Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Core Layer Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

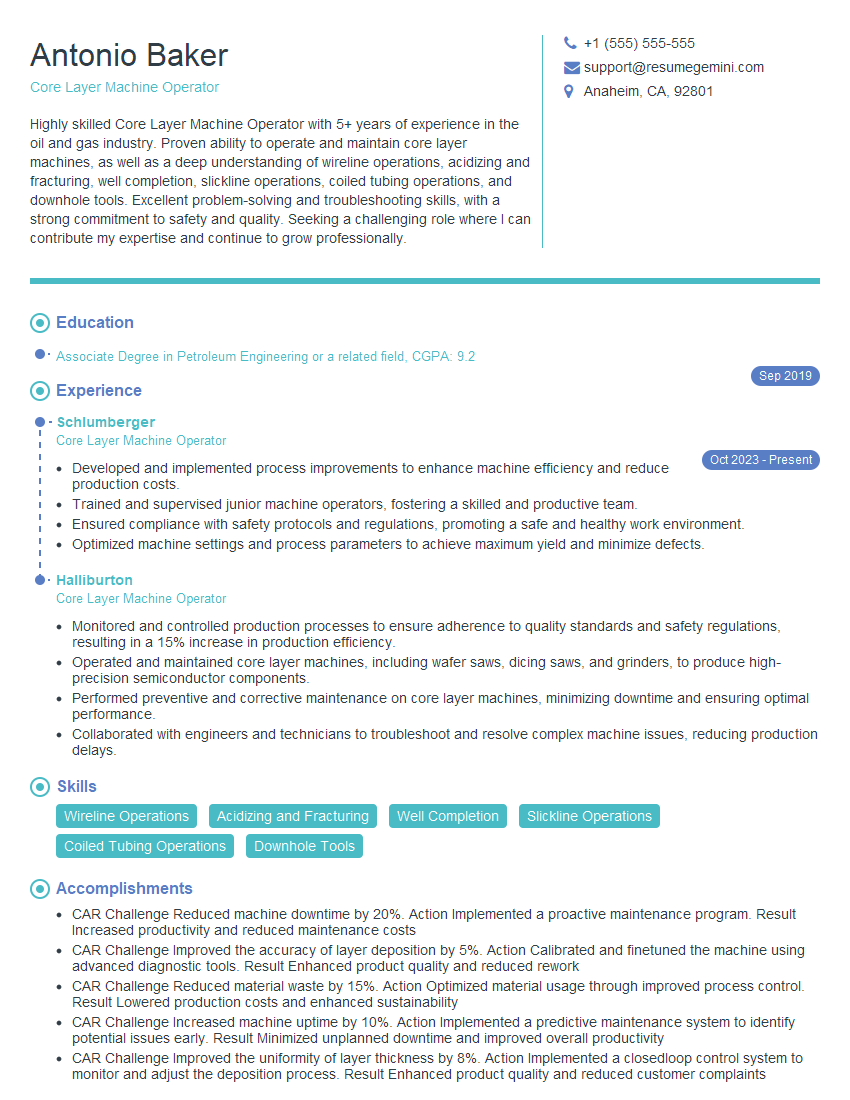

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Core Layer Machine Operator

1. What are the key responsibilities of a Core Layer Machine Operator?

- Operate and maintain core layer machines to produce high-quality products.

- Monitor machine performance and make adjustments as needed to ensure optimal output.

- Troubleshoot and resolve machine malfunctions to minimize downtime.

- Adhere to safety protocols and maintain a clean and organized work area.

2. Describe the different types of core layer machines and their applications.

Core Layer Machines

- Centerless Grinding Machines: Used for high-precision grinding of cylindrical workpieces.

- Cylindrical Grinding Machines: Designed for grinding external and internal cylindrical surfaces.

- Surface Grinding Machines: Suitable for grinding flat surfaces with high accuracy and finish.

Applications

- Automotive Industry: Manufacturing of engine components, transmission shafts, and other precision parts.

- Aerospace Industry: Production of aircraft components, such as landing gear, turbine blades, and fuel system parts.

- Medical Device Industry: Fabrication of surgical instruments, implants, and other medical equipment.

3. What are the critical parameters to consider when setting up a core layer machine?

- Workpiece dimensions and tolerances

- Cutting tool selection and parameters

- Machine speed and feed rates

- Coolant type and flow rate

- Lubrication requirements

4. How do you maintain the accuracy and precision of core layer machines?

- Regular calibration and inspection of machines and tools

- Use of high-quality cutting tools and materials

- Implementation of preventive maintenance schedules

- Monitoring of machine performance through sensors and data analysis

5. What are the common safety hazards associated with operating core layer machines, and how do you mitigate them?

Hazards

- Rotating machinery

- Sharp cutting tools

- High-pressure coolants

- Electrical hazards

Mitigation

- Wearing appropriate personal protective equipment (PPE)

- Following established safety protocols

- Using machine guards and interlocks

- Receiving proper training and certification

6. Describe the process of troubleshooting and resolving common machine malfunctions in core layer operations.

- Identify the symptoms and potential causes of the malfunction.

- Use diagnostic tools and techniques to isolate the issue.

- Implement corrective actions, such as replacing worn parts or adjusting machine parameters.

- Verify the resolution and document the findings.

7. How do you stay up-to-date with the latest advancements in core layer machine technology?

- Attending industry conferences and workshops

- Reading technical journals and publications

- Consulting with machinery manufacturers and experts

- Participating in online forums and discussion groups

8. What is your understanding of quality control and assurance in core layer operations?

- Establishing and maintaining product specifications

- Performing regular inspections and testing to ensure compliance

- Implementing corrective measures to address non-conformance

- Documenting and recording quality data

9. How do you handle multiple simultaneous operations and prioritize tasks?

- Assessing the urgency and importance of each task

- Delegating responsibilities to other team members when possible

- Using project management tools and techniques

- Communicating effectively with colleagues and supervisors

10. Describe a situation where you successfully resolved a complex technical issue in core layer operations.

- Describe the issue and its impact on operations.

- Explain the troubleshooting process and the steps taken to identify the root cause.

- Detail the solution implemented and its effectiveness.

- Mention any lessons learned or best practices that emerged from the experience.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Core Layer Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Core Layer Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Core Layer Machine Operator is responsible for operating and maintaining machinery used to manufacture core layers for electronic devices. These machines use precision processes to create thin, uniform layers of materials essential for the functionality of electronic devices.

1. Machine Operation

The operator is responsible for understanding the operation of the core layer machine and its various components, including the loading and unloading mechanisms, temperature controls, and safety features.

- Perform routine maintenance and calibration on the machine to ensure optimal performance, including cleaning, lubrication, and adjustment.

- Monitor machine performance and identify any issues or deviations from specifications, taking corrective action as necessary.

2. Materials Handling

The operator needs to be familiar with the different materials used in the core layer manufacturing process and their handling procedures.

- Properly load and unload materials, such as wafers, substrates, and chemicals, into the machine according to established procedures.

- Adhere to safety protocols when handling hazardous materials or operating machinery.

3. Quality Control

The operator is responsible for ensuring the quality of the core layers produced by the machine, meeting specifications and standards.

- Inspect the core layers for defects, such as scratches, particles, or contamination.

- Take corrective action to address any quality issues by adjusting machine settings or modifying process parameters.

4. Process Optimization

The operator is expected to continuously improve the core layer manufacturing process by identifying areas for optimization.

- Analyze machine data and identify trends to improve efficiency and reduce waste.

- Collaborate with engineers and technicians to implement process improvements or troubleshoot issues.

Interview Tips

Interviewing for a Core Layer Machine Operator position can be challenging, but with preparation and the right approach, you can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the company and the role

Familiarize yourself with the company’s website, products, and industry standing. Understand the specific responsibilities of the Core Layer Machine Operator role and how it aligns with your skills and experiences.

- Highlight your knowledge of the core layer manufacturing process and the equipment used in the field.

- Demonstrate your understanding of quality control procedures and your commitment to meeting high standards.

2. Practice your answers to common interview questions

Prepare thoughtful answers to common interview questions that showcase your relevant skills and experience. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

- For example, you could describe a time when you identified an issue with a core layer machine and the steps you took to resolve it.

3. Showcase your technical skills

Emphasize your technical abilities and experience with core layer machine operation and maintenance. Highlight your proficiency in troubleshooting, calibration, and process optimization.

- Provide specific examples of how you have used your technical skills to improve efficiency or resolve problems.

- If you have any certifications or training in core layer manufacturing, be sure to mention them.

4. Highlight your attention to detail and quality

As a Core Layer Machine Operator, attention to detail is paramount. Emphasize your strong attention to detail and your commitment to producing high-quality core layers.

- Share examples of your experience in implementing quality control measures or identifying and correcting defects.

- Discuss your understanding of the importance of maintaining a clean and organized work environment.

5. Be enthusiastic and ask questions

Show your enthusiasm for the role and the company. Ask thoughtful questions to demonstrate your interest and engagement. This will also give you an opportunity to gather more information about the position and the company culture.

- Ask about the company’s investment in research and development or their plans for future growth.

- Inquire about opportunities for professional development and training within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Core Layer Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!