The manufacturing process for cleats typically includes:

- Material selection: The appropriate material is chosen based on the desired properties of the cleats.

- Molding or forging: The cleats are molded or forged into the desired shape and design.

- Heat treatment: Some cleats undergo heat treatment to enhance their strength and durability.

- Finishing: The cleats may be plated or coated to improve corrosion resistance or aesthetics.

5. What are the quality control measures implemented to ensure the performance and durability of cleats?

To ensure the quality of cleats, manufacturers typically implement several control measures:

- Material testing: The raw materials used are tested to meet specific standards and requirements.

- Production monitoring: The manufacturing process is closely monitored to ensure adherence to design specifications.

- Performance testing: Finished cleats undergo rigorous testing to evaluate their grip, stability, and durability.

6. Can you describe the differences between traditional and innovative cleat designs?

Traditional cleat designs have been used for a long time and offer reliable performance. However, innovative cleats have emerged to address specific needs and improve functionality.

Traditional cleats:

- Fixed shape and size

- Limited adjustability

- May be less efficient for certain activities

Innovative cleats:

- Adjustable shape and size

- Improved grip and traction

- Designed for specific sports or activities

7. What are the latest advancements in cleat technology?

The cleat industry is constantly evolving, with new advancements emerging to improve performance and comfort.

- 3D printing: 3D printing allows for the production of custom cleats with complex designs and optimized fit.

- Smart cleats: Smart cleats incorporate sensors and technology to track performance metrics and provide personalized feedback.

- Sustainable materials: Environmentally friendly materials are being used to reduce the impact of cleat production on the planet.

8. How do you stay up-to-date on the latest trends and developments in cleat design and manufacturing?

To stay informed about the latest advancements in the industry, I engage in several activities:

- Attending industry conferences and exhibitions

- Reading trade publications and journals

- Networking with professionals in the field

- Conducting research and exploring new technologies

9. What is your approach to problem-solving when it comes to cleat design and manufacturing?

When faced with a problem, I typically follow these steps:

- Identify the root cause of the issue

- Brainstorm potential solutions

- Evaluate the feasibility of each solution

- Implement the most effective solution

- Monitor and adjust as needed

10. How do you ensure that your cleats meet the specific requirements and expectations of customers?

To meet customer requirements, I prioritize the following:

- Understanding the customer’s needs through thorough discussions and research

- Designing and manufacturing cleats that align with the intended application and performance expectations

- Conducting rigorous testing to ensure that the cleats meet the desired standards

- Gathering feedback from customers and incorporating it into future designs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cleat Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cleat Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cleat Maker is responsible for ensuring the production of high-quality cleats for use in various industries, adhering to set standards and specifications.

1. Fabricate and Assemble Cleats

Using specialized tools and machinery, create cleats from raw materials, following established designs or specifications.

- Cut, shape, and form cleats from materials like metal, plastic, or composite.

- Assemble cleats by joining parts together using fasteners, adhesives, or welding techniques.

2. Inspect and Test Cleats

Conduct thorough inspections of finished cleats to ensure they meet quality standards and specifications.

- Verify dimensions, tolerances, and surface finish of cleats.

- Perform tests to evaluate the strength, durability, and performance of cleats.

3. Maintain and Repair Equipment

Maintain and repair equipment and machinery used in the production of cleats.

- Perform regular maintenance tasks such as lubrication, cleaning, and calibration.

- Identify and troubleshoot equipment malfunctions and make necessary repairs.

4. Ensure Health and Safety

Follow established health and safety procedures to maintain a clean and safe work environment.

- Wear appropriate personal protective equipment (PPE) and use safety equipment.

- Identify and eliminate potential hazards in the workplace.

Interview Tips

Preparing thoroughly can greatly increase your chances of success in a Cleat Maker interview. Consider the following tips to ace your interview:

1. Research the Company and Position

Familiarize yourself with the company’s background, products, and industry standing. Understand the specific requirements of the Cleat Maker role and the responsibilities involved.

- Visit the company website and social media pages.

- Read industry publications and news articles.

2. Highlight Relevant Skills and Experience

Tailor your resume and interview answers to emphasize the skills and experience required for the Cleat Maker position. Quantify your accomplishments whenever possible using specific examples.

- Showcase your abilities in fabricating, assembling, and inspecting cleats.

- Provide examples of your proficiency in using manufacturing equipment and tools.

3. Practice Common Interview Questions

Anticipate common interview questions and prepare your responses in advance. Practice delivering your answers clearly and concisely.

- Explain your experience in the cleat manufacturing industry.

- Describe your knowledge of cleat design and specifications.

4. Prepare Questions for the Interviewer

Asking thoughtful questions not only demonstrates your interest in the position but also allows you to gather additional information. Prepare a few questions related to the company, the role, or the industry.

- Inquire about the company’s growth plans and future projects.

- Ask about opportunities for professional development and training.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cleat Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!