Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted CNC Wood Lathe Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

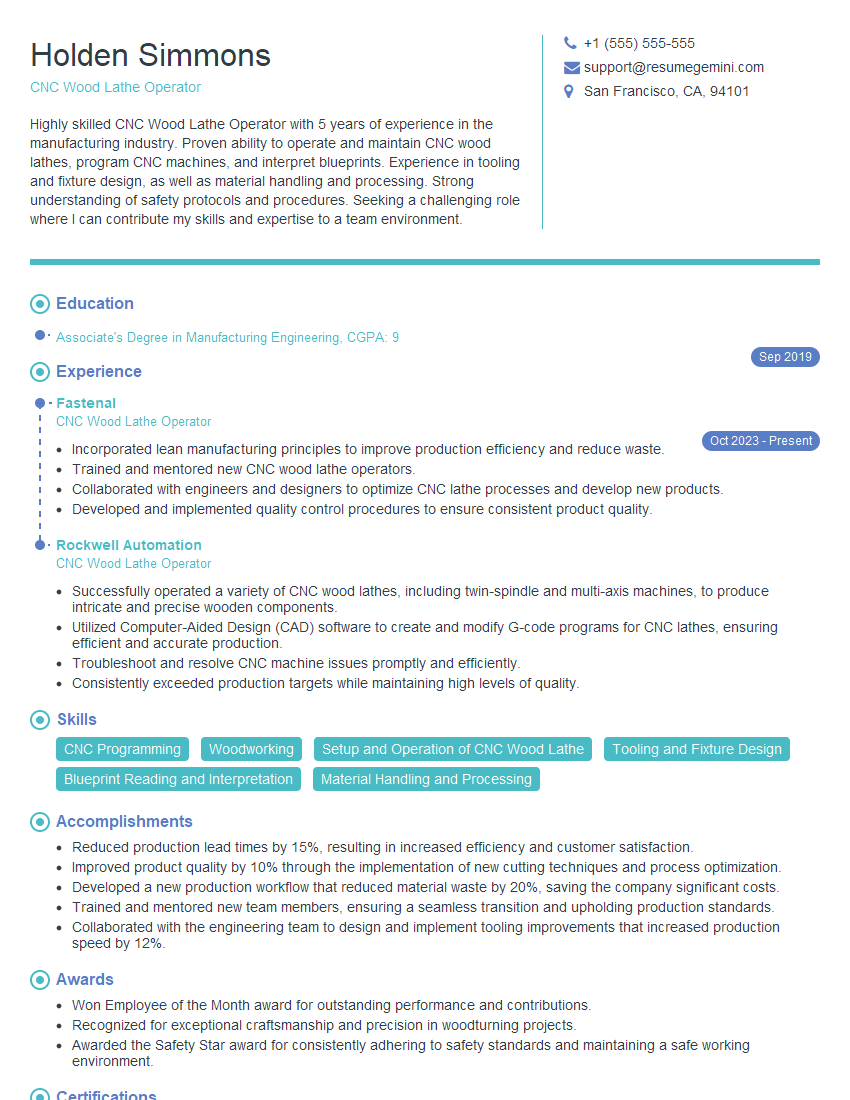

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For CNC Wood Lathe Operator

1. Explain the different types of CNC wood lathes and their applications.

There are two main types of CNC wood lathes: spindle lathes and chuck lathes.

- Spindle lathes are used for turning cylindrical and conical shapes. They have a rotating spindle that holds the workpiece and a tool that moves along the length of the workpiece to cut it.

- Chuck lathes are used for turning more complex shapes, such as bowls and vases. They have a chuck that holds the workpiece and a tool that moves around the chuck to cut it.

2. Describe the process of setting up a CNC wood lathe.

Preparing the Machine

- Install the appropriate cutting tools and accessories.

- Secure the workpiece in the chuck or on the spindle.

- Set the machine’s speed and feed rates.

Creating and Loading the Program

- Create a CNC program using CAM software.

- Transfer the program to the machine’s controller.

3. What are the different types of cutting tools used in CNC wood lathes?

The most common types of cutting tools used in CNC wood lathes are:

- Turning tools are used for cutting the outside diameter of a workpiece.

- Boring tools are used for cutting the inside diameter of a workpiece.

- Facing tools are used for cutting the end of a workpiece.

- Grooving tools are used for cutting grooves into a workpiece.

4. How do you troubleshoot common problems with CNC wood lathes?

Some common problems with CNC wood lathes and their troubleshooting steps include:

- The machine is not cutting properly.

- Check the cutting tool for wear or damage.

- Check the machine’s speed and feed rates.

- The machine is making excessive noise.

- Check the machine for loose parts or bearings.

- Check the cutting tool for wear or damage.

- The machine is not responding to commands.

- Check the machine’s controller for errors.

- Check the machine’s power supply.

5. What are the safety precautions that must be followed when operating a CNC wood lathe?

- Always wear appropriate safety gear, including eye protection, ear protection, and gloves.

- Keep the work area clean and free of debris.

- Never operate the machine while under the influence of alcohol or drugs.

- Follow all manufacturer’s instructions for safe operation.

6. How do you maintain a CNC wood lathe?

- Clean the machine regularly to remove dust and debris.

- Lubricate the machine’s moving parts regularly.

- Inspect the machine’s cutting tools for wear or damage.

- Calibrate the machine’s sensors regularly.

7. What are the advantages of using a CNC wood lathe over a manual wood lathe?

- CNC wood lathes are more accurate and precise than manual wood lathes.

- CNC wood lathes can produce more complex shapes than manual wood lathes.

- CNC wood lathes are faster than manual wood lathes.

- CNC wood lathes are safer than manual wood lathes.

8. What are the different types of materials that can be turned on a CNC wood lathe?

- Wood

- Plastic

- Metal

- Composite materials

9. What are the applications of CNC wood lathes?

- Furniture making

- Musical instrument making

- Tool making

- Prototyping

- Art and sculpture

10. What are the career opportunities for CNC wood lathe operators?

- CNC wood lathe operator

- CNC programmer

- CNC machine setup technician

- CNC maintenance technician

- CNC quality control inspector

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for CNC Wood Lathe Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the CNC Wood Lathe Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

CNC Wood Lathe Operators are responsible for operating and maintaining CNC wood lathes to produce wooden parts and components. Their key responsibilities include:

1. Machine Operation

Operate CNC wood lathes to produce wooden parts and components according to specifications.

- Loading and unloading raw materials, such as logs or lumber, into the lathe.

- Programming the lathe to cut and shape the wood to precise specifications.

- Monitoring the lathe’s operation and making adjustments as needed.

- Inspecting finished products for quality and accuracy.

2. Machine Maintenance

Perform basic maintenance on CNC wood lathes to ensure optimal performance.

- Lubricating and cleaning the lathe regularly.

- Checking and replacing worn or damaged parts.

- Troubleshooting and resolving minor technical issues.

- Reporting any major problems or malfunctions to supervisors.

3. Safety Compliance

Follow all safety protocols and procedures when operating and maintaining CNC wood lathes.

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, earplugs, and gloves.

- Keeping the work area clean and organized.

- Reporting any safety hazards or concerns to supervisors.

- Participating in safety training and refresher courses.

4. Quality Assurance

Ensure that all wooden parts and components produced meet the required quality standards.

- Inspecting finished products for defects or errors.

- Making adjustments to the lathe or production process to improve quality.

- Providing feedback to supervisors on quality issues and improvement opportunities.

- Participating in quality control programs and initiatives.

Interview Tips

Preparing for a CNC Wood Lathe Operator interview requires a combination of technical knowledge and an understanding of the industry. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific CNC Wood Lathe Operator position you are applying for. Understand the company’s products, services, and its reputation in the industry. Familiarize yourself with the job description and highlight the skills and experience that align with the company’s needs.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on trends and developments.

- Network with professionals in the field to gain insights and learn about potential job opportunities.

2. Practice Your Answers

Anticipate common interview questions and prepare your answers. Practice articulating your skills, experience, and qualifications. Emphasize how your abilities align with the job requirements and the company’s needs. Consider using the STAR method to structure your answers, which involves providing specific examples of your Situation, Task, Action, and Result.

- Tell me about your experience working with CNC wood lathes.

- Describe a time when you successfully resolved a technical issue with a CNC wood lathe.

- How do you ensure that the wooden parts and components you produce meet quality standards?

3. Showcase Your Technical Skills

CNC Wood Lathe Operators should possess a solid understanding of CNC programming, machine operation, and maintenance. Highlight your proficiency in these areas, providing specific examples of your work. Discuss your experience with different types of CNC wood lathes, tooling, and software. Emphasize your attention to detail, accuracy, and ability to troubleshoot and resolve technical issues.

- Discuss your experience with different CNC programming languages, such as G-code or ISO code.

- Describe the types of wooden materials you have worked with and how you adjust your programming and techniques accordingly.

- Share examples of how you have used your technical skills to improve efficiency, reduce waste, or enhance product quality.

4. Emphasize Safety and Quality

Safety and quality are paramount in manufacturing environments. Emphasize your commitment to following safety protocols, wearing appropriate PPE, and maintaining a clean and organized work area. Highlight your understanding of quality control processes and your ability to inspect finished products to ensure they meet specifications. Discuss your experience with implementing quality improvement initiatives or participating in quality assurance programs.

- Describe your experience with safety protocols and procedures in a manufacturing environment.

- Share examples of how you have identified and resolved quality issues in your previous roles.

- Discuss your understanding of quality control processes and your ability to implement quality improvement initiatives.

5. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and the company. Prepare questions that show your engagement and curiosity. Inquire about the company’s growth plans, the specific projects you would be involved in, or opportunities for professional development. This step also allows you to assess whether the company is a good fit for your skills and career aspirations.

- What are the company’s plans for growth and expansion in the future?

- Which specific projects would I be involved in as a CNC Wood Lathe Operator?

- What opportunities are there for professional development and training within the company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the CNC Wood Lathe Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!