Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cork Molder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cork Molder so you can tailor your answers to impress potential employers.

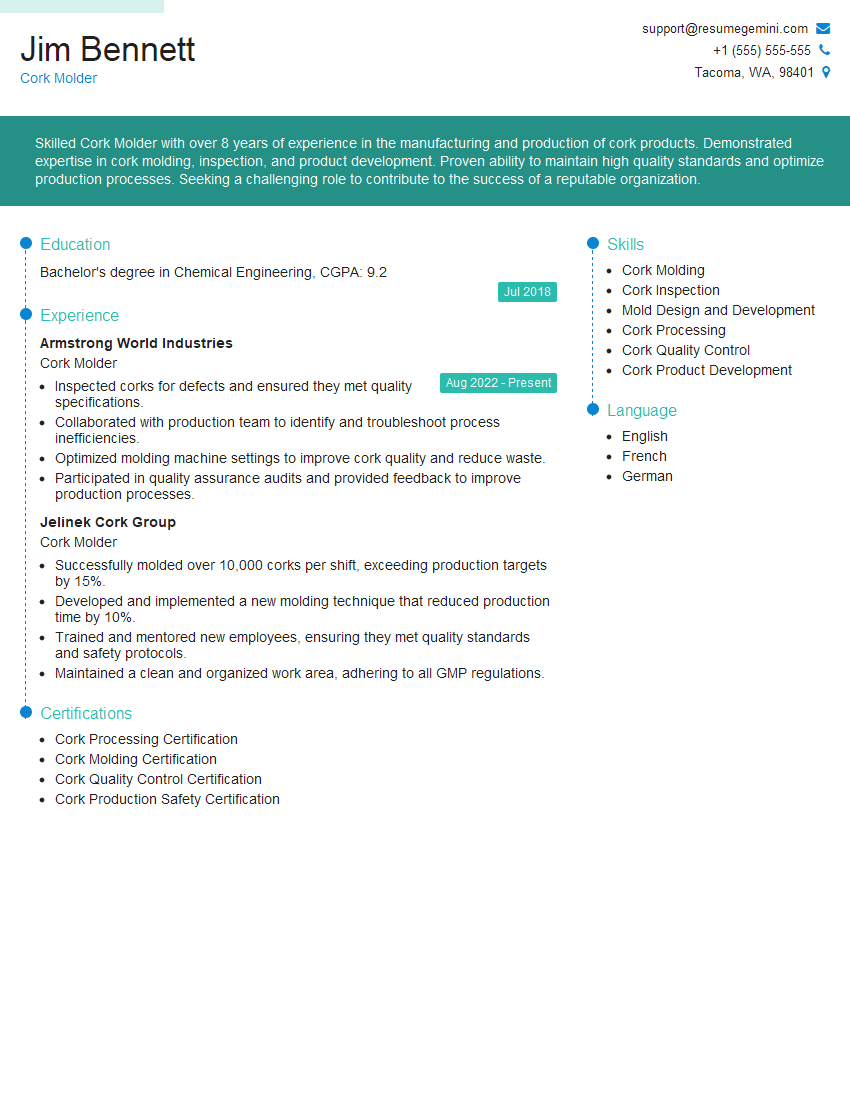

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cork Molder

1. What are the different types of cork materials used in molding and their properties?

- Natural Cork: Lightweight, water-resistant, compressible, good for gaskets and seals.

- Regenerated Cork: Made from recycled cork granules, less expensive, higher density, used in construction.

- Nitrile-Butadiene Cork: Synthetic cork with improved resistance to oils and chemicals, used in automotive and aerospace applications.

- Cork Composites: Blends of cork with other materials like rubber or plastics, customized properties for specific applications.

2. Explain the process of molding cork to create complex shapes.

Compression Molding

- Cork granules are compressed into a heated mold.

- Pressure and heat fuse the cork particles, forming a solid shape.

- Suitable for high-volume production of simple shapes.

Injection Molding

- Molten cork is injected into a mold under high pressure.

- Cork solidifies in the mold, forming complex shapes with fine details.

- Requires specialized equipment and high temperatures.

3. How do you ensure the quality of cork products during molding?

- Raw Material Inspection: Check cork granules for impurities, consistency, and moisture content.

- Process Control: Monitor molding parameters (temperature, pressure, time) and adjust as needed.

- Visual Inspection: Inspect molded products for defects, surface finish, and dimensional accuracy.

- Testing: Perform tests on molded products to verify properties like density, compression strength, and moisture resistance.

4. What are the common defects that can occur in cork molding and how can they be prevented?

- Voids and Cracks: Caused by insufficient pressure or uneven heating, can be prevented by optimizing process parameters.

- Warping: Caused by uneven moisture distribution, can be prevented by proper curing and aging of cork materials.

- Blistering: Caused by trapped air or moisture, can be prevented by using degassed cork materials and proper drying techniques.

- Delamination: Caused by poor adhesion between layers of cork, can be prevented by ensuring proper bonding and surface preparation.

5. How do you calculate the density of molded cork products?

Density = Mass / Volume

- Measure the mass of the molded product using a scale.

- Calculate the volume of the product using geometric formulas or a water displacement method.

- Divide the mass by the volume to obtain the density.

6. What is the importance of curing cork products after molding?

- Stabilizes Dimensions: Allows the cork to shrink and stabilize, reducing future warping or dimensional changes.

- Improves Properties: Curing enhances the mechanical properties of cork, such as strength and flexibility.

- Releases Moisture: Excess moisture from the molding process evaporates, ensuring optimal performance and stability.

7. Describe the different finishing techniques used for cork products and their applications.

- Coating: Applying a layer of paint, varnish, or sealant to protect the cork and enhance its aesthetics.

- Laminating: Bonding thin layers of cork or other materials to the surface for decorative or functional purposes.

- Embossing: Creating raised or sunken designs on the cork surface using pressure or heat.

- Staining: Altering the color of the cork using dyes or stains, enhancing its appearance or matching specific designs.

8. What are the environmental considerations in cork molding and how can they be addressed?

- Sustainable Harvesting: Ensuring that cork oak trees are harvested responsibly and sustainably.

- Recycled Materials: Using recycled cork materials to reduce waste and conserve resources.

- Energy Efficiency: Optimizing molding processes to minimize energy consumption and reduce carbon emissions.

- Biodegradability: Cork is a biodegradable material that can be disposed of sustainably, minimizing environmental impact.

9. Explain how the hardness of cork products can be adjusted during molding.

- Binder Type: Using different binders can affect the hardness of the final product.

- Compression Pressure: Higher compression pressure during molding increases hardness.

- Cork Particle Size: Finer cork particles result in a harder product.

- Mixing Ratio: Adjusting the ratio of cork to binder can influence hardness.

10. What is the role of antioxidants in cork molding and why are they important?

- Prevent Degradation: Antioxidants protect cork from oxidation, which can cause discoloration, embrittlement, and loss of properties.

- Extend Shelf Life: Antioxidants help preserve the quality of cork products during storage and use.

- Maintain Color: Antioxidants prevent browning or yellowing of cork, preserving its natural appearance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cork Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cork Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cork Molder is responsible for the production of cork products by operating and maintaining cork molding machines. They ensure the quality of the finished products and adherence to established production schedules.

1. Machine Operation and Maintenance

Cork molders operate and maintain cork molding machines to produce a variety of products, such as wine corks, bottle stoppers, and cork insulation. They monitor the machines to ensure proper operation and make necessary adjustments.

- Operate and maintain cork molding machines.

- Monitor machines to ensure proper operation and make necessary adjustments.

- Troubleshoot and repair machine malfunctions.

2. Quality Control

Cork molders inspect raw materials and finished products to ensure that they meet quality standards. They use a variety of tools and techniques to identify and correct defects.

- Inspect raw materials and finished products to ensure that they meet specifications.

- Identify and correct defects.

- Maintain quality control documentation.

3. Production Planning and Scheduling

Cork molders work with production supervisors to plan and schedule production runs. They determine the appropriate materials, machines, and processes to use, and they monitor progress to ensure that deadlines are met.

- Work with production supervisors to plan and schedule production runs.

- Determine the appropriate materials, machines, and processes to use.

- Monitor progress to ensure that deadlines are met.

4. Safety and Compliance

Cork molders follow all safety regulations and procedures. They wear appropriate protective gear, and they work in a safe and efficient manner.

- Follow all safety regulations and procedures.

- Wear appropriate protective gear.

- Work in a safe and efficient manner.

Interview Tips

Preparing for a cork molder interview requires research on the company, the position, and the industry. Practicing common interview questions and answers can help you feel more confident and increase your chances of success.

1. Research the Company and Position

Before the interview, it’s important to learn about the company’s history, mission, values, and products or services. You should also review the job description and identify the key responsibilities and qualifications for the cork molder position.

- Visit the company’s website and social media pages.

- Read news articles and press releases about the company.

- Review the job description carefully.

- Identify the key responsibilities and qualifications for the position.

2. Practice Common Interview Questions

There are a number of common interview questions that you may be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s helpful to practice answering these questions in advance so that you can deliver your responses confidently and concisely.

- Prepare answers to common interview questions, such as:

- “Tell me about yourself.”

- “Why are you interested in this position?”

- “What are your strengths and weaknesses?”

- Practice your answers out loud in front of a mirror or with a friend or family member.

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the cork molder position. Use specific examples to demonstrate your abilities and how you have applied them in previous roles.

- Quantify your accomplishments whenever possible.

- Use the STAR method to answer interview questions.

- STAR stands for Situation, Task, Action, Result.

4. Ask Questions

At the end of the interview, be sure to ask the interviewer any questions that you have about the position or the company. This shows that you are engaged and interested in the opportunity.

- Prepare a few questions to ask the interviewer.

- Questions can be about the company, the position, or the industry.

- Asking questions shows that you are interested in the opportunity.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cork Molder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.